hose coupling

A connector and hose technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of reducing the rupture resistance, the hose tube is not tight, and achieve the effect of high sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

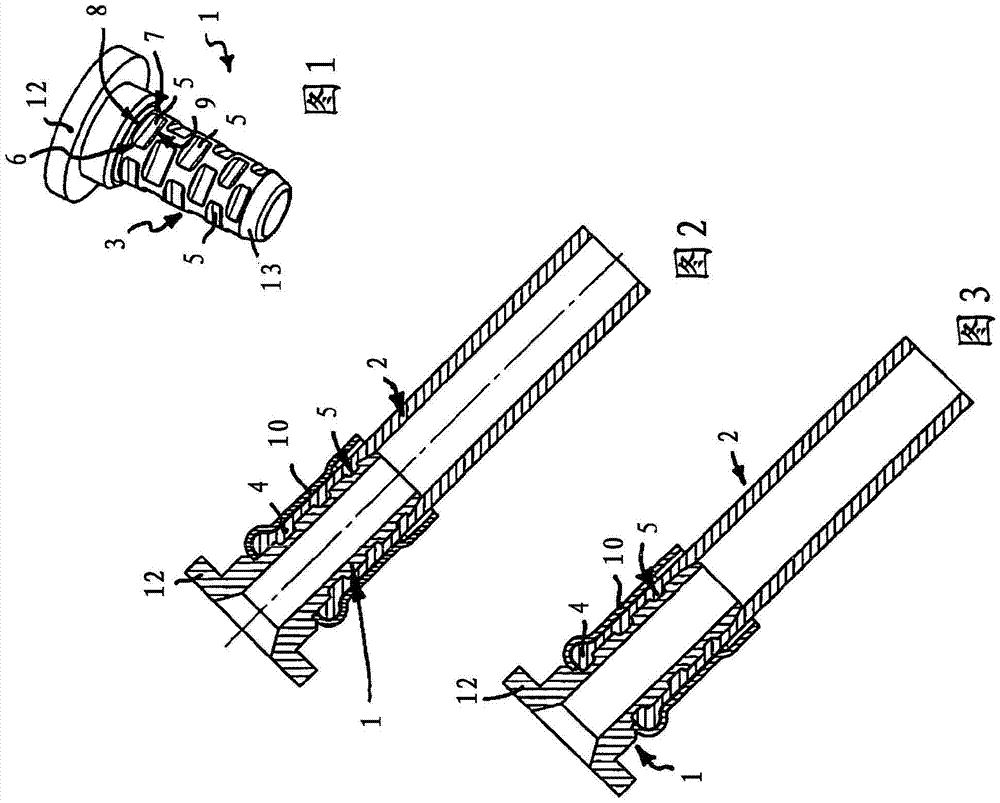

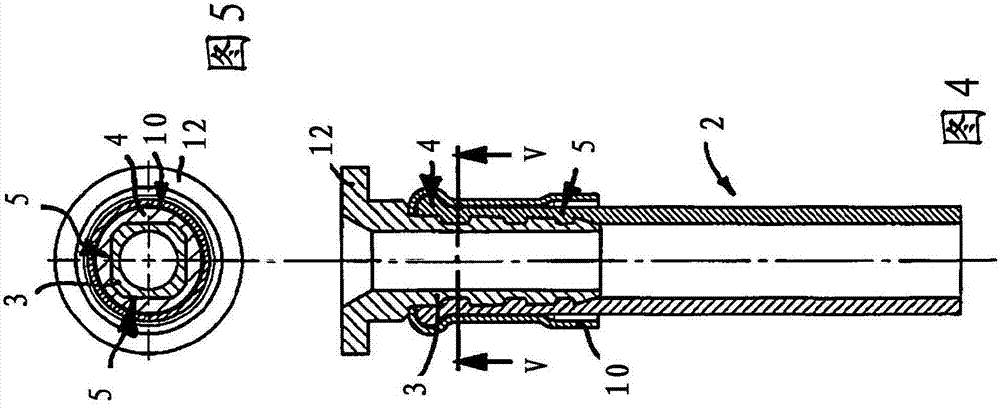

[0035] exist Figures 1 to 5 A hose coupling 1 is shown in , which is used to connect a flexible hose 2 , for example, to a stop valve or to a sanitary outlet fitting or similar water consumption point. The sleeve-shaped hose coupling 1 has, on at least one coupling end, a connecting piece 3 which has a retaining profile on the outer circumference at least in the region of the socket part.

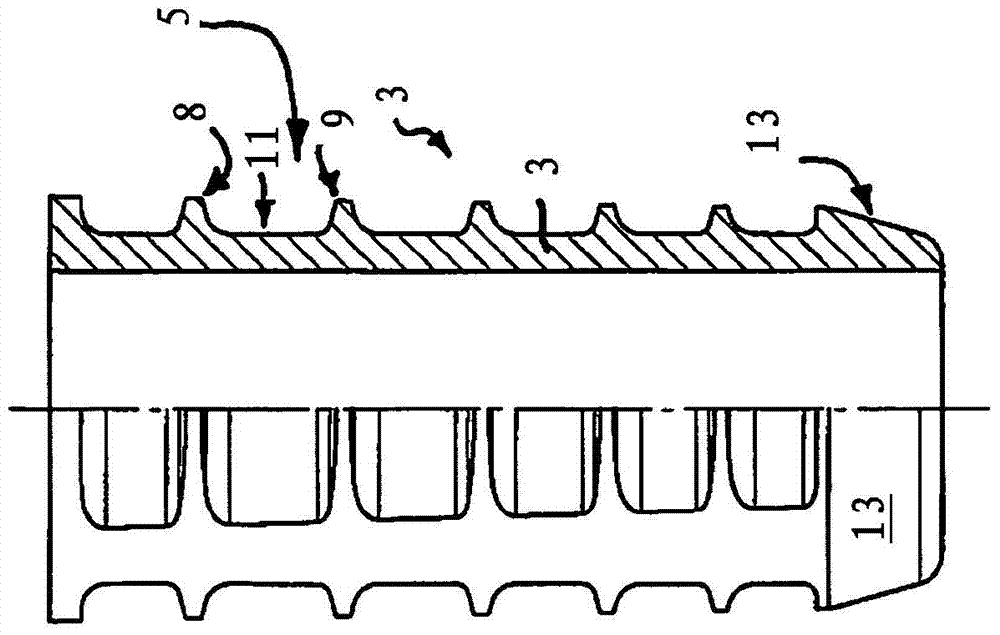

[0036] as in Figures 2 to 5 As can be seen in , the hose end 4 of the flexible hose 2 can be pushed onto the at least one formed coupling end. The retaining profile provided on the connecting pipe 3 of the hose coupling 1 is formed by at least one and preferably—as here—by a plurality of retaining grooves 5 arranged on the outer circumference of the connecting pipe 3 . Each of these retaining grooves 5 formed as recesses into the outer circumference of the socket has narrow groove sides 6 , 7 oriented in the longitudinal direction of the socket and long groove sides 8 , 9 oriented in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com