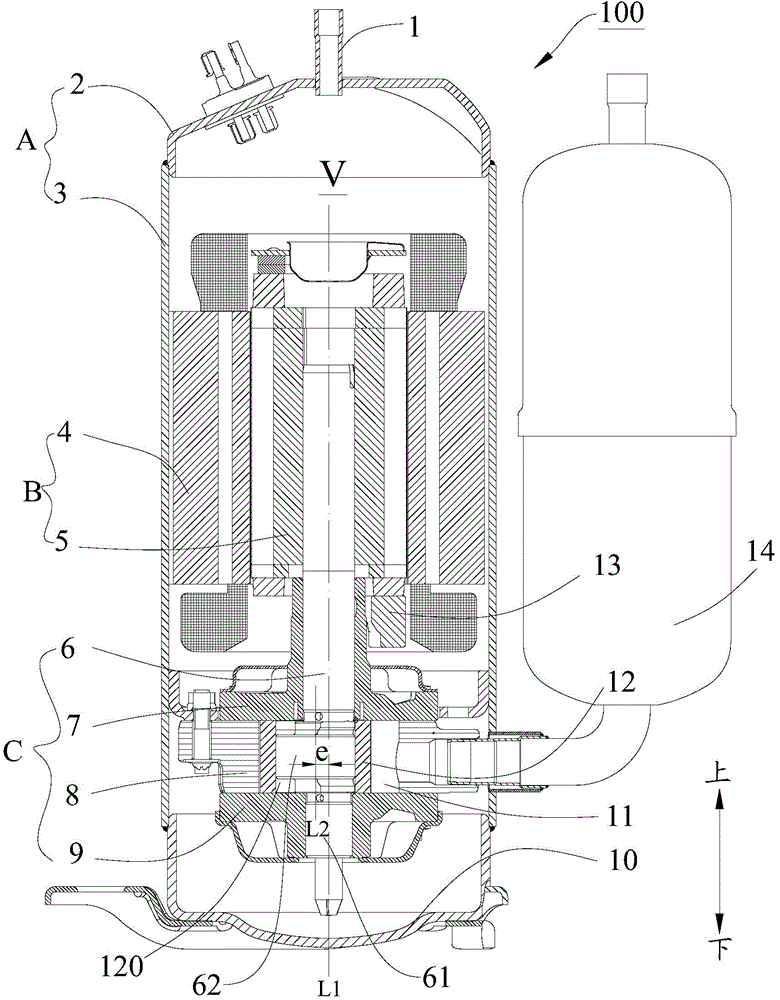

Rotary compressor and crankshaft thereof

A technology for rotating compressors and crankshafts, applied in the field of compressors, can solve the problems of increasing the running resistance of compressors, increasing wear of crankshafts and bearings, and stricter requirements on magnetic permeability, and reducing gas resistance and rotating eccentric inertial force. The effect of reducing, reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

