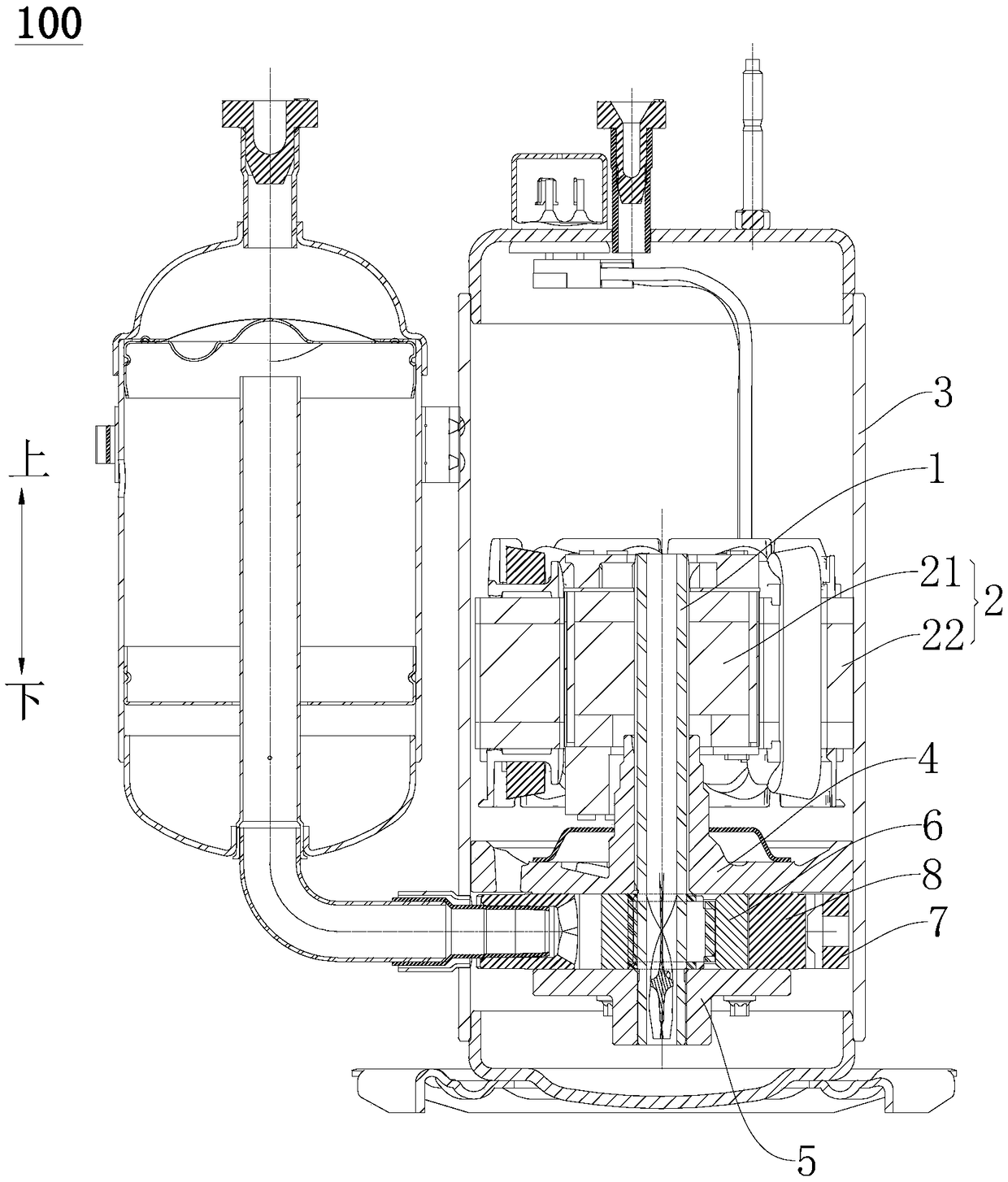

Crankshaft for compressor and compressor having same

A compressor and crankshaft technology, applied in the field of compressors, can solve the problems of reducing the reliability of the compressor, unfavorable performance of the compressor, increasing the centrifugal inertial force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

