Crankshaft, compressor and air conditioner

A technology for compressors and air conditioners, applied in the field of compressors, can solve problems such as the overall performance decline of the compressor, the reduction of compressor efficiency, and the aggravation of crankshaft wear and vibration, so as to ensure overall performance, reduce quality, and avoid wear and vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

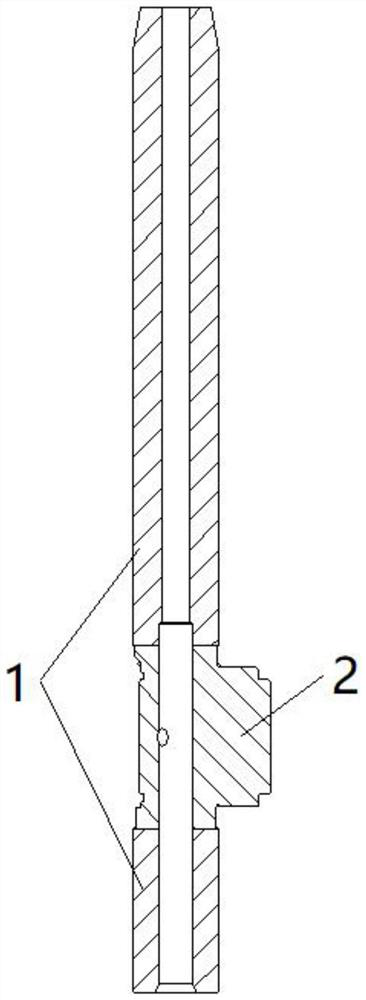

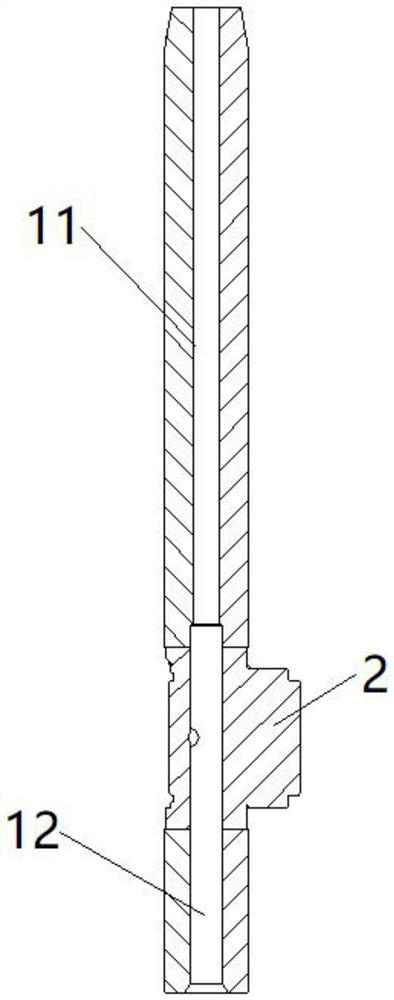

[0029] This embodiment provides a crankshaft, such as figure 1 The crankshaft shown includes a crankshaft body 1 and an eccentric portion arranged on the crankshaft body 1, the eccentric portion 2 is made of a first material, the crankshaft body 1 is made of a second material, and the density of the first material is smaller than that of the second material , used to reduce the mass of the eccentric part 2.

[0030] The eccentric part 2 of the crankshaft is made of the first material, and the crankshaft body 1 is made of the second material, and the density of the first material is smaller than that of the second material, so that the mass of the eccentric part 2 of the crankshaft is reduced, thereby making the rotation of the crankshaft The eccentric inertial forces, ie the centrifugal force, are reduced; in this way wear and vibrations due to deflection effects are avoided.

[0031] Moreover, compared with the traditional method of reducing the eccentric mass of the cranksh...

Embodiment 2

[0056] This embodiment provides a compressor, and the compressor includes the crankshaft of Embodiment 1.

Embodiment 3

[0058] This embodiment provides an air conditioner, and the air conditioner includes the compressor of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com