Milk maker and coffee machine

A milk and steam technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as the choice of coffee taste that cannot be satisfied, and achieve the effect of meeting different needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

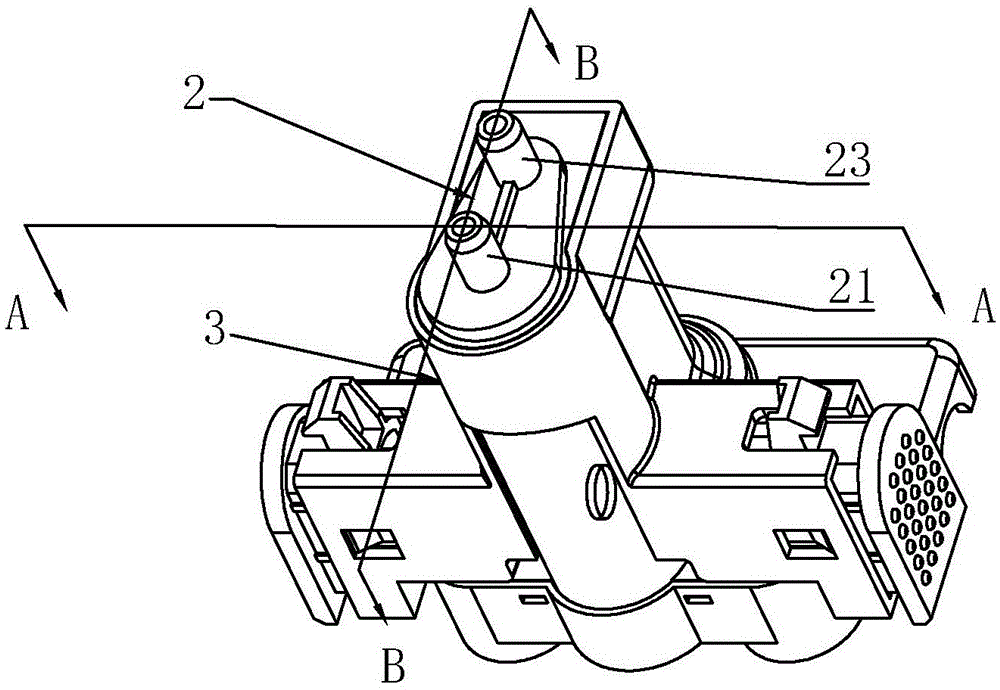

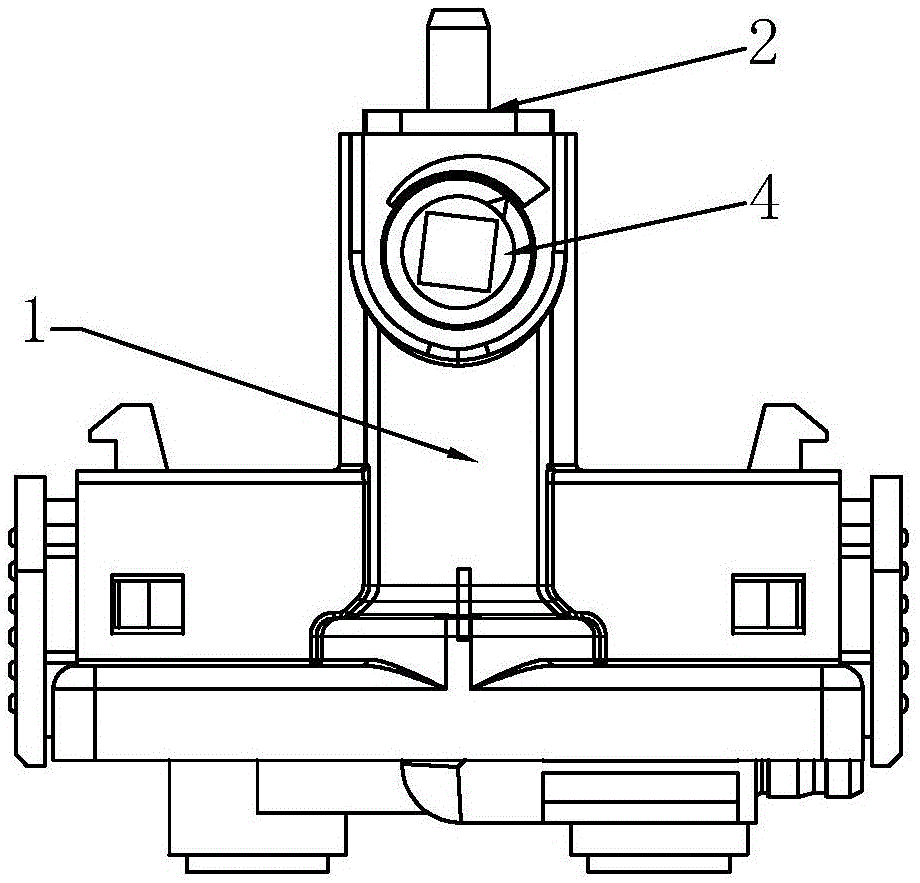

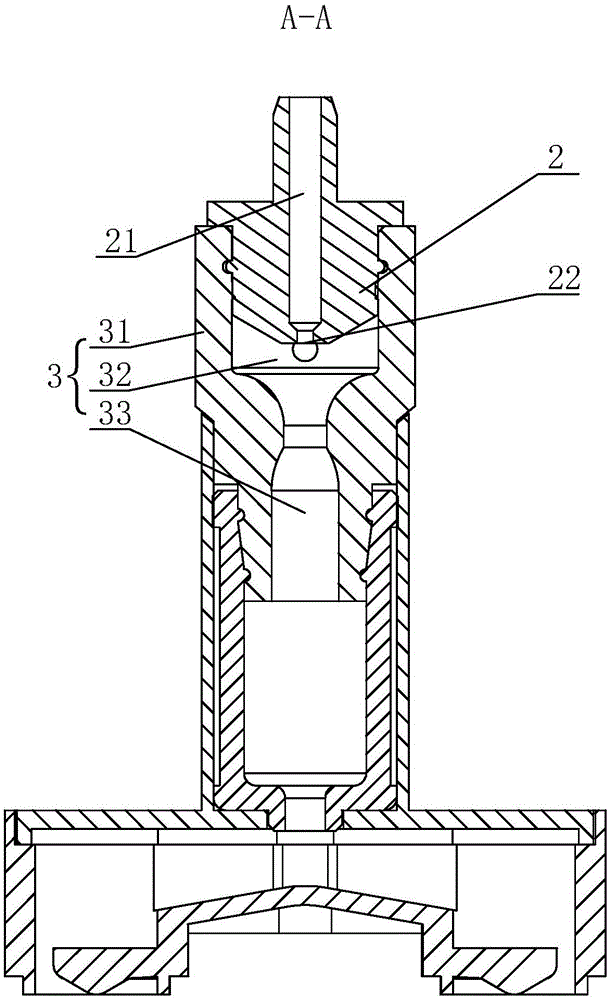

[0020] like Figure 1 to Figure 6 As shown, a milk extractor according to the present invention includes a milk input device 1 for providing milk, a steam input device 2 for providing steam and a mixing device 3 for mixing milk. Both the milk input device 1 and the steam input device 2 are installed on the mixing device 3 , and the milk input device 1 has a milk input channel 11 . The steam supply device 2 has a steam supply channel 21 and an air supply channel 23 . The mixing device 3 includes a mixing device body 31, a mixing chamber 32 provided in the mixing device body 31 for mixing milk and steam, and a milk output communicating with the mixing chamber 32 provided on the mixing device body 31 Channel 33. The mixing chamber 32 communicates with the milk input channel 11, the steam input channel 21 and the air input channel 23 respectively. An air valve 24 is installed on the air input channel 23. When the air valve 24 is opened, air is input through the air input chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com