Full-automatic film-laying soil-covering transplanter

A transplanting machine, fully automatic technology, applied in transplanting machinery, planting methods, excavation/covering trenches, etc., can solve the problems of ditching discs puncturing the mulch, poor adaptability, unfavorable work efficiency, etc. Versatility and adaptability, avoiding insufficient soil cover and easy dumping, accurate and reliable effect of transplanting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

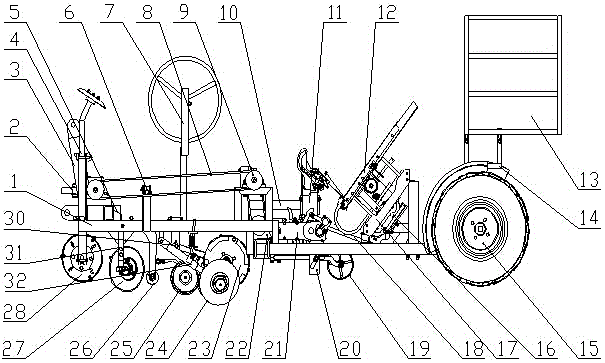

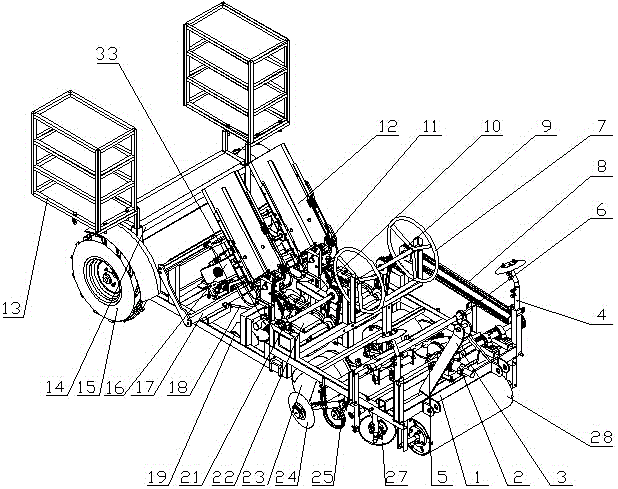

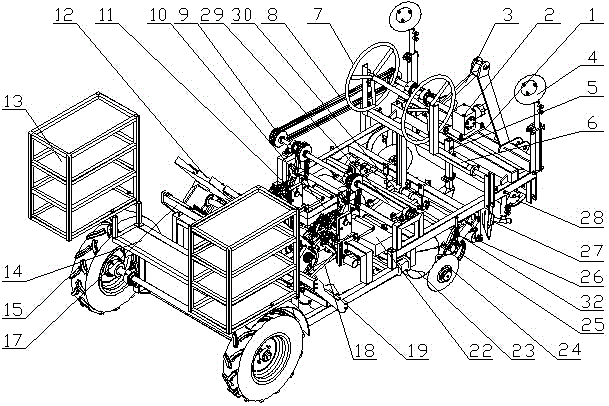

[0028] With reference to accompanying drawing, a kind of full-automatic film-laying soil-covering transplanting machine comprises frame, transmission mechanism, film-laying mechanism, drip irrigation belt laying mechanism, ditching film-laying soil-covering mechanism, transplanting mechanism and walking wheel 15, is characterized in that transmission Mechanism, ditching film covering soil mechanism, drip irrigation belt laying mechanism, transplanting mechanism are respectively located on the frame, and the walking wheel 15 is located at the rear side of the frame; the frame includes the transplanting machine frame 1, Three-point suspension 3, get seedling installation support 10, seedling-carrying frame 13 and seat support 14, above-mentioned three-point suspension 3 is located at the front side of transplanting machine frame 1, links to each other with traction tractor, gets seedling installation support 10 to set In the middle part of the transplanter frame 1, it is used to ...

Embodiment 2

[0030] The difference between this example and Embodiment 1 is that the track markers 4 on both sides of the transplanter are put down when the transplanter is working, and are used to mark the walking track of the transplanter. When carrying out the operation of turning around and changing lines in the field, it can walk along the track marked by the track marker 4 to ensure the operation width, and the operation width of this machine is 0.94 meters.

Embodiment 3

[0032] The difference between this example and Embodiment 1 is that there is an adjustment block on the lower side of the planting mechanism 21. If the depth of planting seedlings is too deep or too shallow, the adjustment block of the planting mechanism 21 can be adjusted to keep the planting at a reasonable level. depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com