column container

A technology of containers and combined columns, which is applied in the field of new containers, can solve the problems of inconsistent length, heavy column weight, long working time, etc., and achieve the effects of short working time, reliable connection and neat stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

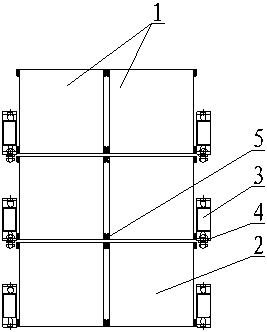

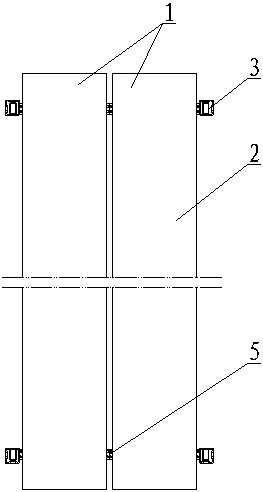

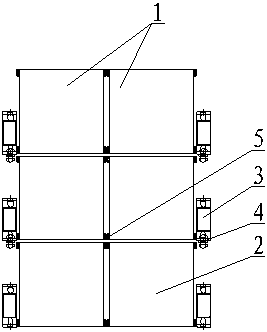

[0012] Such as figure 1 , figure 2 As shown, a column 2 container is composed of one or more layers of combined columns 1 . Each layer of combined columns 1 is composed of columns 2 connected side by side. The columns 2 connected side by side can be two or more columns 2 side by side. connect. The column 2 of the present invention can be a steel structure column 2 of various shapes, or a concrete column 2 , or a steel-concrete structure column 2 .

[0013] Four container corner fittings 3 are provided on the upper surface and the lower surface of each composite column 1, and the container corner fittings 3 may be installed by welding, riveting, clamping, bolting, mosaic connection, or plug-in connection. The installation positions of the four container corner fittings on each combined column comply with international general container standards. The surface of the container corner fitting 3 is flush with the upper surface of the composite column 1 of each layer, or lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com