A cement preheater hanger and its installation method

A cement preheater and hanger technology, which is applied in the directions of preheating costs, supporting machines, lighting and heating equipment, etc., can solve the problems of unstable fixing method of hanging pieces, complicated installation and danger, and achieve a simple, safe and reliable structure. , Solve the effect of poor installation efficiency and increase safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

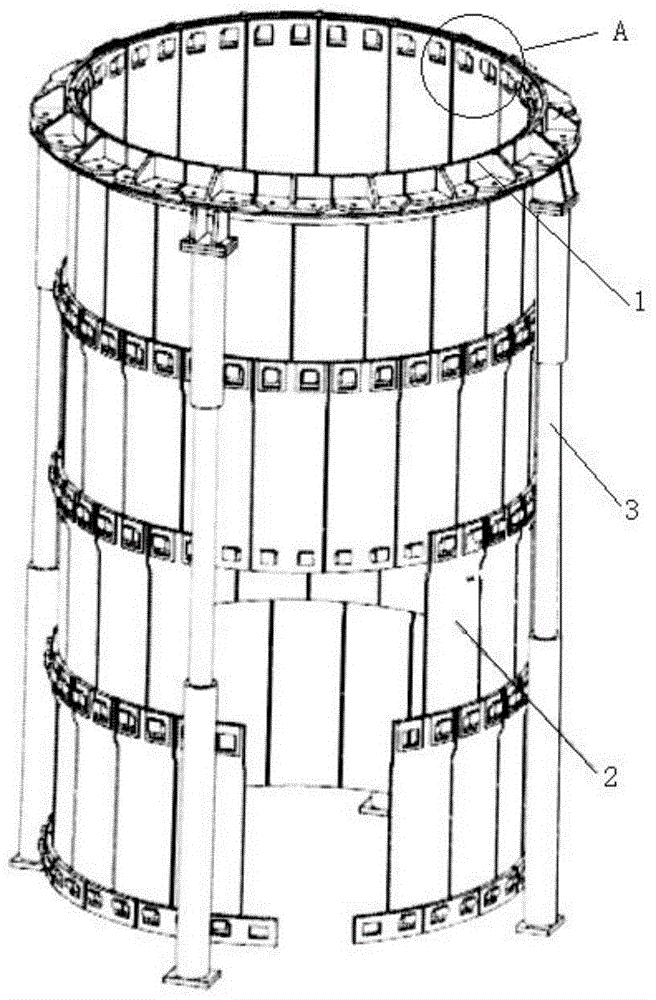

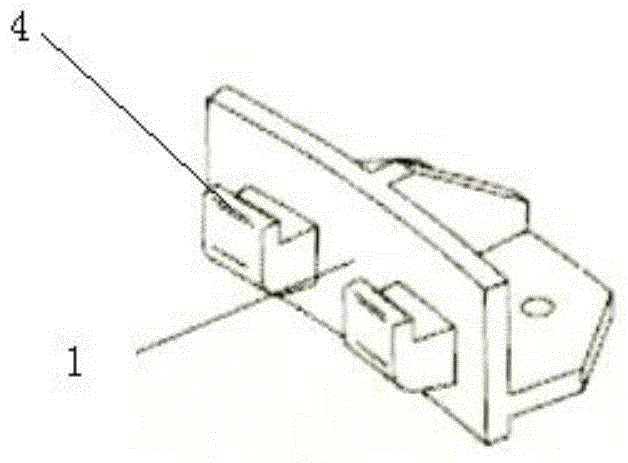

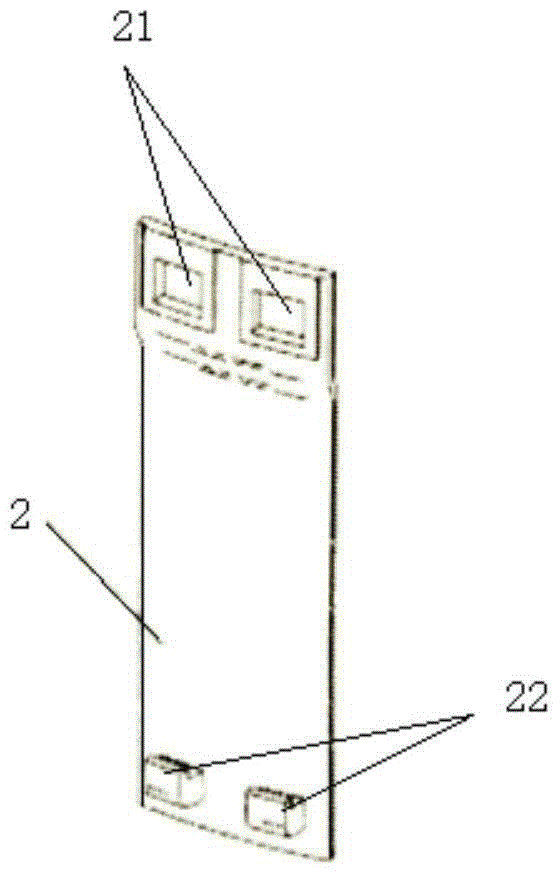

[0026] The cement preheater hanger provided in this embodiment is mainly composed of hanging pieces, ring beams and four support rods, see figure 1 . The support rod is telescopically supported on the peripheral side of the ring beam, and the hanging pieces are closely arranged under the ring beam layer by layer. The hanging pieces of each layer are connected in a staggered manner. The first connecting piece and the second connecting piece matched with each other are provided respectively, and the ring beam is connected with the first connecting piece through the fixed connecting piece to realize the connection between the ring beam and the first hanging piece close to the ring beam, and the hanging piece passes through the hanging piece on the hanging piece. The second connecting piece is correspondingly connected with the first connecting piece of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com