Waterproof two side-pluggable USB connector and manufacturing method thereof

A connector, positive and negative plug-in technology, applied in the manufacture, connection, and parts of the connection device of the contact box/base, it can solve the problems of simultaneous fixed positioning, inability to realize function upgrades, inability to be backward compatible, etc., to achieve The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

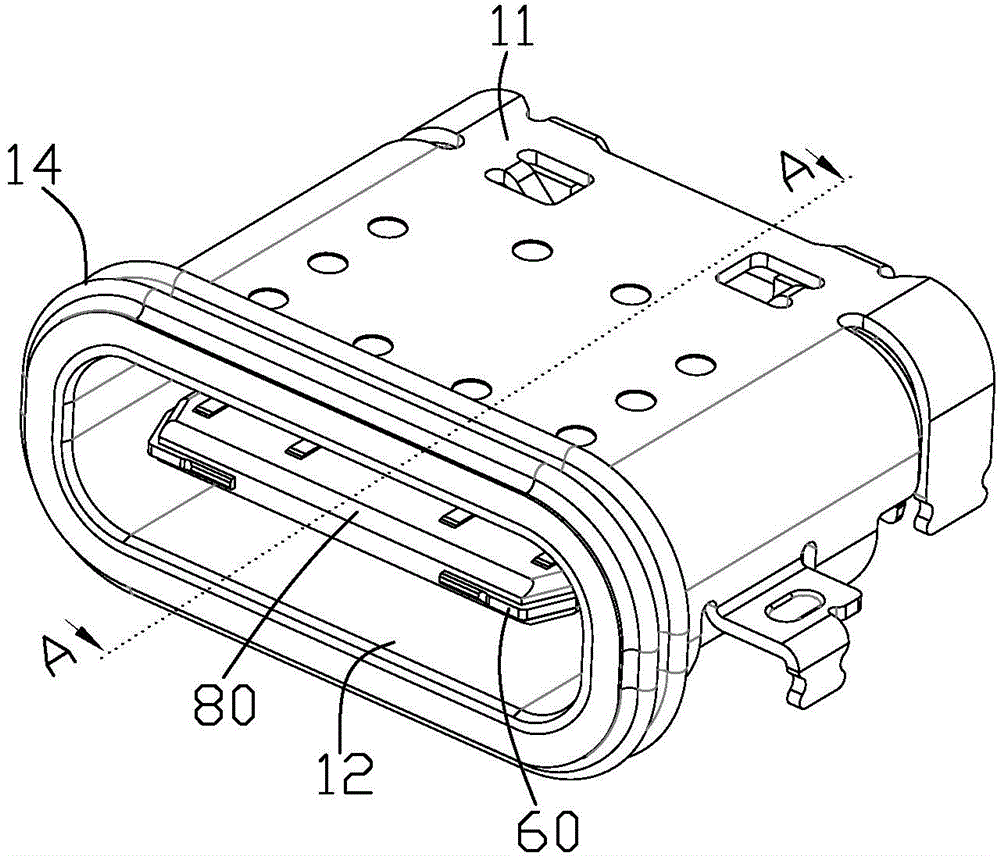

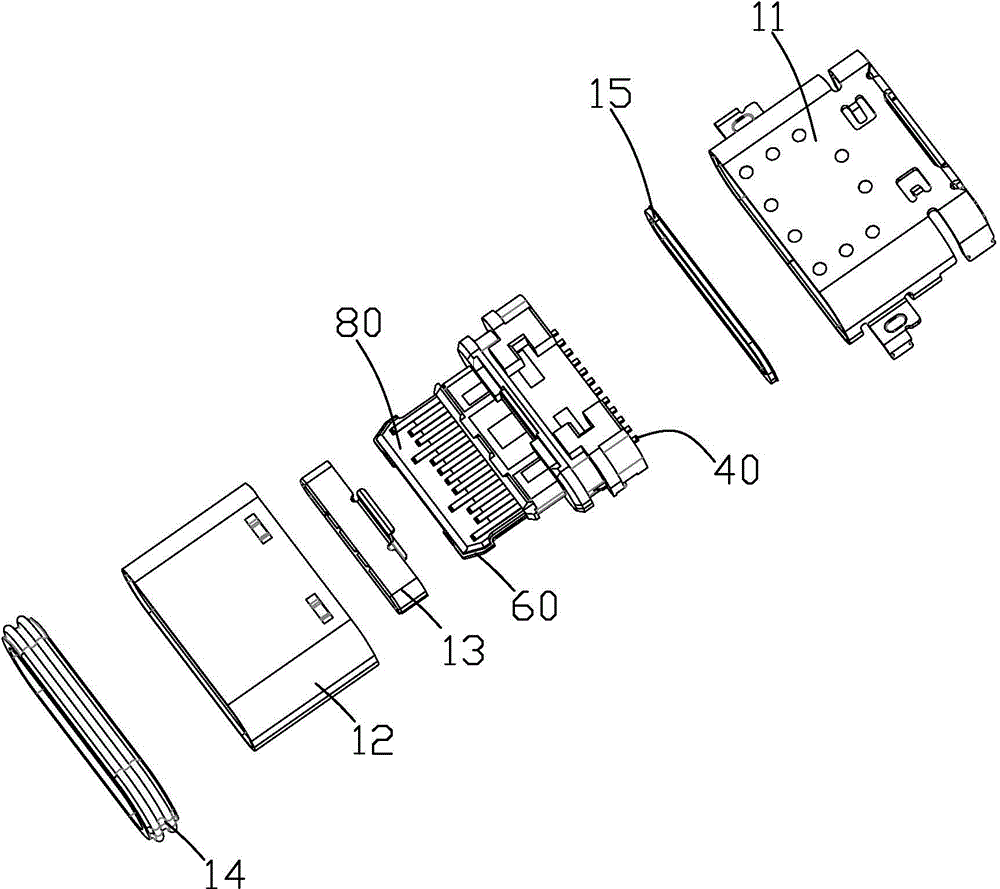

[0032] The waterproof front and back plug-in USB connector of this application is a USB3.1 Type C socket connector. A new interface with high speed.

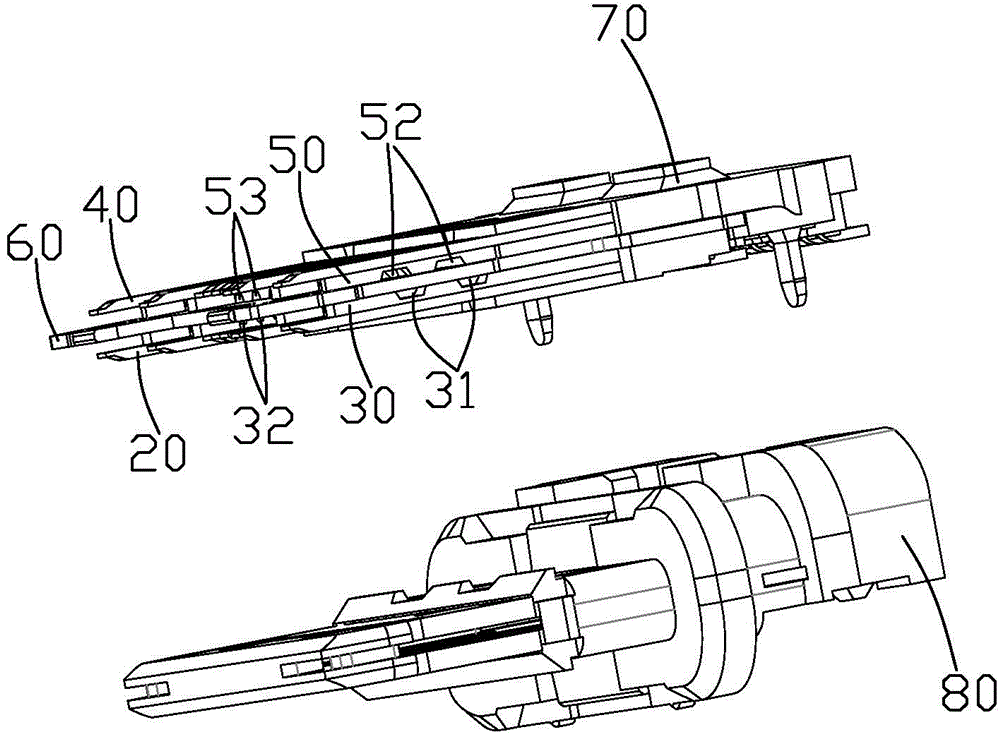

[0033] see Figure 1 to Figure 6As shown, the waterproof front and back plug USB connector of the present application includes a first terminal group 40, a first insulator 50 integrally formed with the first terminal group 40, a second terminal group 20, and an integral body with the second terminal group 20. The second insulator 30 formed in the city, the metal isolation middle plate 60, the third insulator 70 integrally forming the metal isolation middle plate 60 on the first terminal group 40 and the second insulator 50, the first terminal group The group 40, the first insulator 50, the second terminal group 20, the second insulator 30, the metal isolation middle plate 60, and the third insulator 70 are integrally formed and covered as a whole insulating shell 80, and the insulating shell 80 installed outside the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com