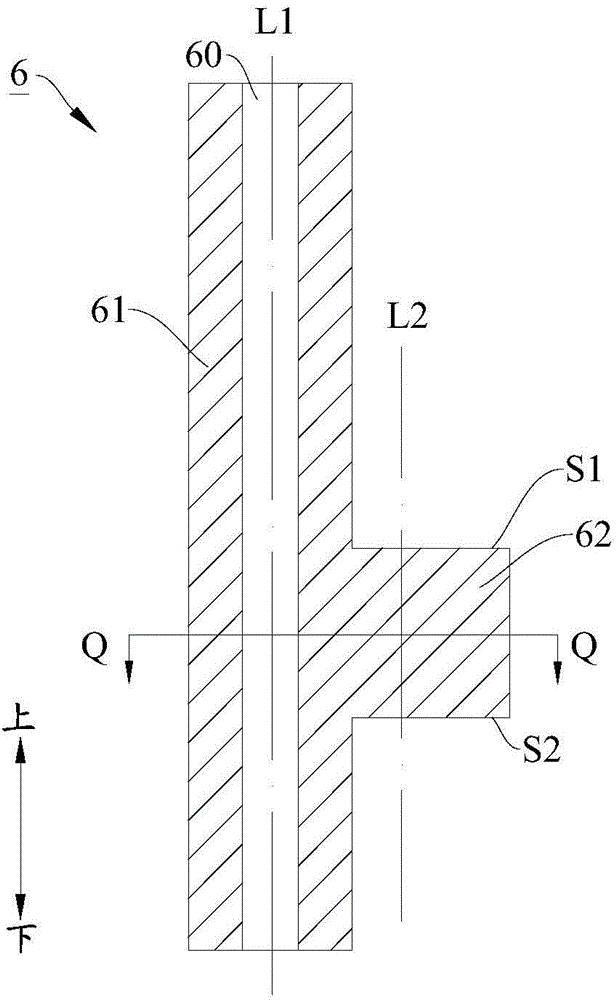

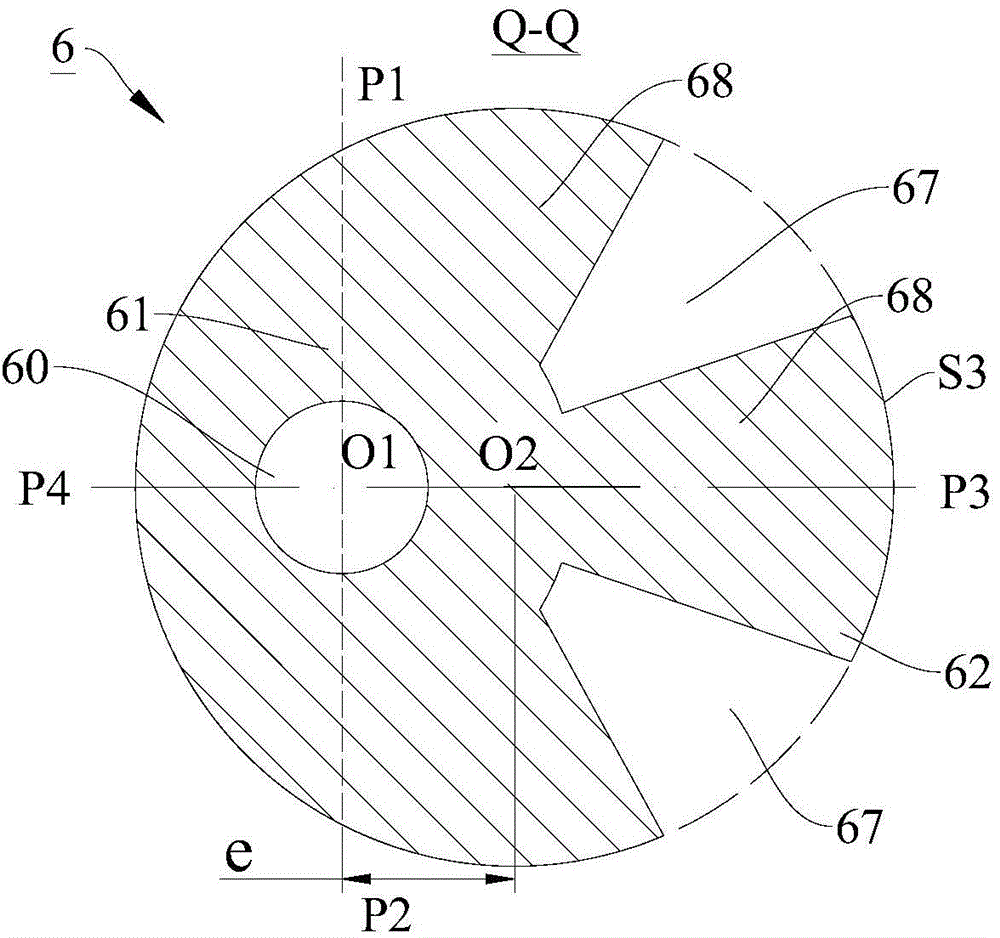

[0058] In this embodiment, as figure 2 with image 3 As shown, a plurality of protrusion structures 68 are provided on the outer peripheral surface of the main shaft portion 61, and two adjacent protrusion structures 68 define a first weight-reducing balance hole 67. That is, the crankshaft 6 cooperates with the piston 12 through a plurality of convex structures 68, or in other words, the outer peripheral surface S3 of the eccentric portion 62 is divided into a plurality of arc surfaces, and the plurality of arc surfaces contact and cooperate with the inner peripheral surface of the piston 12. In this way, the eccentric mass of the eccentric portion 62 is minimized, the rotational eccentric inertia force of the rotary compressor 100 using the crankshaft 6 is reduced, the vibration and noise of the compressor are reduced, and the internal balance of the compressor is also reduced. Weight of block 13.

[0059] In the first embodiment, by providing a plurality of first weight-reduc...

Embodiment 2

[0066] In this embodiment, as Figure 4 with Figure 5 As shown, the structure of the crankshaft 6 is substantially the same as the structure of the crankshaft 6 in the first embodiment, which will not be repeated here.

[0067] The difference is that in the second embodiment, at least one protruding structure 68 is provided with a second weight-reducing balance hole 69, so that the eccentric mass of the eccentric portion 62 can be further reduced, and the rotation of the crankshaft 6 can be reduced. The rotational eccentric inertia force of the compressor 100 reduces the vibration and noise of the compressor, and facilitates the reduction of the weight of the balance weight 13 in the compressor.

[0068] Specifically, the cross-sectional shape of the second weight-reducing balance hole 69 may be a square, a circle, a crescent shape, or a fan shape, and the cross-sectional shape of the second weight-reducing balance hole 69 may also be other shapes. There may be multiple second wei...

Embodiment 3

[0075] In this embodiment, as Figure 8 with Picture 9 As shown, the outer peripheral surface of the main shaft portion 61 is provided with a plurality of connecting plates 621, the free end of each connecting plate 621 is provided with an arc-shaped plate 622, and two adjacent connecting plates 621 define a first weight-reducing balance hole. 67. That is to say, the crankshaft 6 is matched with the piston 12 through a plurality of arc-shaped plates 622, or in other words, the outer peripheral surface S3 of the eccentric portion 62 is divided into a plurality of arc surfaces, and the plurality of arc surfaces are connected to the inner circumference of the piston 12. In this way, the eccentric mass of the eccentric portion 62 can also be minimized, so as to reduce the rotational eccentric inertia force of the rotary compressor 100 using the crankshaft 6, and reduce the vibration and noise of the compressor, which is also convenient This reduces the weight of the balance block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com