Ball valve

A technology of ball valves and valve seats, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of reduced sealing performance, shortened service life, and non-replacement of valves, so as to improve the sealing performance and service life. Effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

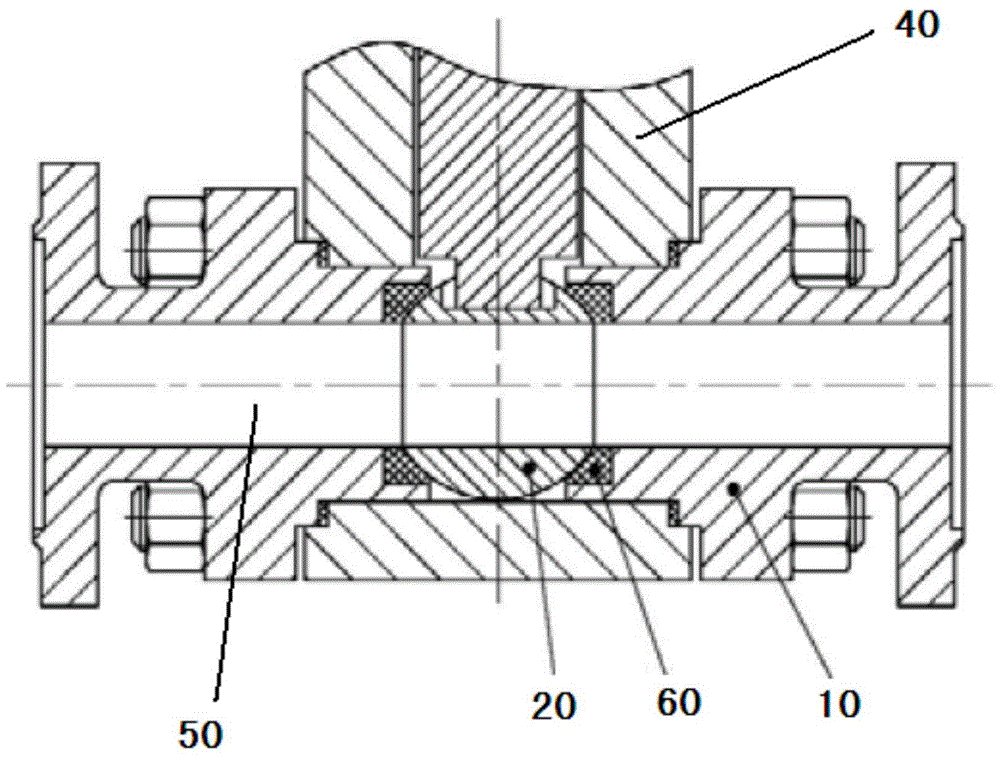

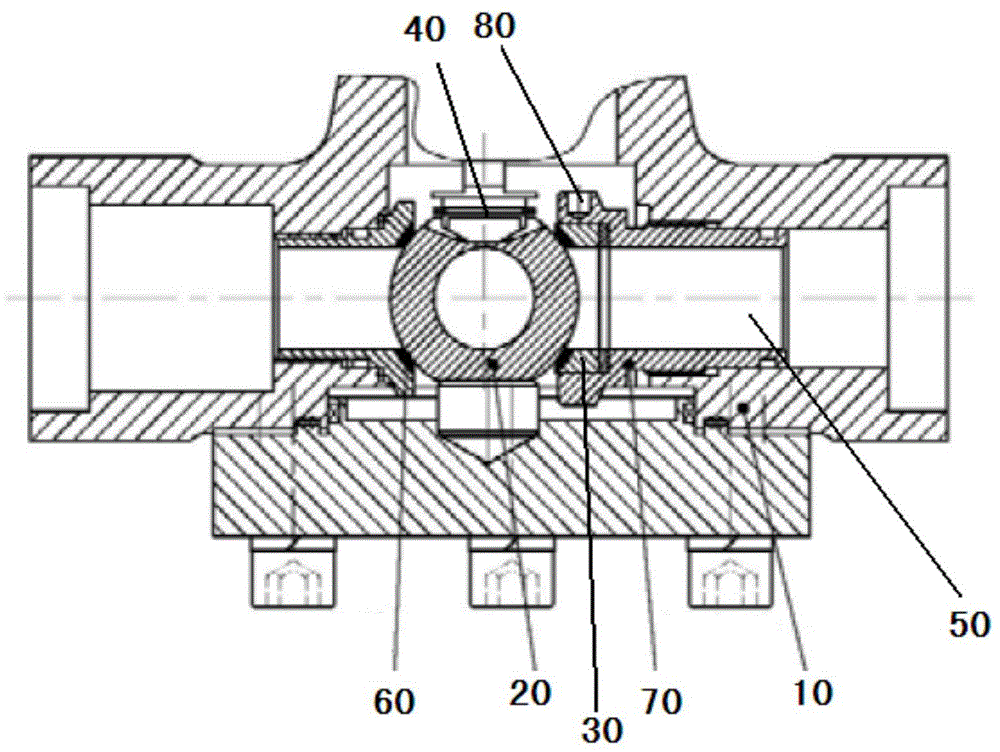

[0018] see figure 2 As shown, the present invention discloses a ball valve, comprising a valve body 10, a ball 20, a valve seat 30, a valve stem 40 and a handle, the valve stem 40 is connected to the ball 20, and the handle is used to drive the valve stem 40 to rotate; the valve body 10 A fluid through hole 50 is provided between the inlet and the outlet, and the ball 20 is arranged at the interruption of the fluid through hole 50 of the valve body, and the ball 20 rotates around the axis of the valve stem within a quarter of a circle between the closed state and the open state; the valve The body 10 is a one-time molding structure, which ensures the mechanical properties of the body material.

[0019] There is generally a gap between the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com