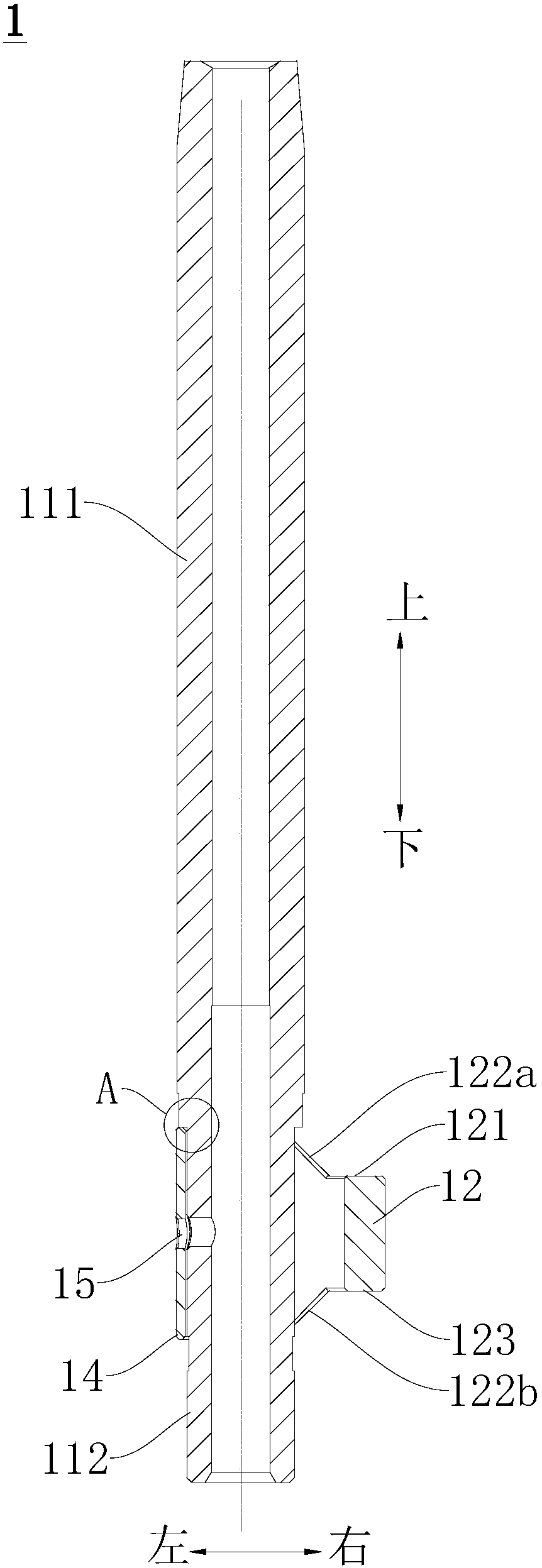

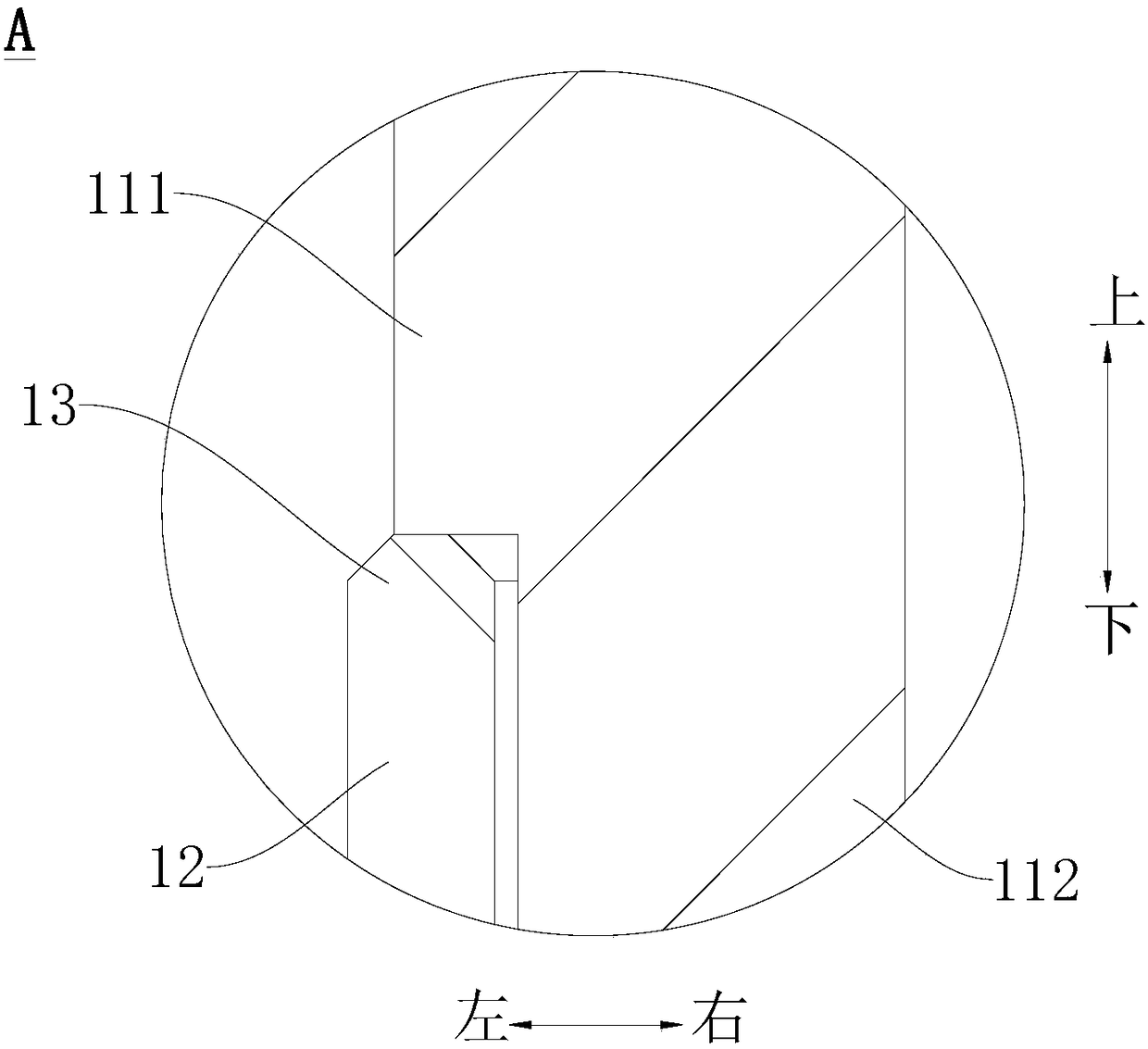

[0047] refer to Figure 2-Figure 5 , in this example, refer to figure 2 and Figure 4 , the crankshaft 1 includes a first pipe body 11 and a second pipe body 12 , and an upper thrust portion 13 protruding upward is integrally formed on the upper end of the second pipe body 12 . Wherein, the first pipe body 11 includes a first section 111 and an end provided at the first section 111 (refer to figure 2 and Figure 4 The second section 112 of the lower end of the first section 111), the outer diameter of the second section 112 is smaller than the outer diameter of the first section 111, and the second pipe body 12 is sheathed on the outer peripheral wall of the second section 112. Thus, the weight of the crankshaft 1 can be further reduced, materials can be saved, and costs can be reduced. What needs to be explained here is that the lower part of the second section 112 of the first pipe body 11 is matched with the auxiliary bearing 5 of the compressor 100, and the outer dia...

Embodiment 2

[0062] refer to Figure 6-Figure 9 , the difference between the crankshaft 1 in this embodiment and the first embodiment above lies in the structure of the second pipe body 12 . Other structures of the crankshaft 1 in this embodiment are substantially the same as those in the first embodiment above, and will not be repeated here. In addition, it should be noted that the same reference numerals are used for the same components in this embodiment as in the first embodiment.

[0063] In this example, refer to Figure 6 and Figure 9 The upper end surface 121 of the second pipe body 12 is a slope inclined downward from the upper surface of the upper thrust portion 13, and the slope extends from the edge of the upper thrust portion 13 downward and obliquely to the right to the bottom of the second pipe body 12. outer edge. Thus, the weight of the second pipe body 12 can be further reduced, that is, the weight of the eccentric portion of the crankshaft 1 can be reduced, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com