Single-flow double-metering liquefied natural gas filling machine

A technology of liquefied natural gas and gas filling machine, which is applied to mechanical equipment, container discharge method, equipment loaded into pressure vessels, etc., can solve problems such as cheating, achieve reasonable internal structure, satisfactory measurement accuracy, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

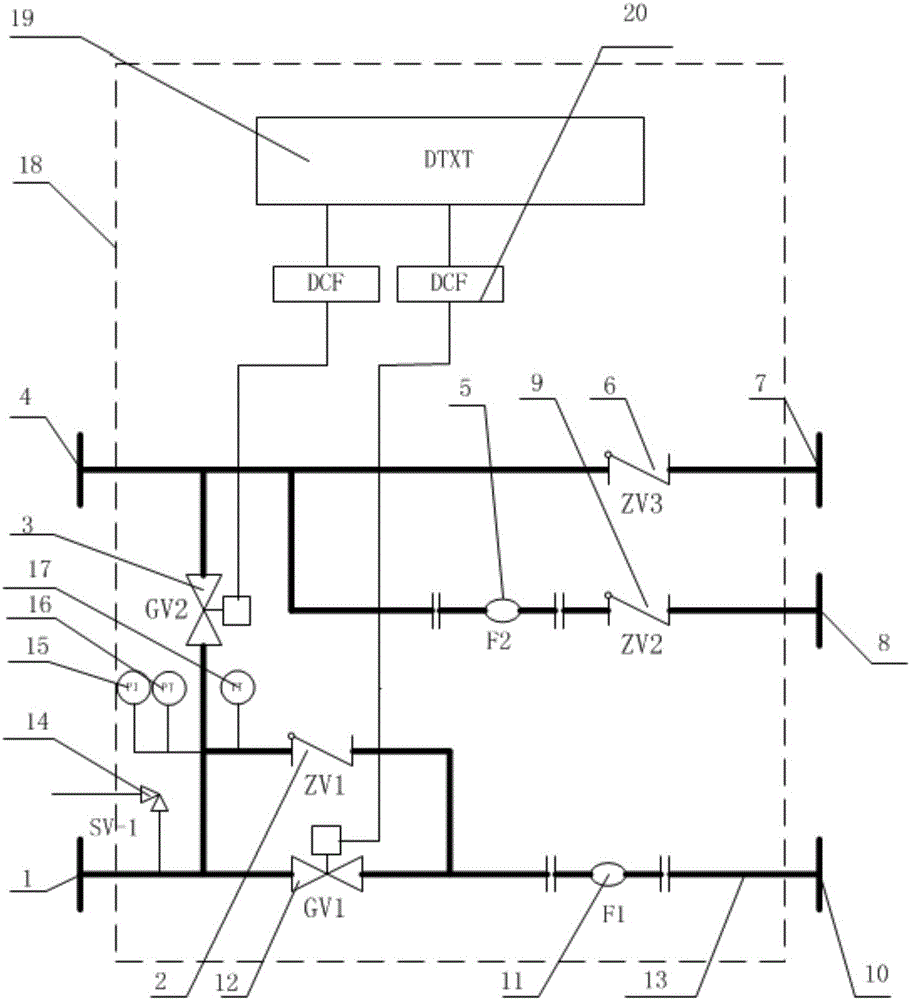

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] see figure 1 , a single-flow double-metering LNG dispenser, comprising a casing 18, and the casing 18 is provided with a return line, a return gas line, a circulating pre-cooling line and a filling line; the filling line includes a through pipe The pipeline system 13 is connected to the gas machine liquid inlet 1, the pneumatic emergency cut-off ball valve 12, the mass flow meter 11 and the liquid filling gun 10 in sequence, and the return line is connected to the gas machine liquid inlet 1 and the pneumatic emergency cut off through the circulating precooling pipeline. Between the ball valves 12, the return line is connected with a return air line. One end of the check valve 2 is connected with the circulating pre-cooling line through the temperature sensor 17, and the other end is connected between the pneumatic emergency cut-off ball valve 12 and the mass fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com