Glass taking device

A technology of reclaiming device and glass, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of heavy weight, large glass size, time-consuming and laborious glass, etc., and achieve the effect of reducing impact and accurate position of reclaiming material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

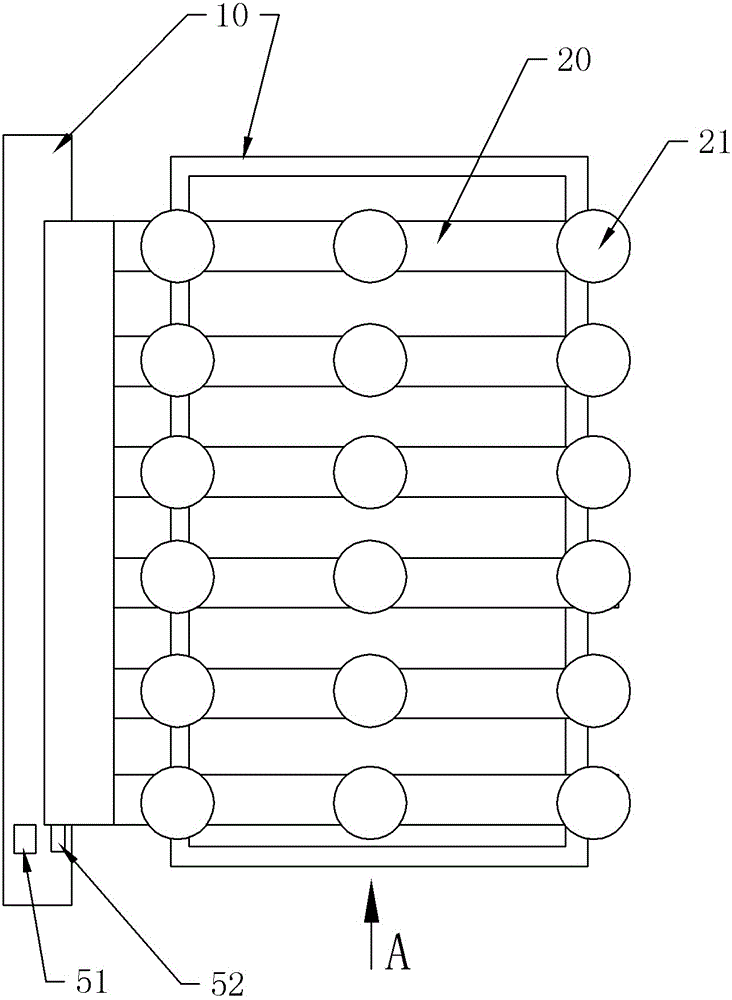

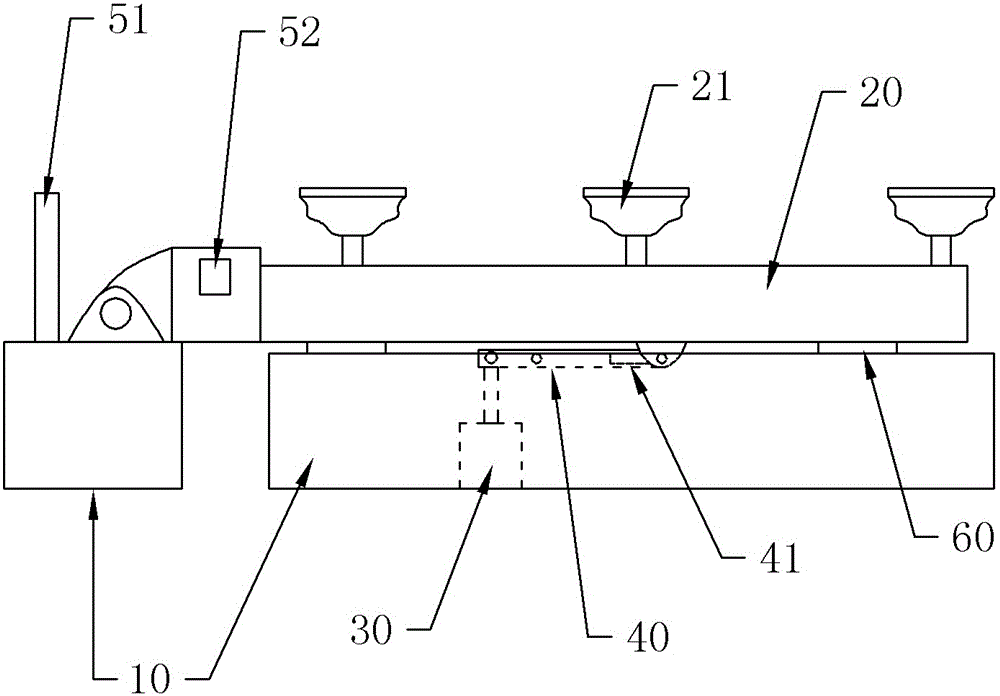

[0014] The reference numerals in the drawings of the description include: base 10, hydraulic cylinder 30, material retrieving frame 20, suction cup 21, buffer member 60, connecting rod 40, bar-shaped hole 41, bumper, travel switch 51, bumper 52.

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: a material retrieving device for glass, including a base 10 , an actuator, a material retrieving frame 20 , a suction cup 21 and a connecting rod 40 , and the actuator may be an air cylinder or a hydraulic cylinder 30 . The actuator in this embodiment selects the hydraulic cylinder 30 . The operation process of the hydraulic cylinder 30 is stable, and can provide relatively large stretching force. One side of the retrieving frame 20 is hinged with the base 10, and the retrieving frame 20 is provided with 30 suction cups 21 distributed in an array, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com