Mobile self-supply substation electrified water flushing auxiliary flushing robot system and method

A robot system and robot technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as difficult cleaning of insulators, high labor intensity, hidden safety hazards, etc., to improve cleaning efficiency and automation level, reduce labor intensity, and meet the effect of operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

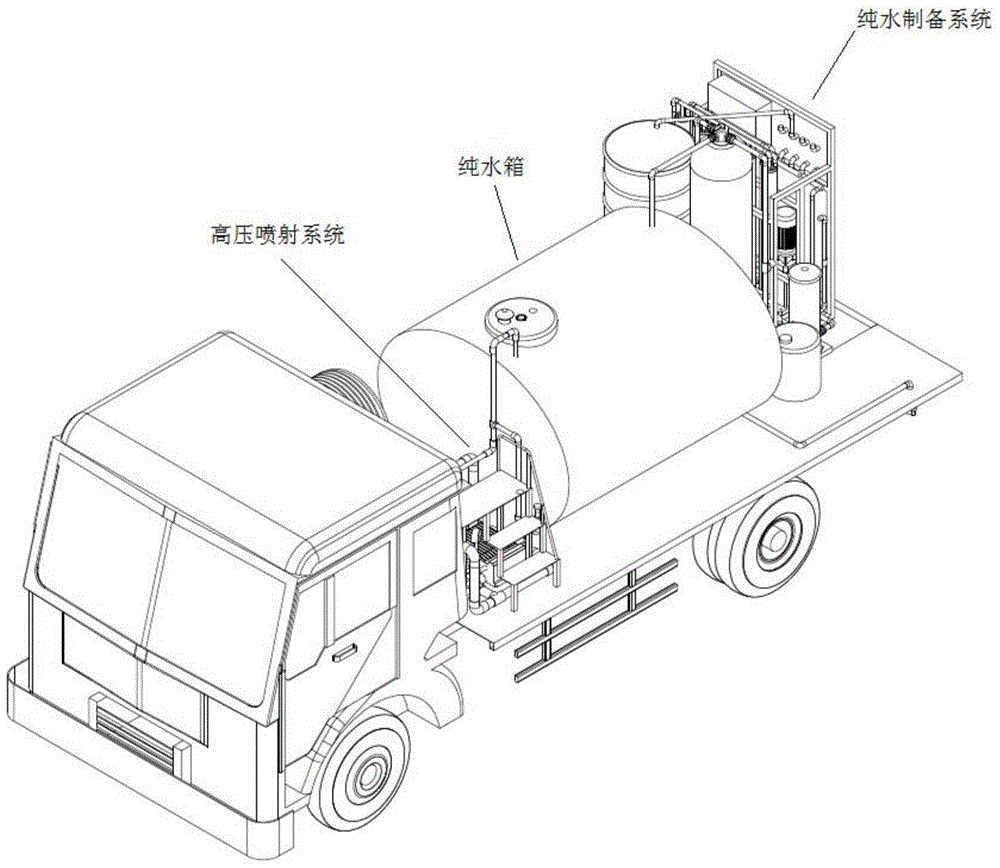

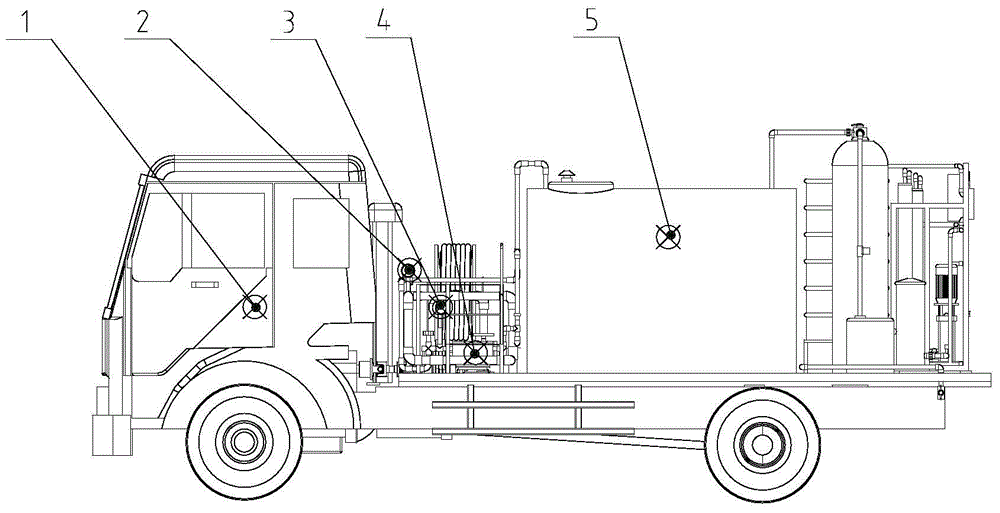

[0038] Mobile self-supplied substation powered water flushing auxiliary flushing robot system, including water flushing system and auxiliary flushing robot, water flushing system includes pure water preparation system and