Out-box molten aluminum heating device

A heating device and aluminum liquid technology, applied in the field of aluminum melt, can solve the problems of slow heating method, heating temperature not meeting requirements, long heating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

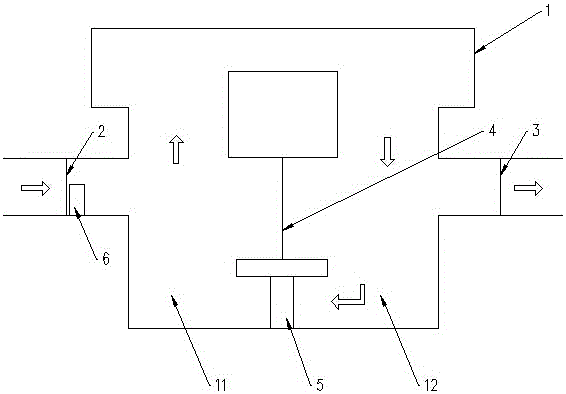

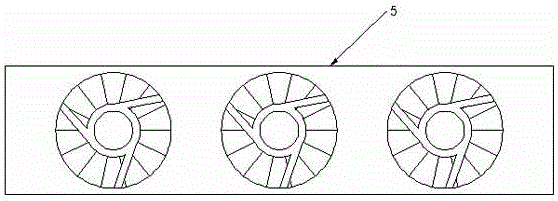

[0016] Such as Figure 1-2 As shown, the aluminum liquid heating device outside the box provided by this embodiment includes a vacuum degassing box 1. The two sides of the vacuum degassing box 1 are respectively provided with an aluminum liquid inlet and an aluminum liquid outlet. Closed ram 2, the outlet of the aluminum liquid is provided with an outlet fully-closed ram 3; the chamber of the vacuum degassing box 1 is provided with a middle semi-closed ram 4, which divides the chamber into two left and right chambers A 11 and B In the chamber 12, there is a gap between the bottom of the middle semi-closed gate 4 and the bottom of the vacuum degassing box 1, and an electromagnetic stirrer 5 is provided at the gap; a heater 6 is provided at the inlet of the molten aluminum.

[0017] The inlet fully enclosed ram 2 , the outlet fully enclosed ram 3 and the middle semi-close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com