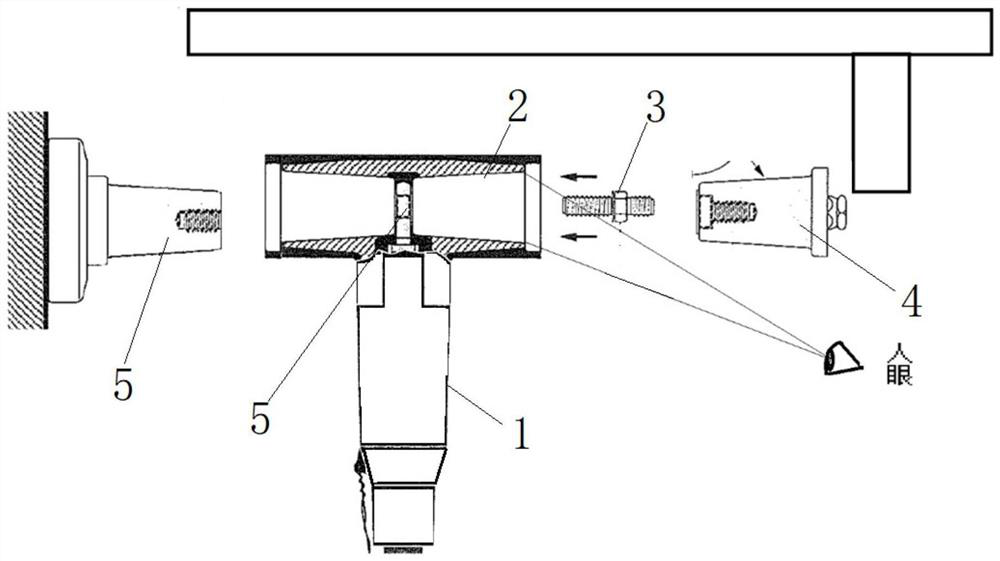

A T-shaped head and its stud installation method

A technology of stud bolts and plugs, which is applied in the field of electric locomotive transformer installation, can solve the problems of insufficient installation torque, affecting the running quality of the locomotive, and affecting the tightening torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

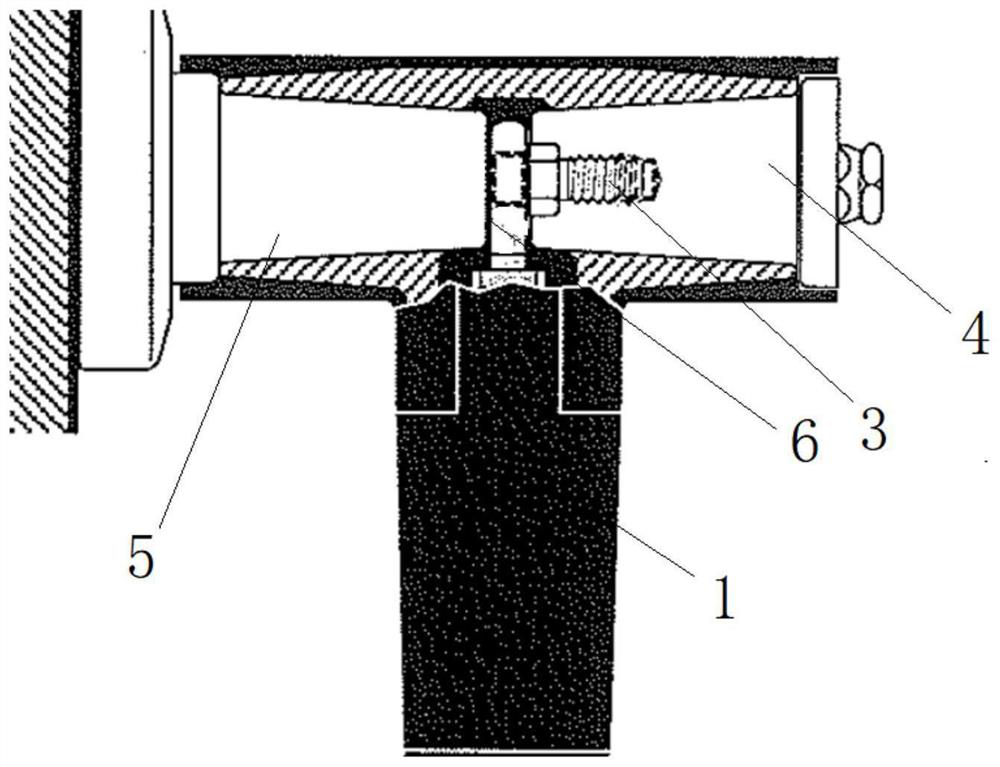

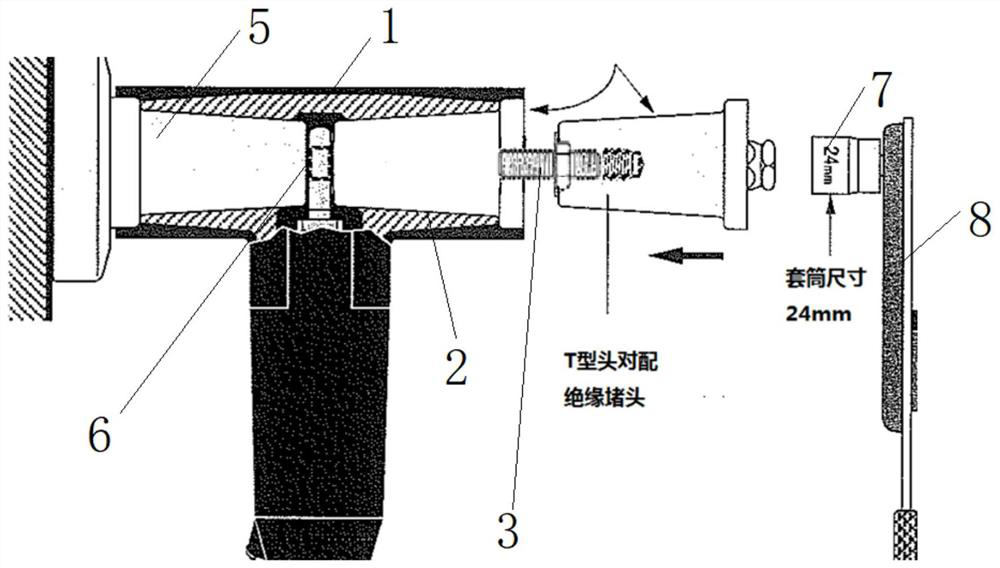

[0047] like Figure 4-Figure 6 As shown, this embodiment discloses a method for installing the T-shaped head 1, including:

[0048] Wrap the insulating plug well with a dust-free wipe and set it aside. During the whole process, the insulating plug is required not to directly contact the ground and dust.

[0049] Use a dust-free wiping cloth and anhydrous ethanol to wipe off the grease inside the boot cover 2 and the insulating plug, and then apply new grease on the surface of the insulating plug 4 and the inner surface of the boot cover 2.

[0050] Install stud bolts 3 and insulating plugs:

[0051] Install the short end of the stud bolt 3 and the insulating plug first.

[0052] The stopper washer is installed on the long end side of the stud bolt 3, and the conical surface of the stopper washer faces the stud bolt 3 side.

[0053] Install the insulating plug and the stud bolts 3 into the shoe cover 2, and the installation torque is 50N·m.

[0054] Then remove the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com