A self-protection cylindrical permanent magnet transmission device

A permanent magnet transmission and self-protection technology, which is applied in electromechanical transmission, electromechanical devices, electric components, etc., can solve problems such as ineffective protection, difficult heat dissipation, and large radius of high-power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

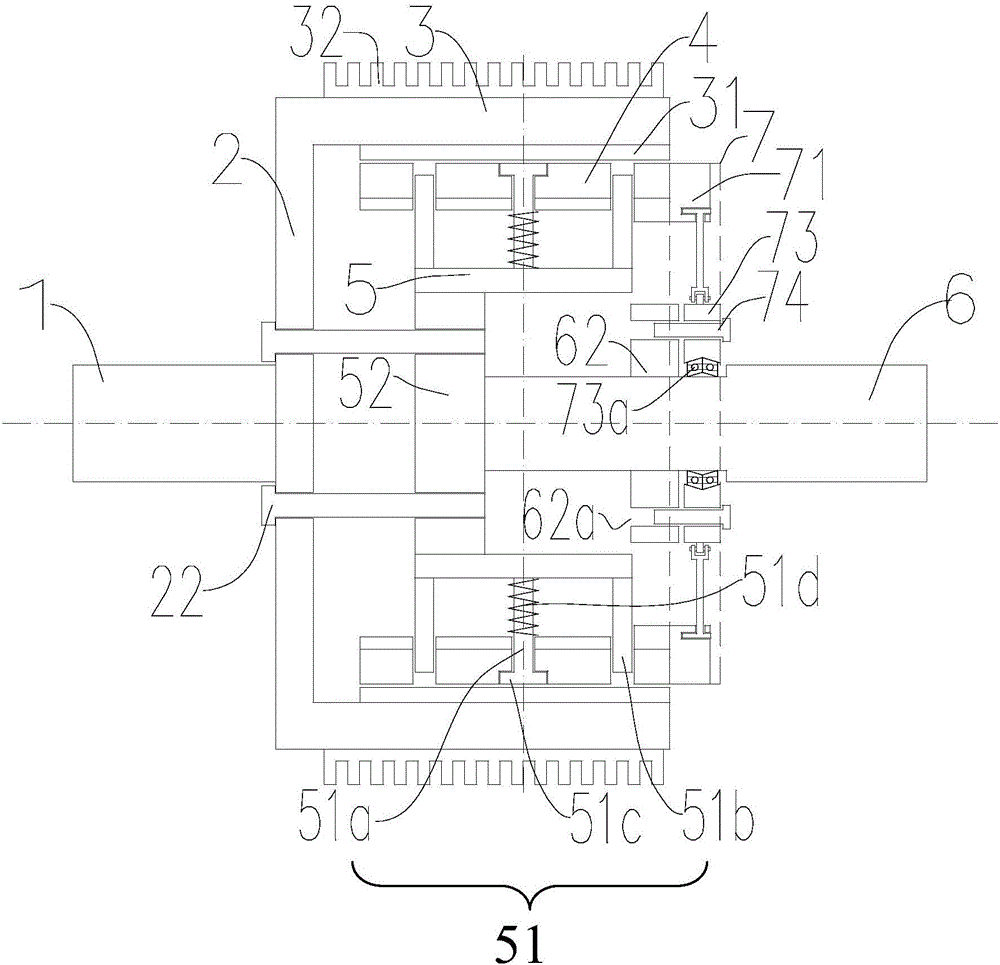

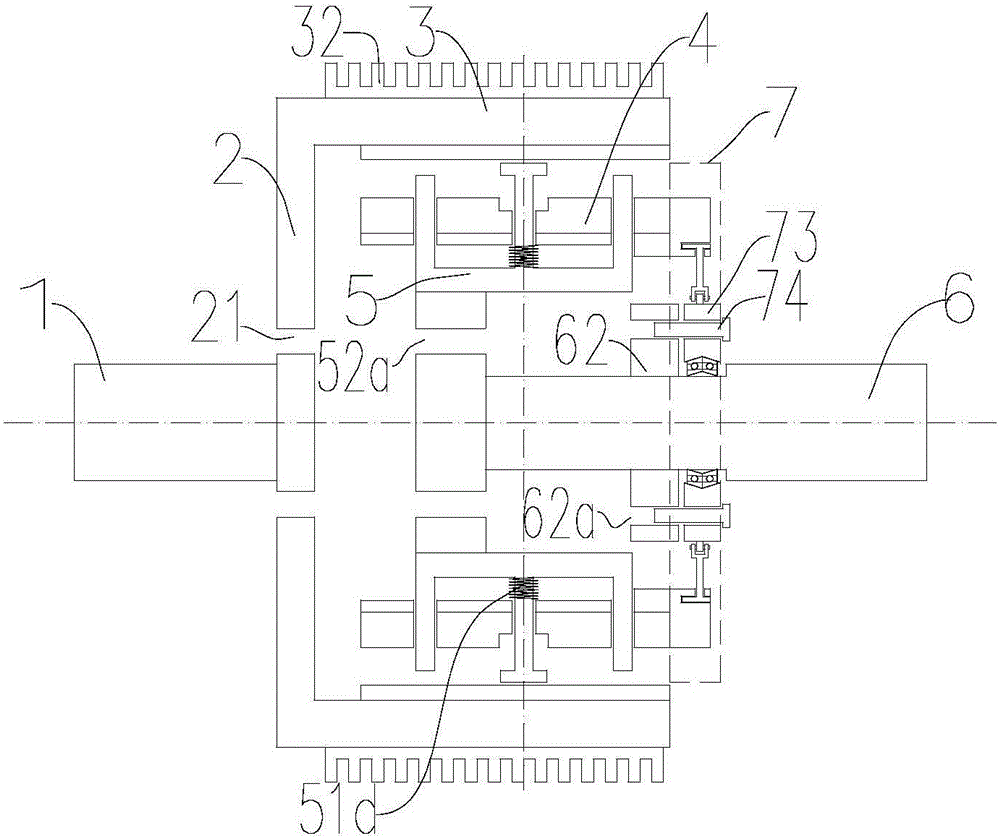

[0038] Figure 1 to Figure 10 , the reference signs are as follows:

[0039] 1. Outer rotor shaft;

[0040] 2. Outer rotor end plate; 21. Outer rotor end plate through hole; 22. Synchronization pin;

[0041] 3. Outer rotor movement cylinder; 31. Conductive metal cylinder; 32. First heat sink;

[0042] 4. Inner rotor rotating cylinder; 41. Permanent magnet; 42. Aluminum disc; 43. Permanent magnet back iron;

[0043] 5. Inner rotor inner rotating cylinder; 51. Fixed rod group; 51a. Main rod; 51b. Secondary rod; 51c. Rod cap; 51d. Centrifugal spring;

[0044] 6. Inner rotor shaft; 61. Axial groove; 62. Shaft flange; 62a. Shaft flange through hole;

[0045] 7. Fan-shaped cylinder push-pull mechanism; 71. Sector-shaped disk; 71a. Sector-shaped disk belt groove; 72. Air gap adjustment rod; 72a. Pull rod pin; 73. Rotary disk; 73a. 73c. Rotating disk through hole; 74. Lock pin.

[0046] Such as figure 1 As shown, a variable air gap self-protection barrel type permanent magnet spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com