Fuse mounting structure

An installation structure and fuse technology, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of low fuse fixing reliability, difficulty in installing fuses, short-circuiting of fuses, etc., so as to avoid short-circuit faults, improve protection and fix The effect is flexible and not easy to short-circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

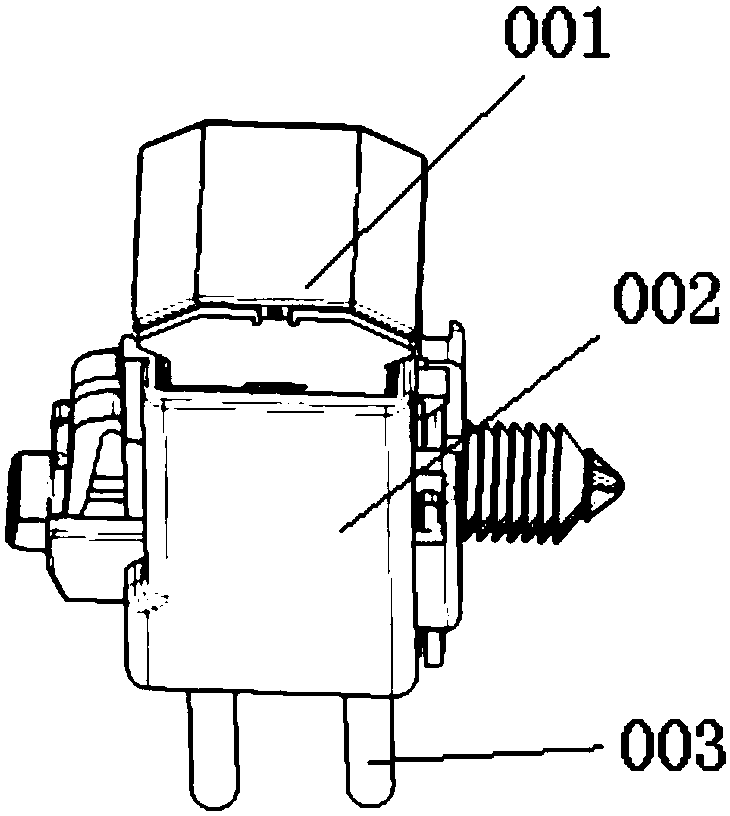

[0059] The present invention provides a fuse installation structure, such as figure 1 As shown, it includes a fuse assembly 001, a fuse base 002 and a wire harness terminal 003; the wire harness terminal 003 is fixed on the fuse base 002; when the fuse assembly 001 is inserted into the fuse base 002, the wire harness terminal 003 into the fuse assembly 001.

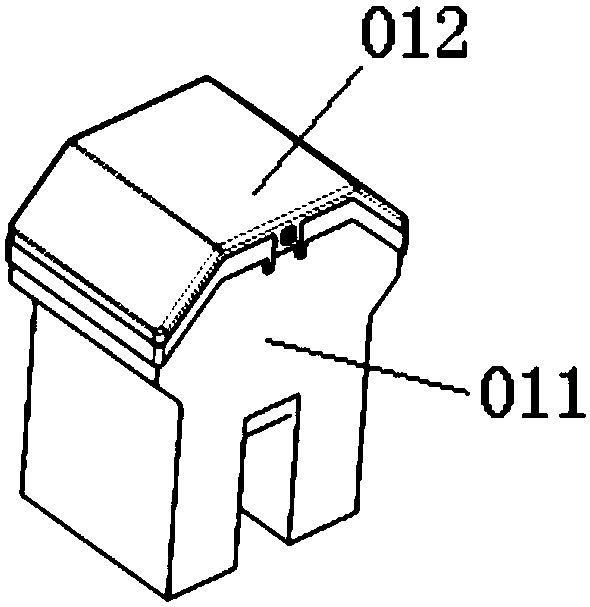

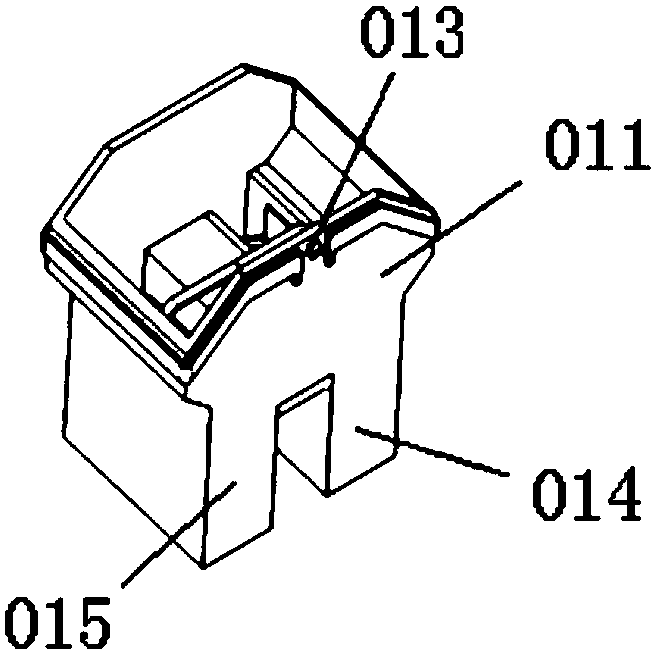

[0060] like Figure 2 to Figure 11 ,and Figure 13 and Figure 16 As shown, the fuse assembly 001 includes a fuse case and a fuse; the fuse is clipped into the fuse case.

[0061] The fuse case includes a case body 011, a case cover 012, a left pin part 014 and a right pin part 015; the upper end of the case body is a two-sided inclined structure, that is, the left pin part and the right pin part are connected at the same time The upper ends of the two sides of the housing are all inclined structures with a high middle and low sides, and the shell cover structure is matched with the structure of the upper end of the s...

Embodiment 2

[0091] The present invention provides a fuse installation structure, such as figure 1 As shown, it includes a fuse assembly 001, a fuse base 002 and a harness terminal 003; the harness terminal is fixed on the fuse base; when the fuse assembly is inserted into the fuse base, the harness terminal is inserted into the fuse Assembly.

[0092] like Figure 2 to Figure 12 ,and Figure 14 to Figure 16 As shown, the fuse assembly includes a fuse case and a fuse; the fuse is clipped into the fuse case.

[0093]The fuse case includes a case body 011, a case cover 012, a left pin part 014 and a right pin part 015; the upper end of the case body is a two-sided inclined structure, that is, the left pin part and the right pin part are connected at the same time The upper ends of the two sides of the housing are all inclined structures with a high middle and low sides, and the shell cover structure is matched with the structure of the upper end of the shell body; the shell cover is clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com