Telescopic double-sided LED light tube

A LED light tube and double-sided light-emitting technology, applied in the field of LED light tubes, can solve the problems of light box error, fixed size of LED light tubes, difficulty in installation and fixing, etc., and achieve simple and convenient disassembly, ingenious structural design, and wide application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

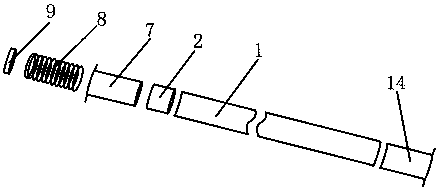

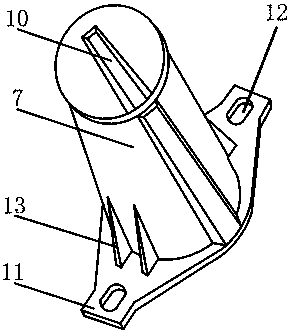

[0026] Such as Figure 1 to Figure 4 As shown, the telescopic double-sided light-emitting LED lamp tube disclosed by the present invention mainly includes a LED lamp main body, a first plug is provided at one end of the LED lamp main body, and a first plug is provided on the outer wall of the first plug. There are two slide blocks, the two slide blocks are located on the same straight line, and an elastic device is installed on the slide block.

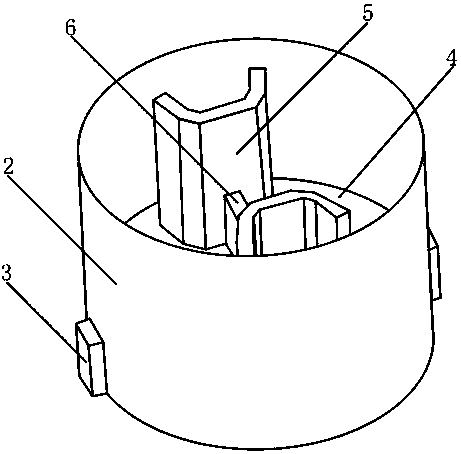

[0027] Wherein, the above-mentioned first plug is a hollow cylindrical structure, and the first plug divides its internal cavity into two parts by a partition, and two clamping strips are arranged oppositely on one side of the partition, and the two A connecting block is arranged between the clamping strips, and the two clamping strips can be clamped with the end of the main body of the LED light tube.

[0028] The above-mentioned elastic device includes a sliding part, a spring and an end cover, wherein the sliding part is a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com