Assembly device for stacking a fuel cell stack

A fuel cell stack and assembly device technology, applied in the direction of fuel cells, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

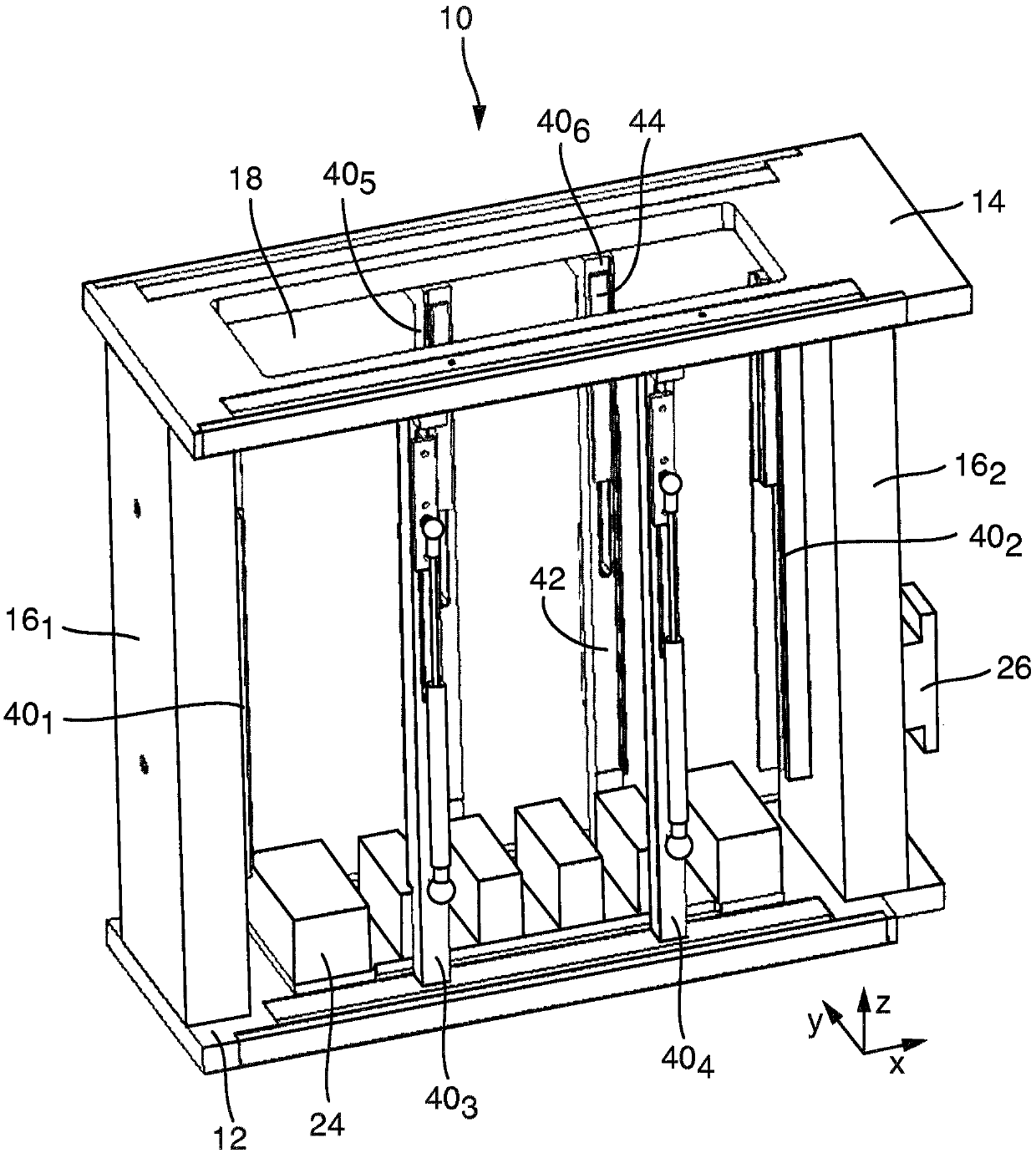

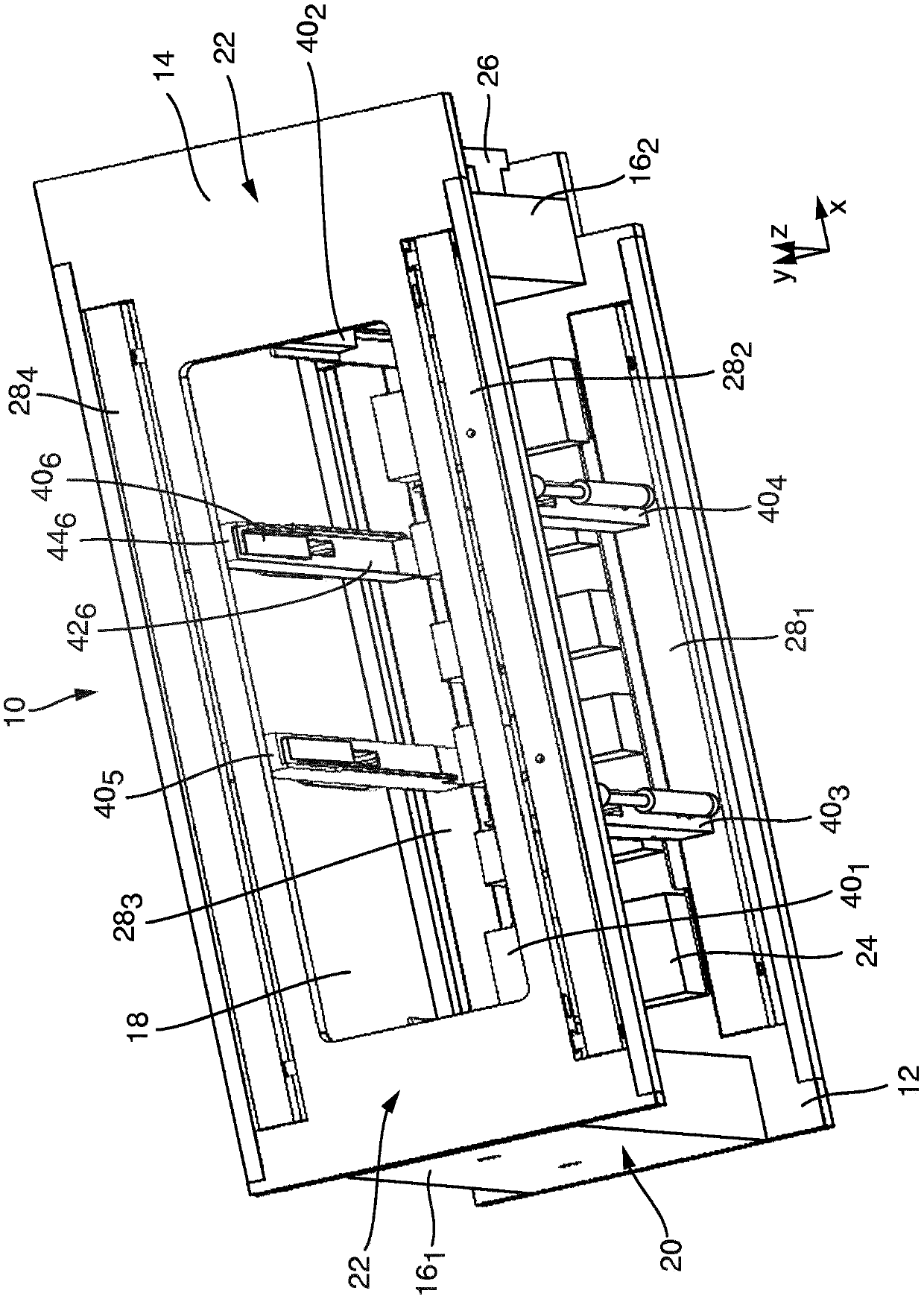

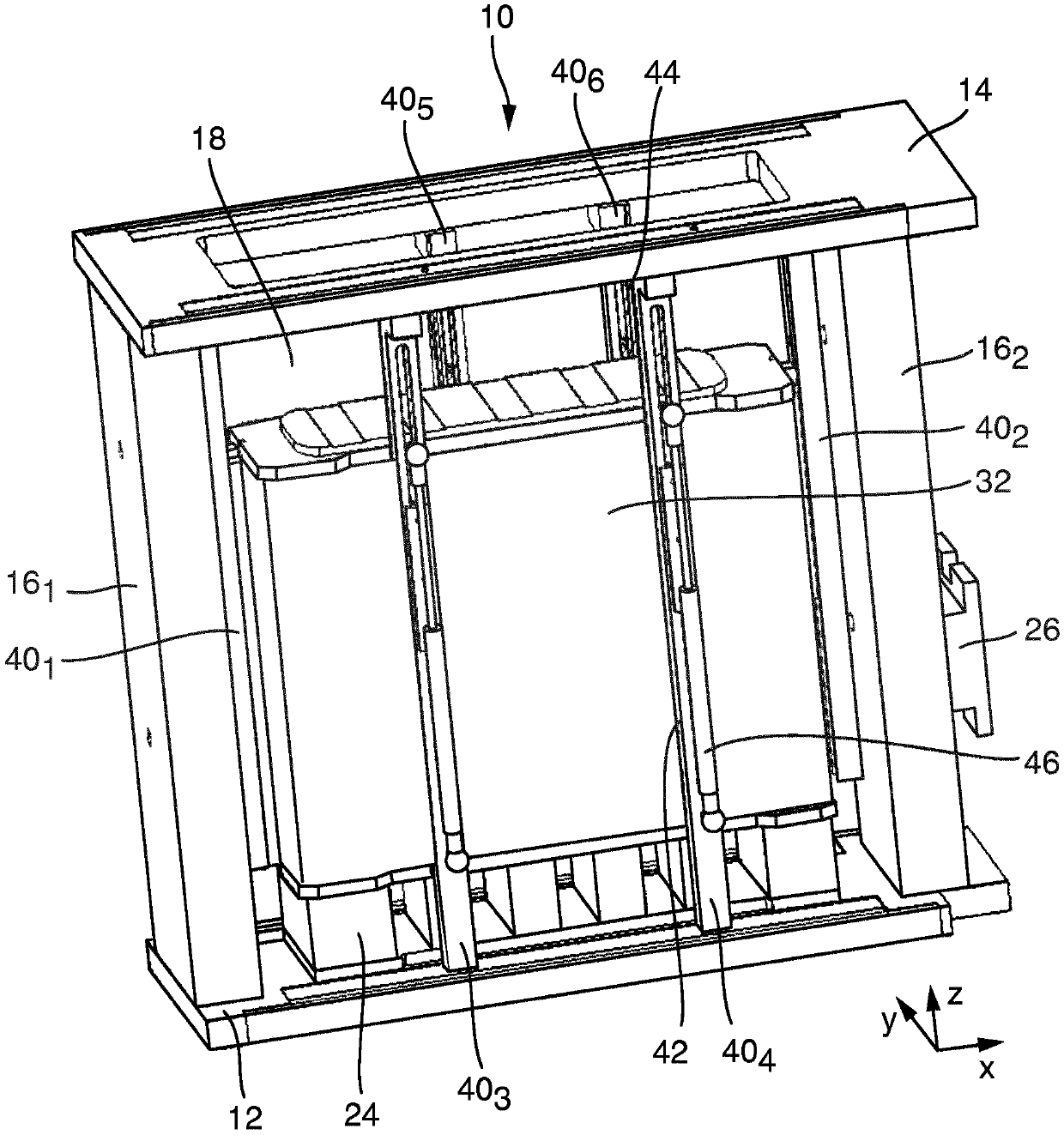

[0024] figure 1 An assembly device 10 according to the invention is shown, which depicts an assembly aid for producing a fuel cell stack. The assembly device 10 consists of a base plate 12, a cover plate 14, and connecting pieces 16 extending on both sides between the base plate 12 and the cover plate 14 1 and 16 2 . The base plate 12 includes a component housing portion 24 housing a fuel cell stack to be stacked. The component receiving portion 24 is vertically adjustable in the height direction within the assembly device 10 . Connector 16 1 、16 2 At least one of them may comprise a contact plate 26 via which the assembly device 10 may be held and moved by a manipulator (not shown, eg a robot). To describe the direction, in figure 1 A rectangular coordinate system is shown in , which has an x-direction, a y-direction, and a z-direction. Based on this, the z direction represents the vertical direction, and the x and y directions represent the horizontal direction.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com