Measuring device for thermal explosion critical pressure of pyrotechnic powder column

A technology of critical pressure and measuring devices, which is applied in measuring devices, force/torque/work measuring instruments, material explosives, etc., can solve problems such as ignoring effects, and achieve the effect of reducing test costs and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

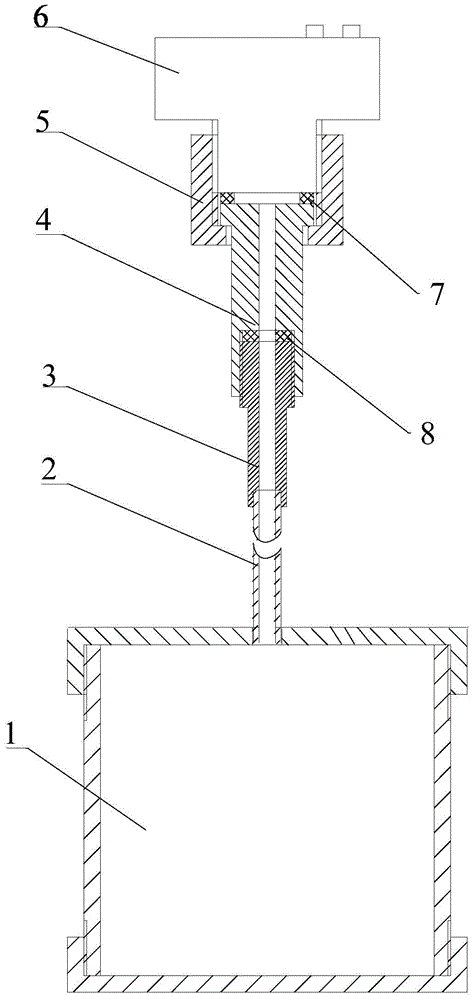

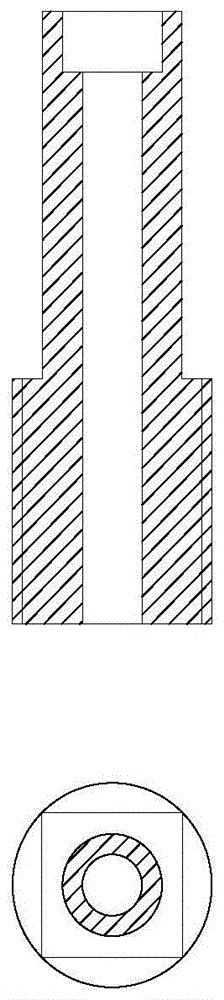

[0015] refer to Figure 1 to Figure 5 , the present embodiment gives a specific structure, manufacturing and assembly example of a thermal explosion critical pressure measuring device for propellant and explosive grains. The thermal explosion critical pressure measuring device of propellant powder column at least includes a simulated burner bomb 1 , a conduit 2 , a gas nozzle 3 , an adapter 4 , a nut 5 , a pressure sensor 6 , a sealing ring 7 and a sealing ring 8 .

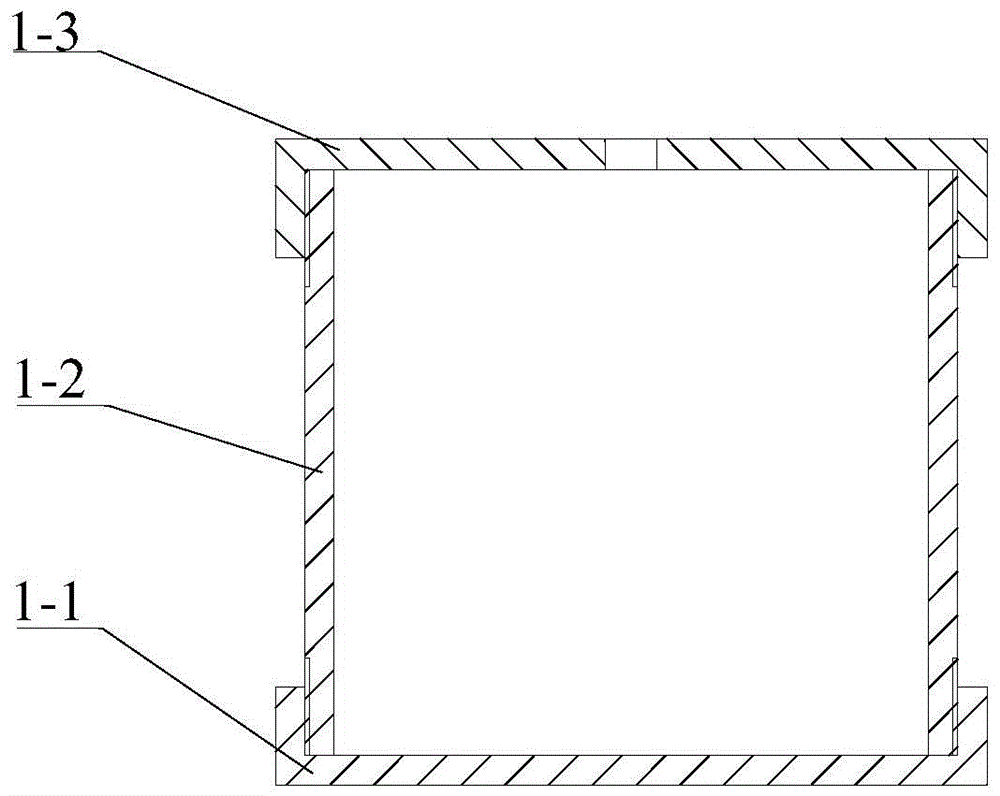

[0016] see figure 2 , the simulated burner bomb 1 is composed of a threaded end cap 1-1, a projectile body 1-2 and a threaded end cap with holes 1-3. The projectile 1-2 is made of stainless steel, with openings at both ends, external threads at the upper and lower ends, the thread height is 6mm-10mm, the outer diameter of the projectile 1-2 is 36mm-60mm, the inner diameter is 30mm-50mm, and the height is 30mm ~50mm; the threaded end cap 1-1 and the threaded end cap with holes 1-3 are made of stainless steel. Th...

Embodiment 2

[0023] This embodiment describes the measurement of the thermal explosion critical pressure of the AP powder column by using the thermal explosion critical pressure measurement device of the propellant column manufactured in Example 1.

[0024] In this example, the internal diameter of the simulated combustion bomb is 42mm, the external diameter is 48mm, the height is 42mm, the wall thickness of the upper and lower end caps is 4mm; the internal diameter of the gas conduit is 3mm, the external diameter is 5mm, and the length is 1000mm; the operating temperature range of the pressure sensor is -40°C ~160°C, the outer diameter of the interface thread is 20mm.

[0025] Weld the two ends of the conduit 2 with the gas nozzle 3 and the central through hole of the holed threaded end cap 1-3 of the mock-up bomb 1 in advance, and the weld seam is tightly sealed; the lower end of the mock-up bomb 1 is threaded 1-1 sealing, put the formed AP powder column with a size of Ф40×40mm into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com