Slider type throwing bridge plug

A slideway-type, drop-off technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as low suspension capacity, early drop-off pressure, etc., to improve water shutoff and The efficiency of sealing the well, eliminating the effect of losing hands in advance and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

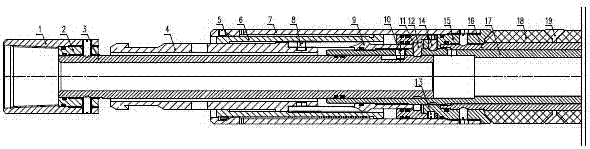

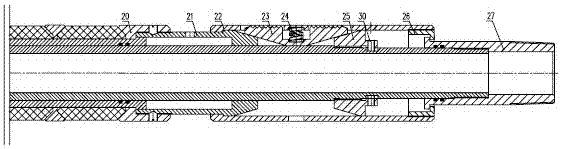

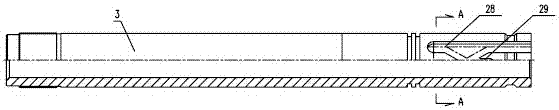

[0015] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

[0016] figure 1 It is the structural representation of the present invention Figure 1 , figure 2 It is the structural representation of the present invention Figure II , image 3 yes figure 1 Schematic diagram of the structure of the middle and upper central tube, Figure 4 yes image 3 A cross-sectional view in the direction of A-A, Figure 5 It is a schematic diagram of laying the outer wall of the upper central tube. As shown in the figure, a slideway-type drop-in bridge plug includes an upper joint 1, a connecting head 2, an upper central tube 3, a fishing head 4, a retaining spring 5, and a working cylinder 6 , upper connecting sleeve 7, unsealing pin 8, throwing hands 9, sliding pin 10, setting piston 11, locking block 1 12, setting pin 13, locking block 2 14, rubber cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com