Metal sheet stacking and flattening device

A metal sheet and pressure-bearing device technology, applied in the field of metal sheet hot rolling, can solve the problems of low production efficiency and difficult flattening devices, and achieve the effects of high production efficiency, good lifting synchronization, and easy upgrading and transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

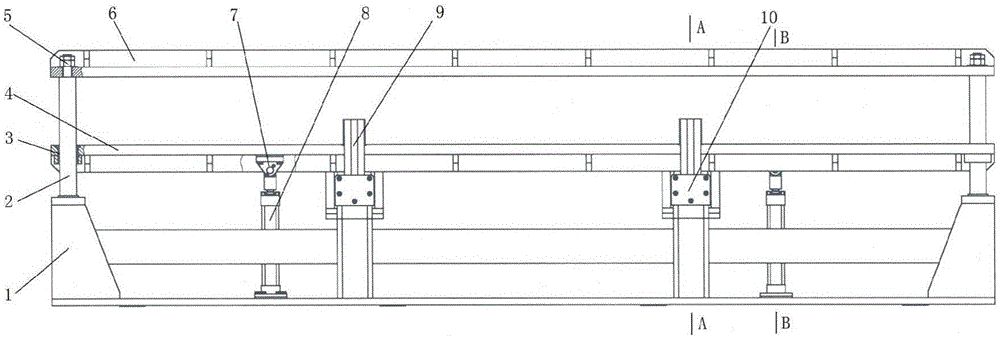

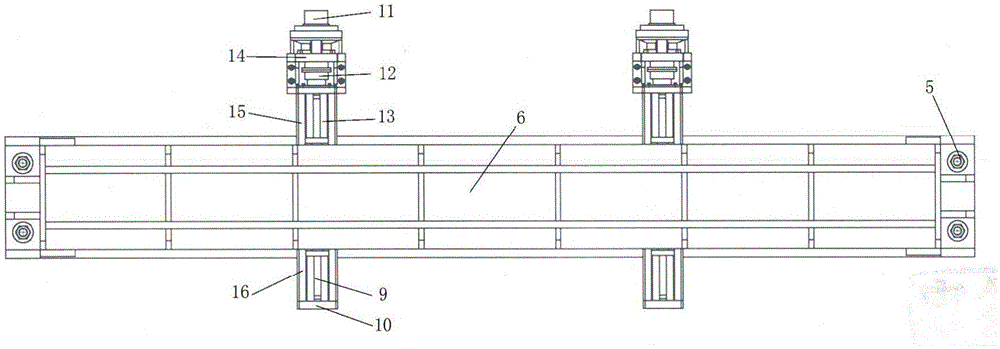

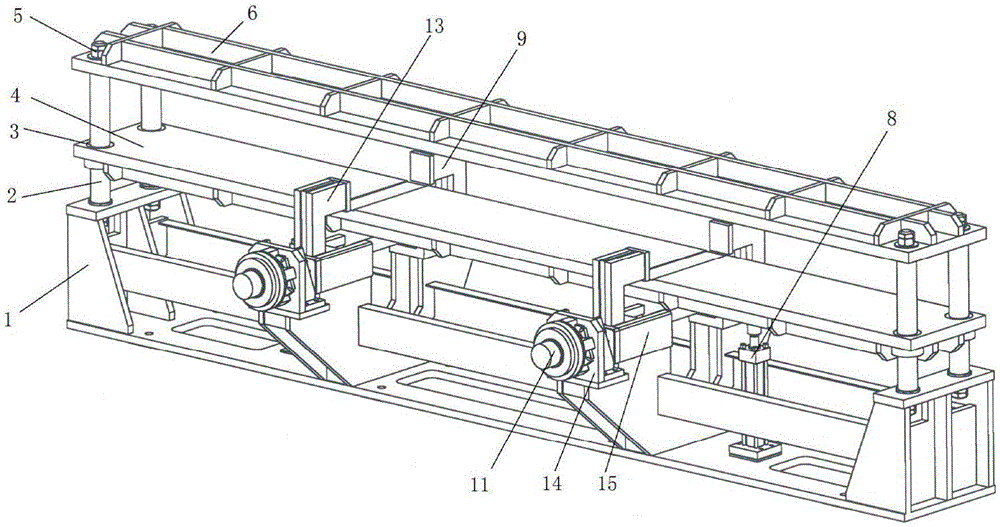

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0023] Such as figure 1 , 2 , 3, 4, 5 and 6, the present invention includes a frame body 1, 4 guide posts 2 are located above the frame body 1, the guide posts 2 pass through the sliding sleeve 3 and the fixed pressure plate 6 is fixed by the nut 5, and the sliding sleeve 3 is embedded In the round holes at the four corners of the lifting pressure plate 4, two cylinder head seats 7 are symmetrically located on both sides of the equipment and installed on the lower side of the lifting pressure plate 4. connection, the bottom of the oil cylinder 8 is fixedly installed on the bottom plate of the frame body 1, two left guide grooves 15 and two right guide grooves 16 are symmetrically welded on the frame body 1, and guide key grooves are processed on the upper inner side, and the guide key 24 is in the guide key groove Sliding inside, the guide key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com