Rotary compressor and its crankshaft

A technology for rotating compressors and crankshafts, applied in the field of compressors, can solve the problems of increased wear of crankshafts and bearings, stricter requirements on magnetic permeability, and increased operating resistance of compressors, so as to reduce gas resistance, reduce weight, and reduce The effect of eccentric mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

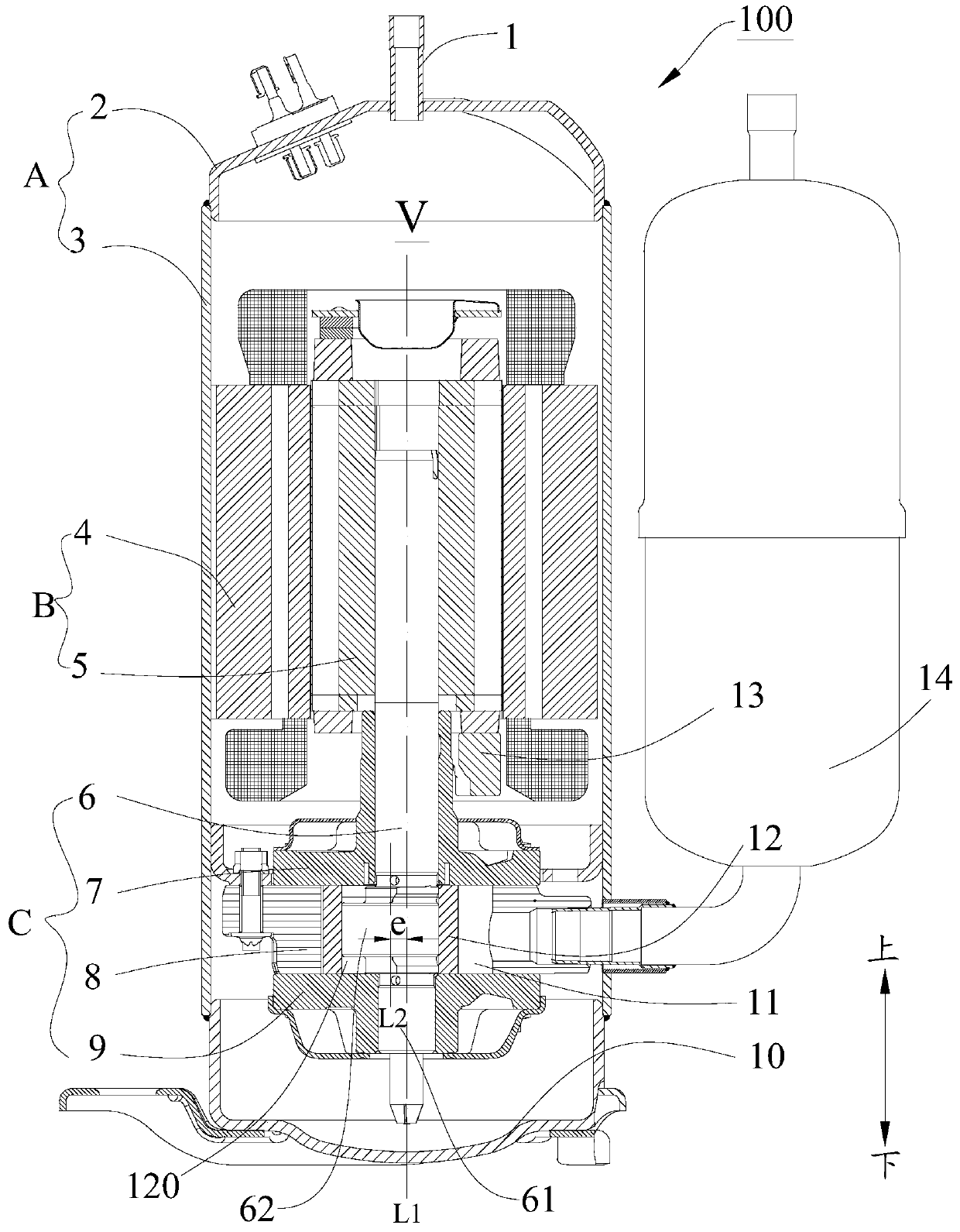

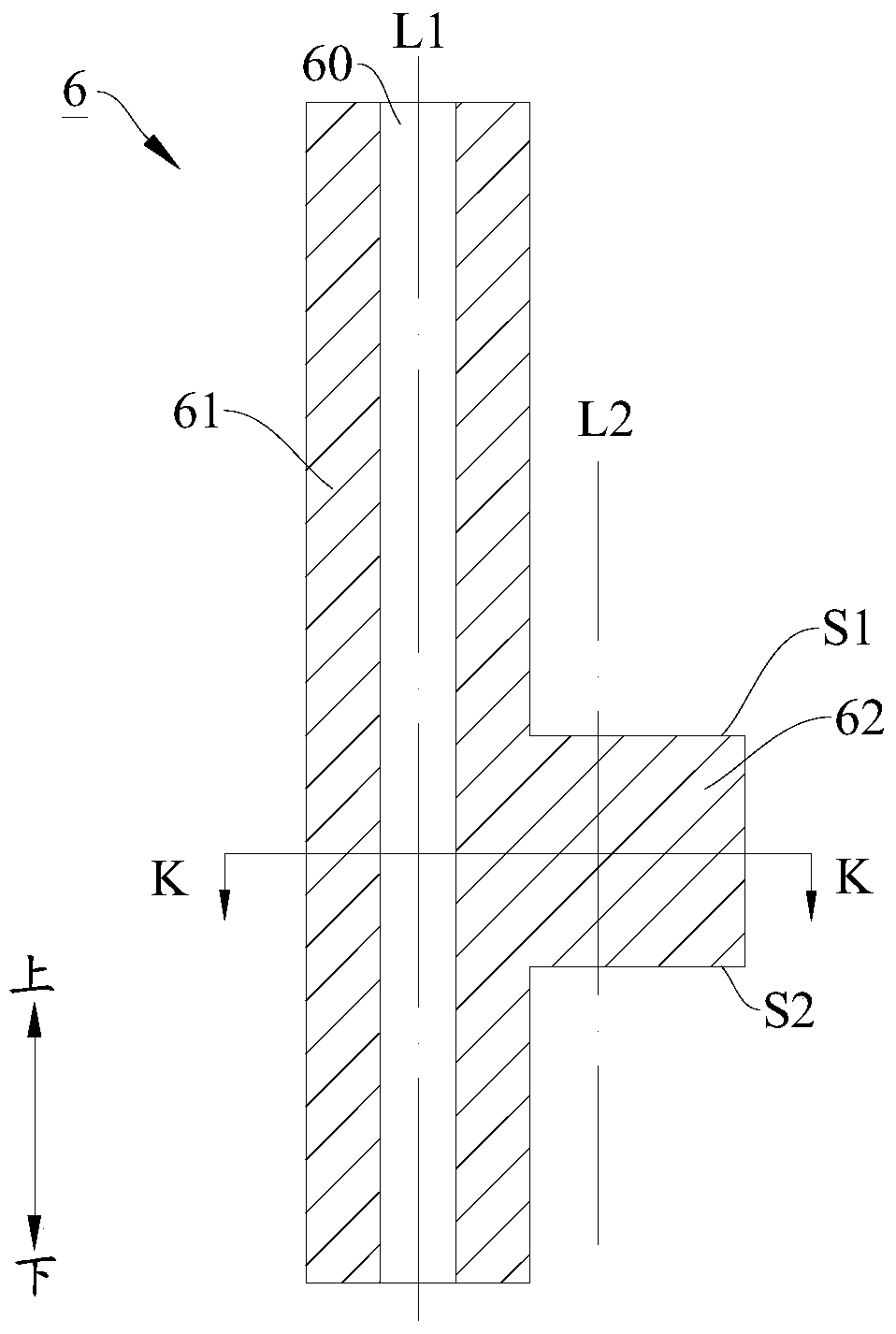

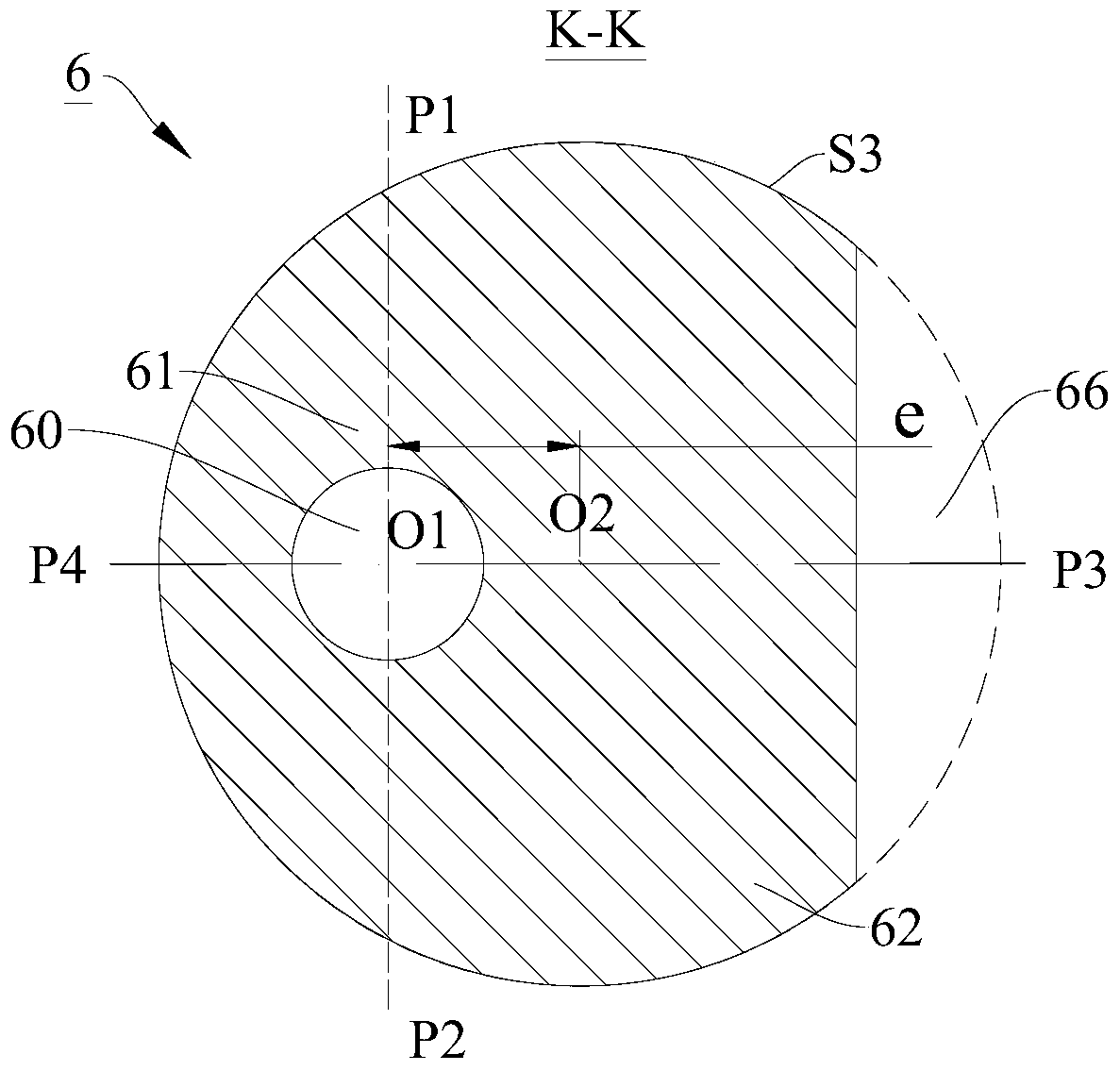

[0056] In this example, if figure 2 with image 3 As shown, the trimming portion 66 passes through the upper end surface S1 and the lower end surface S2 of the eccentric portion 62 .

[0057] Advantageously, the cut plane formed by the trimming portion 66 on the eccentric portion 62 is parallel to the central axis L1 of the main shaft portion 61 . That is to say, the trimming portion 66 is formed tangentially on the eccentric portion 62 by a plane parallel to the central axis L1 of the main shaft portion 61 , and the cross section of the trimming portion 66 is arcuate. Therefore, the trimming portion 66 is more convenient to process, the