high-pressure injection system; pure water preparation system is connected with high-pressure injection system, high-pressure injection system and auxiliary flushing system The flushing robot is connected through a high-pressure pipeline; the high-pressure water from the hose reel is directly connected to the high-pressure water inlet pipe of the auxiliary flushing robot through a quick-change joint.

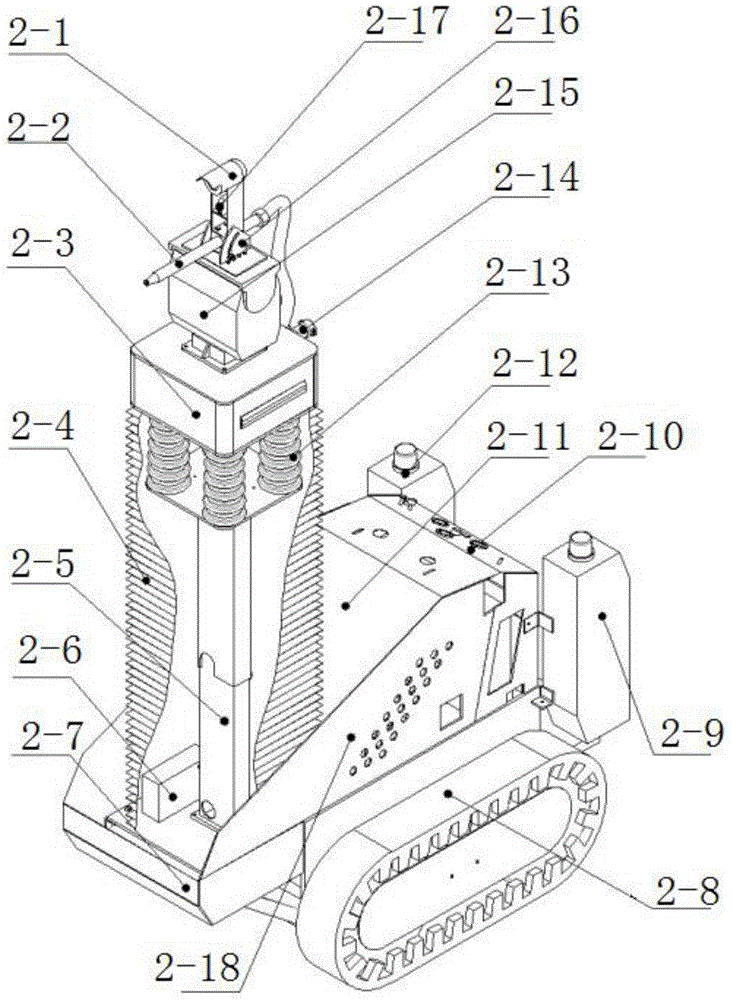

[0039] The structure diagram of the auxiliary punching robot is as follows: figure 1 As shown, the auxiliary flushing robot system includes a car body traveling mechanism 2-8, a power assembly 2-11, a vertical lifting mechanism 2-5, a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com