Transfer device for lithium battery production

A transfer device, lithium battery technology, applied in the direction of transportation and packaging, packaging, packaged item types, etc., can solve the problems of insufficient safety, damage to lithium batteries, unfavorable lithium battery production, etc., to achieve fast and convenient access and increase safety , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

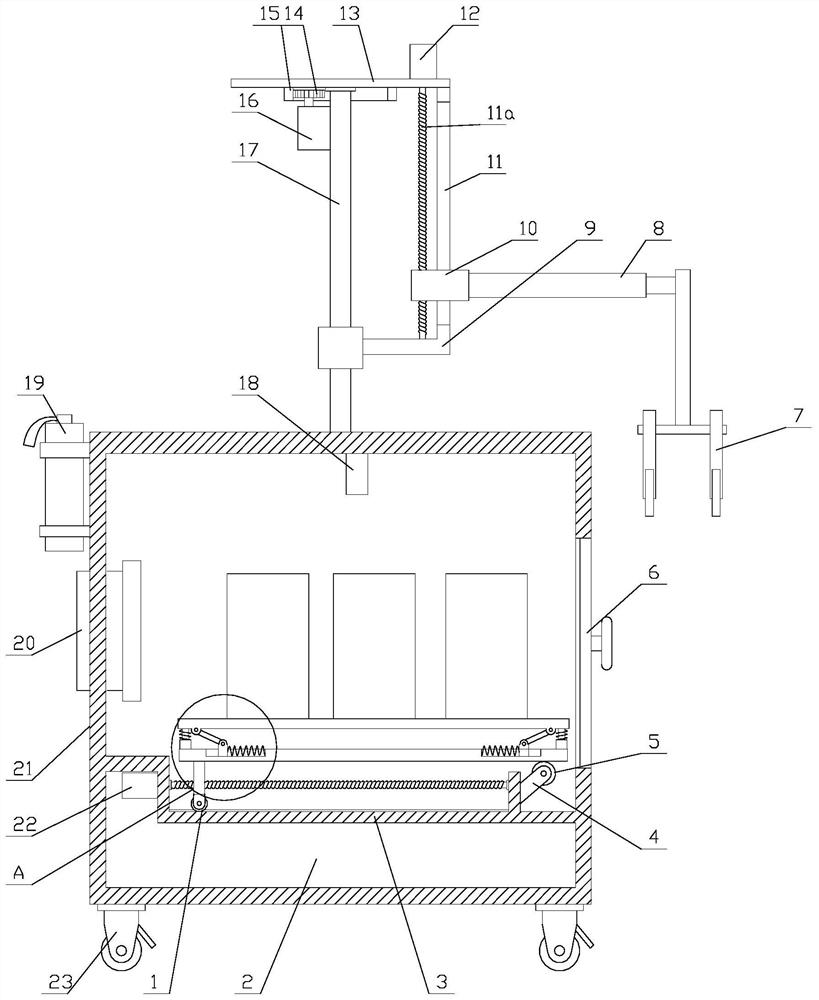

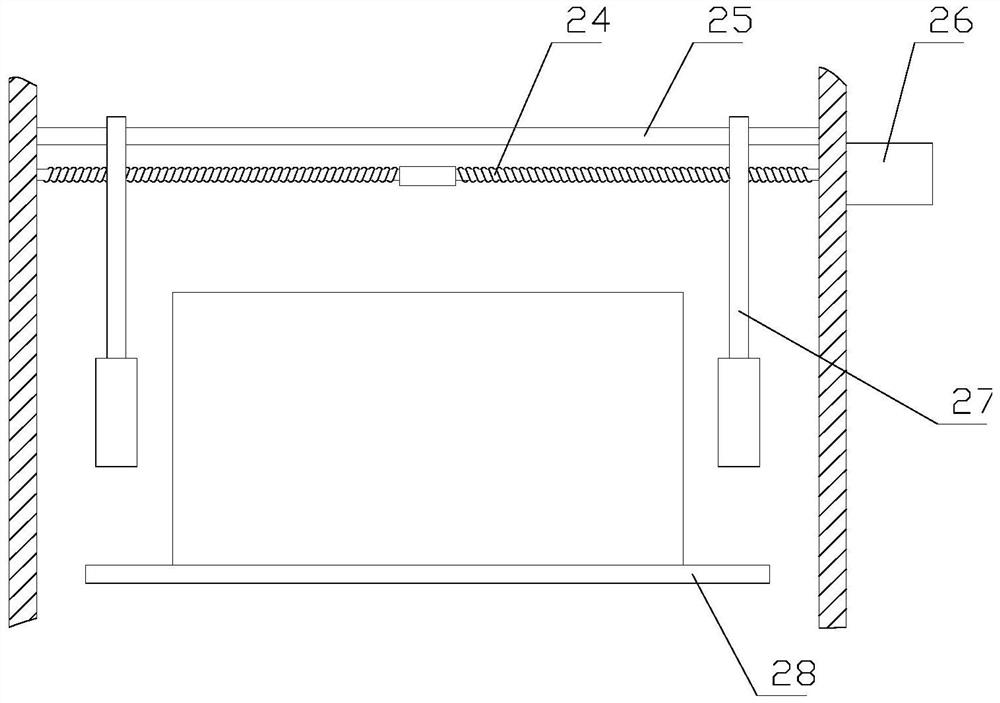

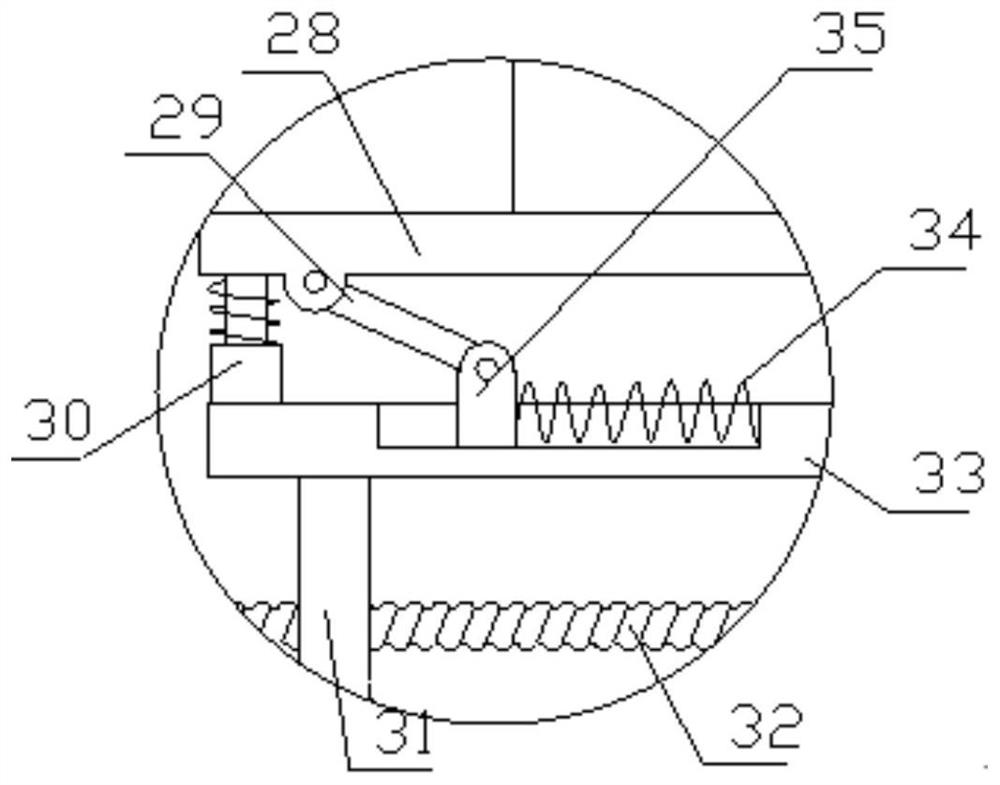

[0026] see figure 1 with Figure 3-5, a transfer device for lithium battery production, including a box 21, a thermostat 20, a temperature sensor 18, a fire extinguisher 19, an electric telescopic rod 8, a first motor 12, a second motor 16 and a third motor 22, the box The upper side of 21 is provided with a grabbing mechanism, and the grabbing mechanism includes a gripper 7, the upper end of the gripper 7 is fixedly connected to the electric telescopic rod 8, and the left side of the electric telescopic rod 8 is fixedly connected to the mobile support 10, and the mobile support 10 is threadedly connected with a first wire Rod 11a, the upper and lower sides of the first screw rod 11a are rotatably connected to the suspension 9, the lower side of the suspension 9 is rotatably connected to the center column 17, the upper side of the suspension 9 is fixedly connected to the rotating plate 13, and the center of the rotating plate 13 is rotatably connected to the center column 17. ...

Embodiment 2

[0029] see figure 1 The difference between this implementation and the above-mentioned embodiment 1 is that a fire extinguisher 19 is provided on the upper left side of the box body 21, which can reduce the loss of the lithium battery and increase the safety performance when the lithium battery catches fire.

[0030] The working principle of the present invention is: the lithium battery production transshipment device, when using the device for lithium battery production and transshipment, firstly, the lithium battery needs to be grasped into the box body 21, the box door 6 is opened, and then passed The gripper 7 grabs the lithium battery, adjusts the gripper 7 horizontally, left and right by controlling the electric telescopic rod 8, controls the first motor 12 to drive the first screw 11a to rotate, and controls the mobile bracket 10 to drive the gripper 7 to vertically To adjust the height, control the second motor 16 to make the gear 14 drive the inner gear ring 15 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com