production cost of the crankshaft 6 is lower, and the eccentric mass of the eccentric portion 62 can be greatly reduced. Wherein, the cross-section of the trimming portion 66 refers to a cross-sectional profile formed on the trimming portion 66 on a plane perpendicular to the central axis L1 of the main shaft portion 61 .

[0058] Of cours...

Embodiment 2

[0061] In this example, if Figure 4 with Figure 5 As shown, the structure of the crankshaft 6 is substantially the same as the structure of the crankshaft 6 in the first implementation, and this will not be repeated.

[0062] The difference is that in the second embodiment, the eccentric part 62 is provided with a weight-reducing balance hole 63 , so that the eccentric mass of the eccentric part 62 can be greatly reduced.

[0063] Specifically, the weight-reducing balance hole 63 is a through hole penetrating the eccentric portion 62 up and down, thus, the processing of the weight-reducing balance hole 63 is more convenient, and the production cost of the crankshaft 6 is lower. In the first embodiment, the cross-sectional shape and cross-sectional area of the weight-reducing balance hole 63 remain unchanged along the axial direction of the crankshaft 6 , which ensures that the manufacturing process of the crankshaft 6 is relatively simple.

[0064] More specifically, as ...

Embodiment 3

[0068] In this example, if Image 6 with Figure 7 As shown, the structure of the crankshaft 6 is substantially the same as the structure of the crankshaft 6 in the first implementation, and this will not be repeated.

[0069] The difference is that, in the third embodiment, the weight-reducing balance hole 63 further includes: side weight-reducing holes 632 , which are located on both sides of the central weight-reducing hole 631 and are symmetrical about the second longitudinal plane P3P4. Therefore, the rotary eccentric inertial force of the rotary compressor 100 using the crankshaft 6 is further reduced, the vibration and noise of the compressor are reduced, and the weight of the balance weight 13 in the compressor is conveniently reduced.

[0070] Advantageously, one end of each side weight-reducing hole 632 extends to the first longitudinal plane P1P2, so that the cross-sectional area of the weight-reducing balance hole 63 is larger, and the eccentric mass of the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com