Hydraulic actuator and compound rocker arm

A technology of hydraulic actuation and hydraulic oil, applied in the direction of fluid pressure actuation device, transmission device, fluid transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

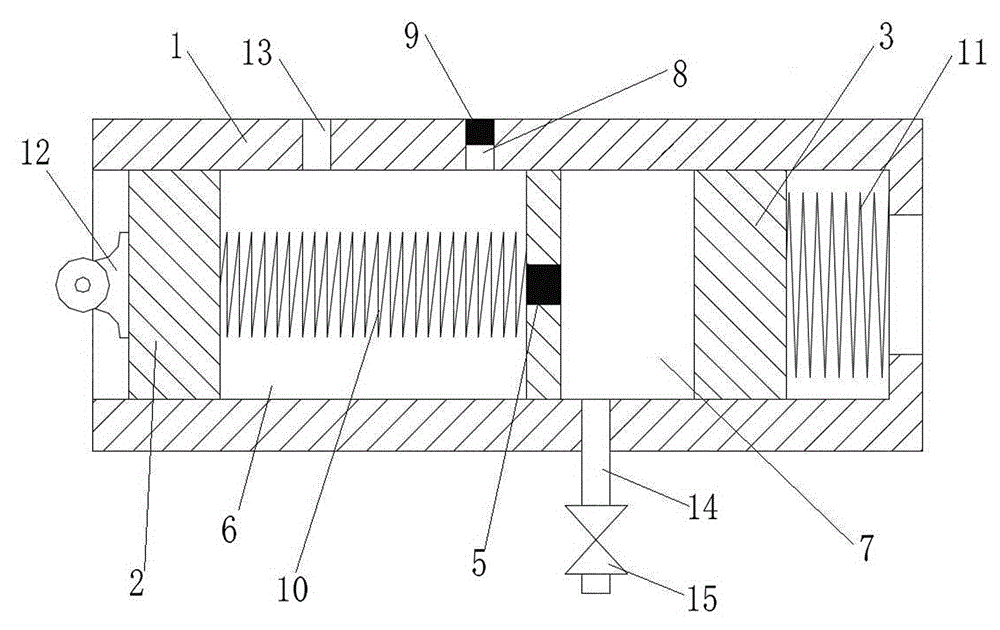

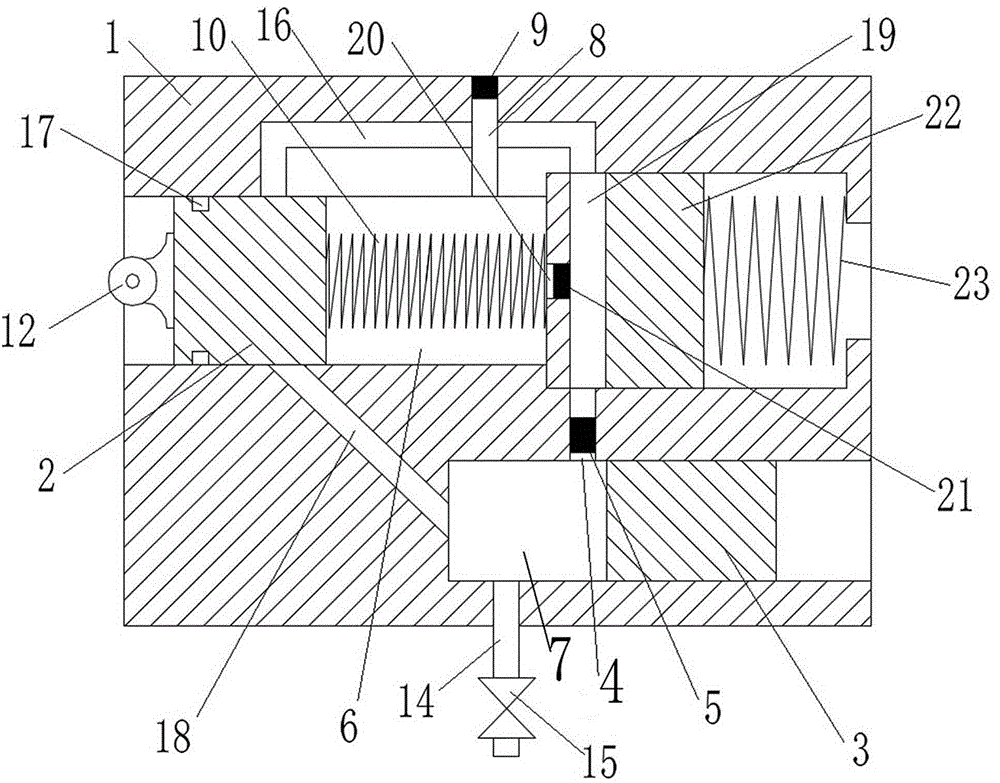

[0025] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0026] A hydraulic actuator, comprising: a housing 1, which is divided into two mutually independent chambers I 6 and chamber II 7, and the chamber I 6 and chamber II 7 are communicated through the oil delivery channel I 4 ;Input piston 2, which is slidably installed in cavity I 6; output piston 3, which is slidably installed in cavity II 7, oil inlet 8, which is arranged on cavity I 6, and communicated with cavity I 6 , the input piston 2 will not close the oil inlet 8 during the sliding stroke in the chamber I 6; the oil return port 14, which is arranged on the chamber I 6, communicates with the chamber II 7, and the oil return port 14 There is a control valve 15 on the top, the output piston 3 will not close the oil return port 14 during the sliding stroke of the cavity II 7; and a delay mechanism, the delay mechanism makes the input piston 2 after a certain delay during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com