Lithium niobate wafer grinding device and grinding method with grinding pressure adjustment device

A grinding pressure and adjusting device technology, which is applied in the direction of grinding devices, grinding machine tools, working carriers, etc., can solve the problems of inability to adjust the pressure accurately, unsatisfactory, uneven grinding of the end face of the optical fiber, etc., and achieve intuitive and reliable adjustment and excellent grinding quality. equal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

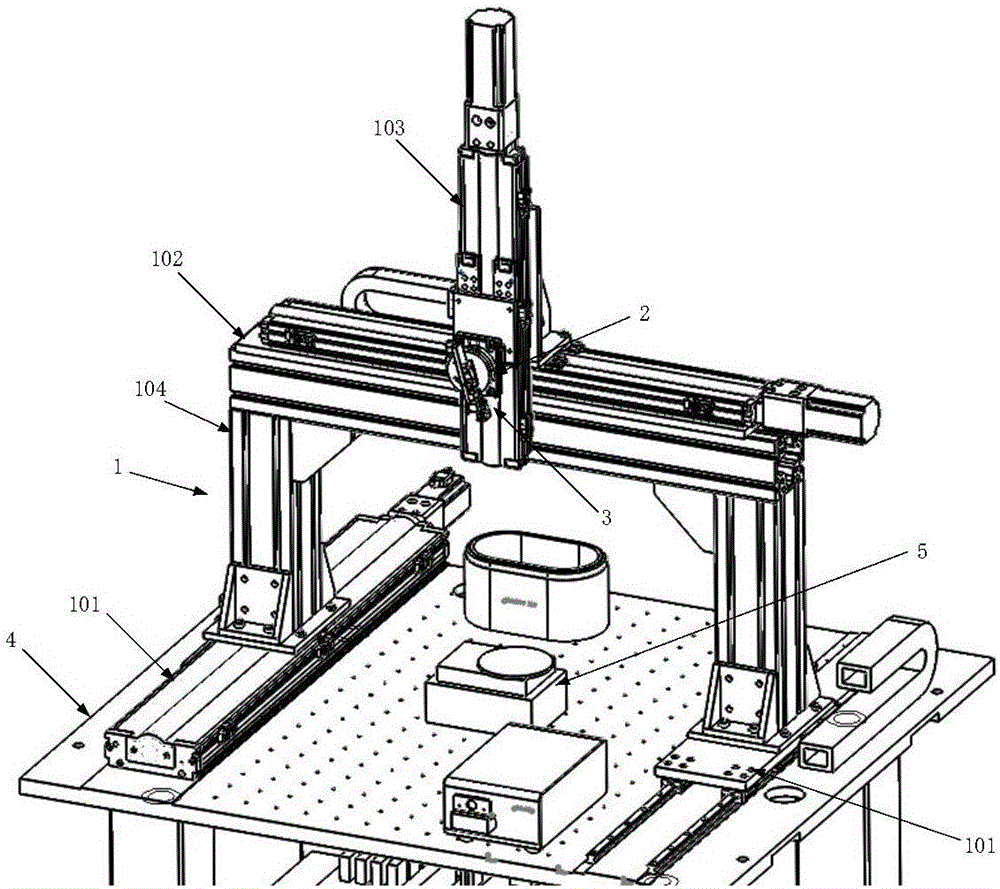

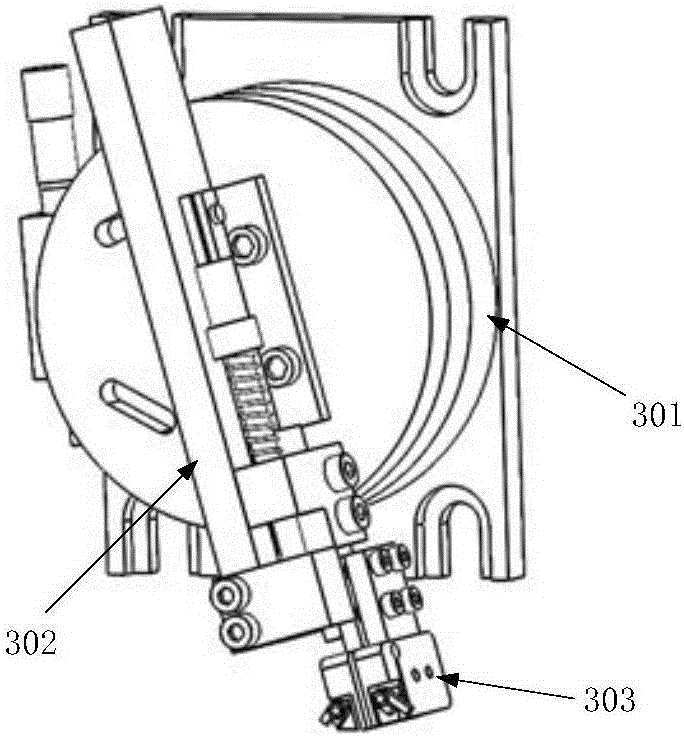

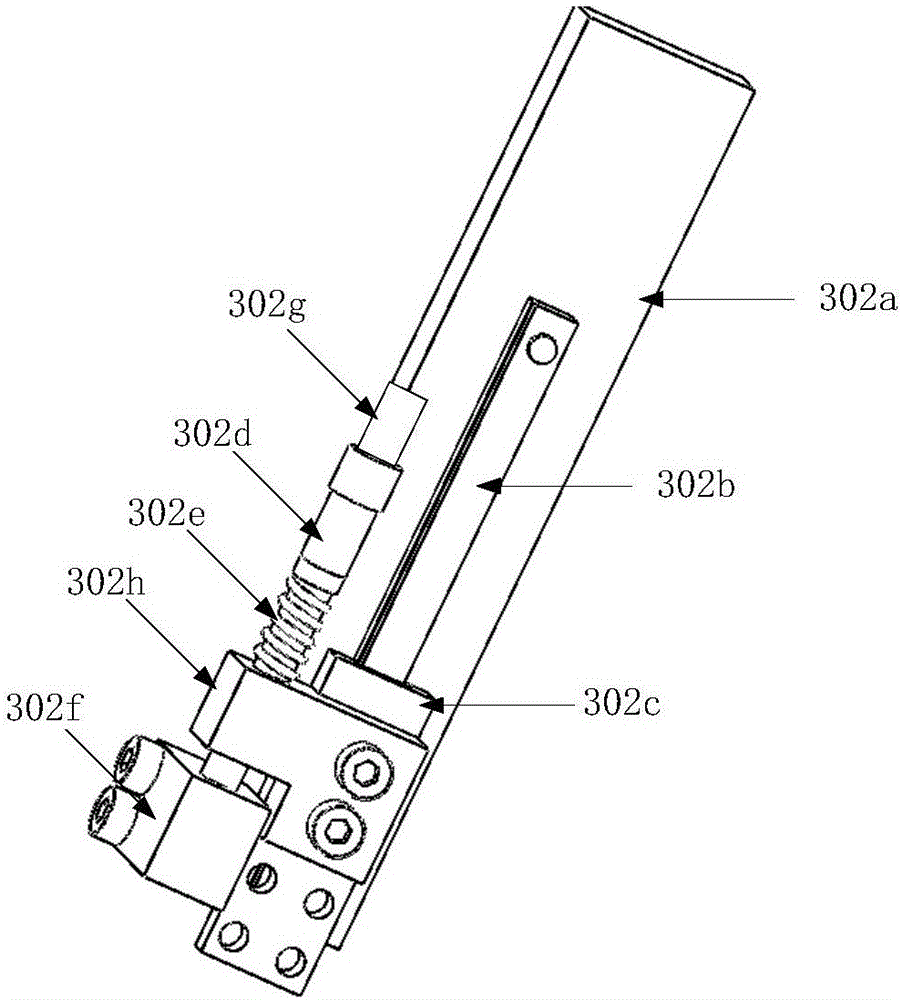

[0057] The present invention has the lithium niobate wafer grinding device of grinding pressure adjustment device, as figure 1 As shown, it includes a three-dimensional space positioning device 1 , a beam force sensor 2 and a grinding and clamping mechanism 3 .

[0058] The three-dimensional spatial positioning device 1 is set on the grinding platform 4 and adopts a door-shaped design, including two sets of x-axis moving mechanisms 101 , one set of y-axis moving mechanisms 102 , one set of z-axis moving mechanisms 103 and two pillars 104 . The x-axis moving mechanism 101 and the y-axis moving mechanism 102 are structurally the same as the z-axis moving mechanism 103, and are composed of a mounting table, a slide rail, a slide table, a ball screw and a driving motor. Wherein, two slide rails parallel to each other are installed on the mounting table. The scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com