Electric rivet nut tool

A technology for rivet nuts and tools, applied in the field of electric rivet nut tools, can solve problems such as difficult to meet the reliability requirements of assembly tools, motor strain, complex structure, etc., to maintain riveting efficiency, simplify maintenance and error detection, and simplify transmission parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

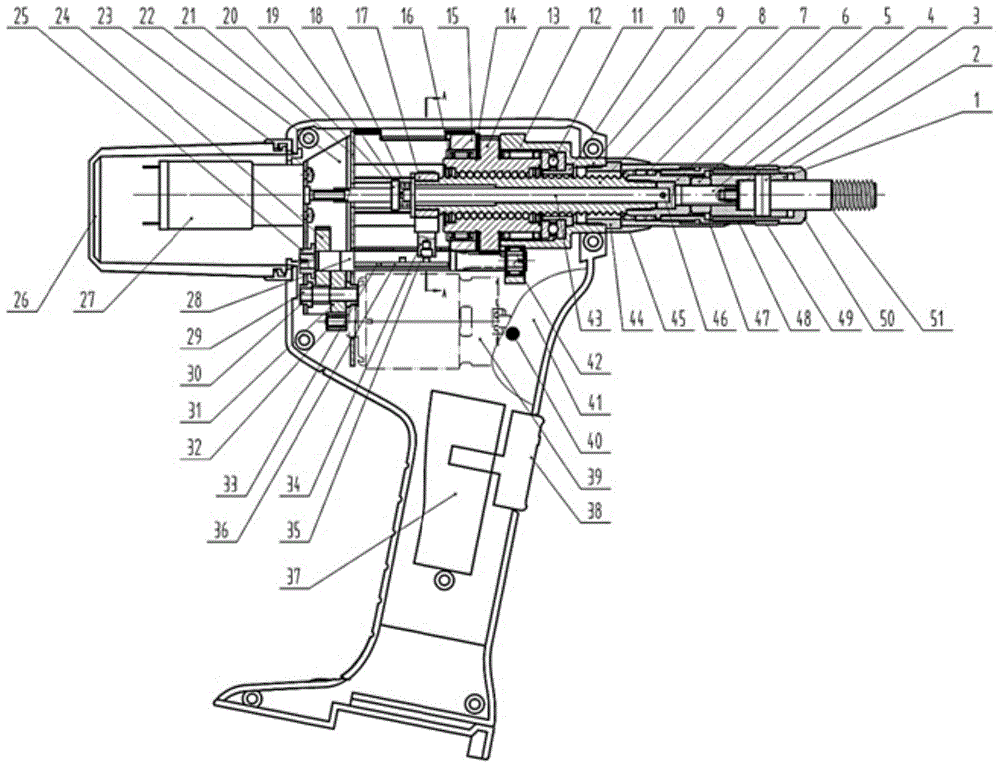

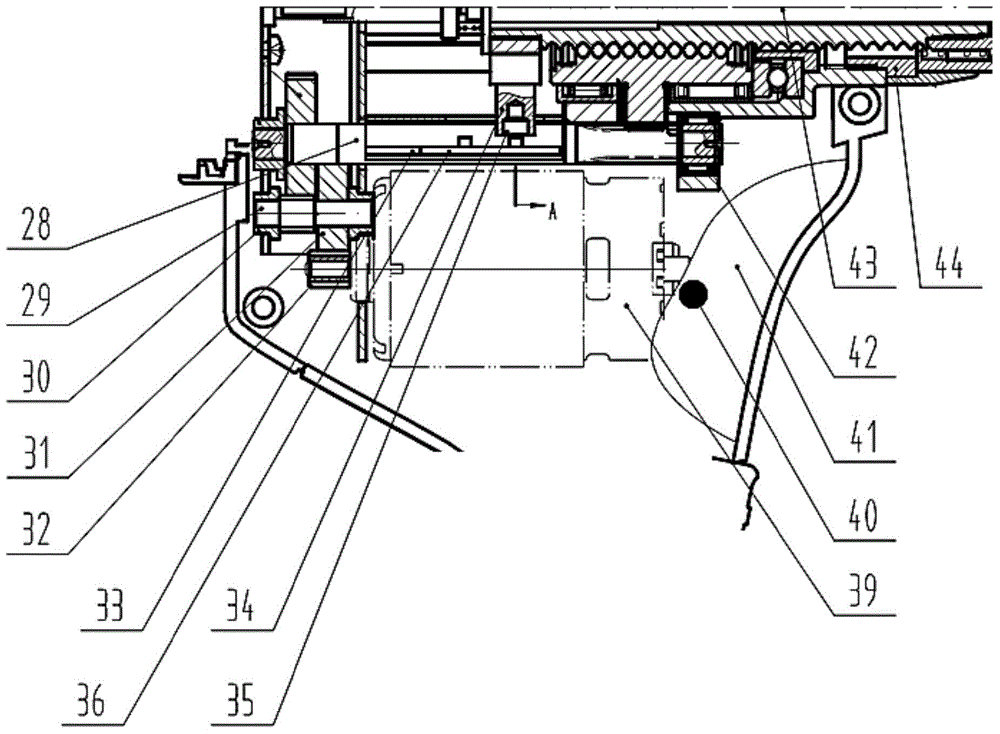

[0022] As shown in Figure 1, this embodiment includes: a casing 41 and a rivet nut axial rotation mechanism arranged inside it, a rivet nut pulling power mechanism, a rivet nut pulling mechanism and a control mechanism, wherein: the control mechanism is connected with the rivet nut respectively. The