Transferring tool of wooden door plate

A technology of transfer workers and wooden door panels, which is applied in the direction of manufacturing tools and workshop equipment, can solve the problems of simple structure, heavy weight, door body and door frame damage, etc., and achieve high transfer efficiency, simple and reasonable structure, and time-saving and labor-saving transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

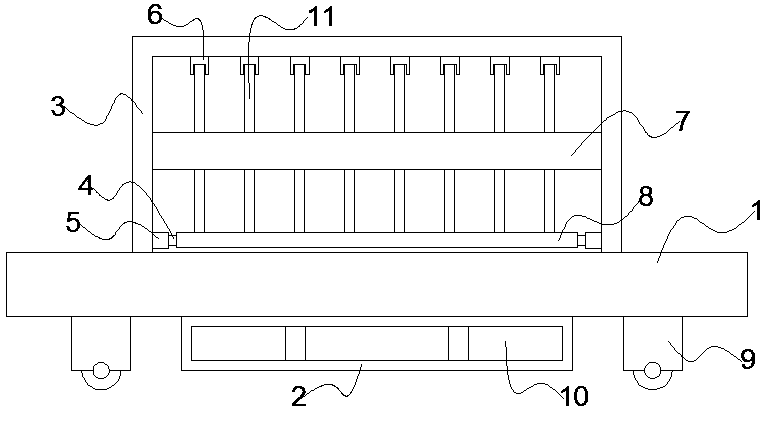

[0011] Such as figure 1 As shown, the present invention discloses a transfer tool for a wooden door panel, comprising: a transfer vehicle frame 1, a forklift frame 2, a U-shaped box 3, a rotating shaft 4, a rotating block 5, a U-shaped block 6, and a baffle plate 7. The bottom surface of the vehicle frame 1 is fixedly provided with a forklift frame 2, and the top surface of the transfer vehicle frame 1 is fixedly installed with an upside-down U-shaped box 3, and the top plate of the U-shaped box 3 is equidistantly installed with Several U-shaped blocks 6, the bottom ends of the two sides of the U-shaped box 1 are symmetrically equipped with rotating blocks 5, and rotating shafts 4 are installed between the symmetrical rotating blocks 5, and the number of installed rotating shafts 4 is at least There are more than three groups, and a baffle plate 7 is fixedly installed at one end of the U-shaped box 1 .

[0012] Both sides of the forklift frame 2 are symmetrically provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com