Elevator brake release device

A technology of elevator brakes and brakes, which is applied in hoisting devices, transportation and packaging, elevators, etc., can solve problems such as inability to guarantee personnel safety, failure of electric brake release, failure of main engine to release brakes, etc., and achieves high synchronization and installation space requirements Small, the effect of avoiding electrical failure failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

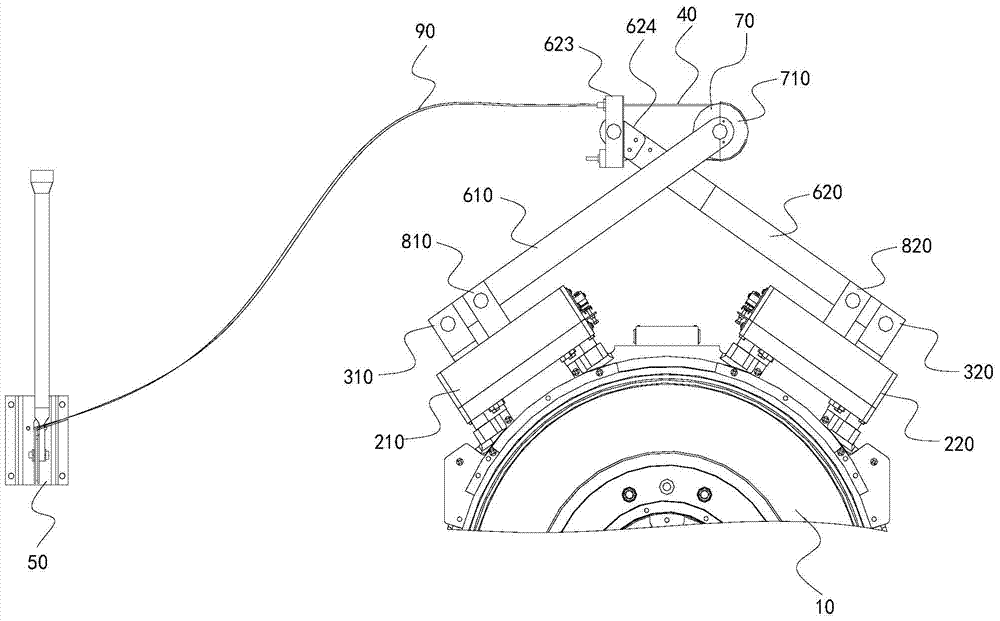

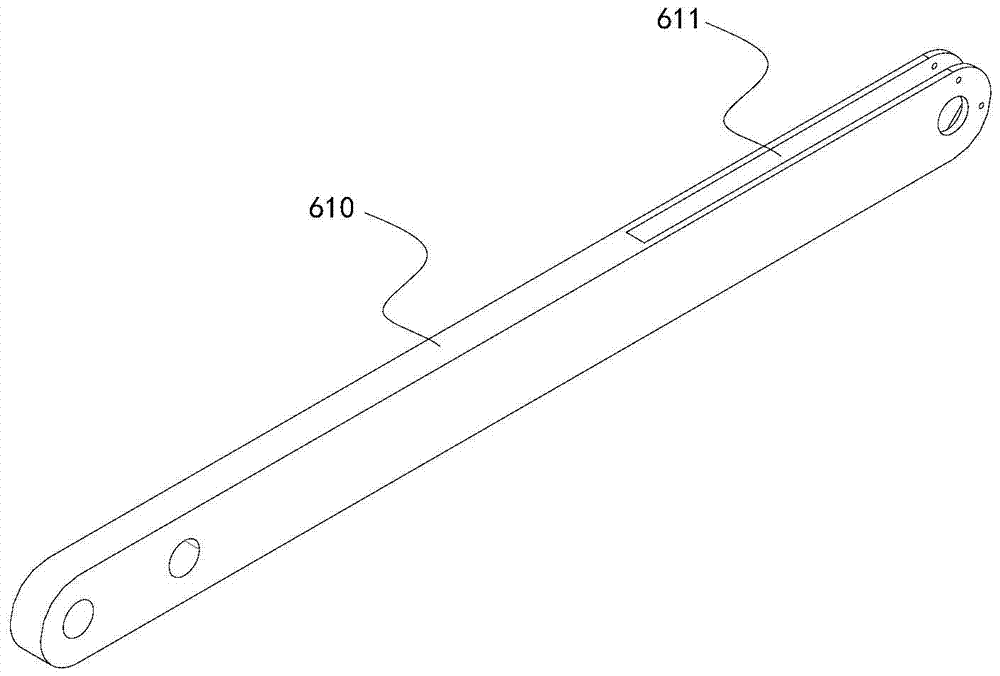

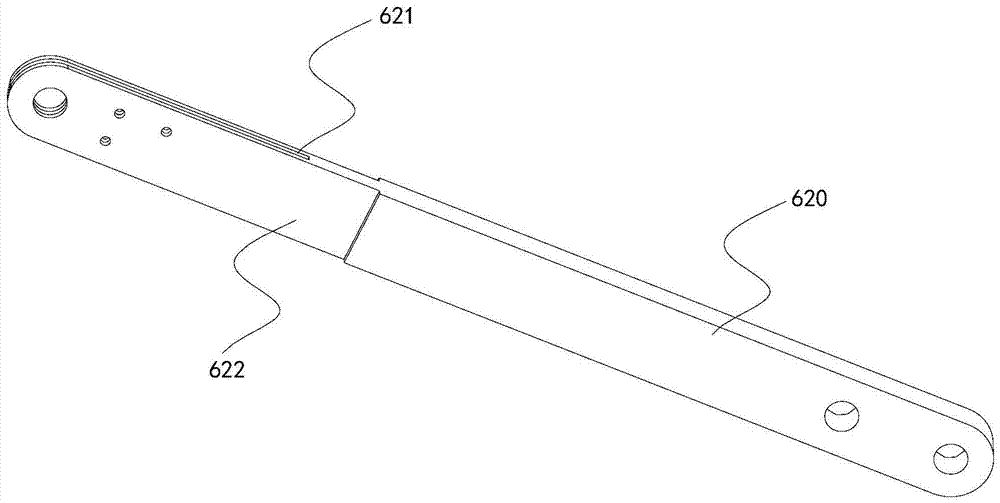

[0028] Such as Figure 1 to Figure 3 As shown, a brake release device for an elevator includes a first brake 210 and a second brake 220, a first support 310 and a second support 320 symmetrically arranged on the elevator host 10, and it also includes a control rope 40, a The out-of-hole brake release operating mechanism 50 for tightening or loosening the control rope 40, the first pull rod 610 and the second pull rod 620 arranged crosswise, one end of the first pull rod 610 is rotatably connected to the first support 310, and the other end is connected to a pulley 70. The first pull rod 610 is provided with an active groove 611, one end of the second pull rod 620 is movably connected with the second support 320, the other end passes through the active groove 611 and is connected with one end of the control rope 40, and the other end of the control rope 40 is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com