nut axial rotation mechanism is connected with the rivet nut pulling power mechanism, and the rivet nut axial rotation mechanism and the rivet nut pulling power mechanism are respectively connected with the rivet nut pulling mechanism.

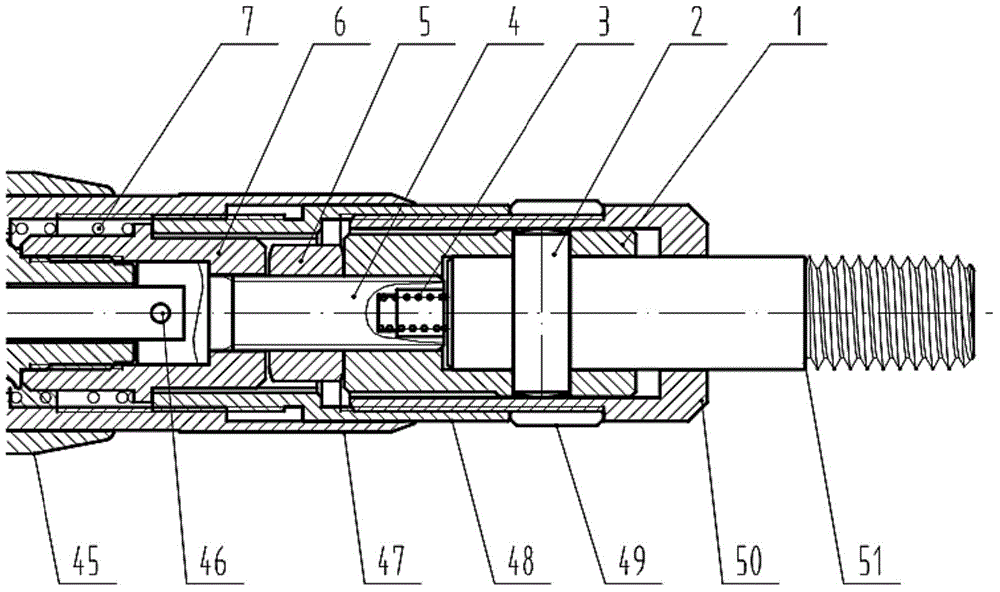

[0023] The rivet nut drawing mechanism includes: the pull rod 6, the connecting sleeve 3, and the connecting pin 4 connected in sequence drive the drawing screw 51, wherein: the outside of the pull rod 6 is connected with the riveting power mechanism of the rivet nut, and the inside is connected with the rivet nut. The nut is connected to the axial rotation mechanism.

[0024] The control mechanism includes: a control board 37 and an action button ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com