LED multi-group constant current drive circuit

A technology of constant current drive and circuit, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems that hinder the industrialization of LED lighting products, the peripheral circuit of LED driver chip is complicated, and the service life of LED lamps is shortened, etc., to achieve Reduced junction temperature, reduced heat sink area, and small light attenuation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings, but the present invention shall not be limited in any way, and any changes or improvements made based on the teaching of the present invention shall fall within the scope of protection of the present invention.

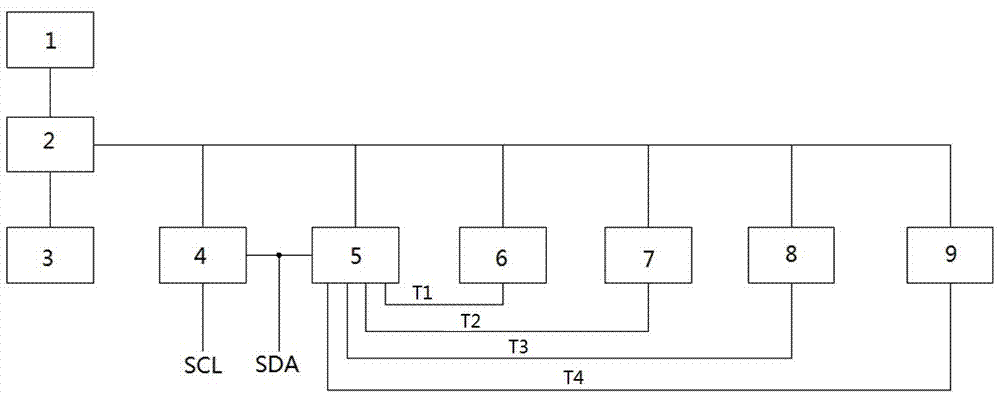

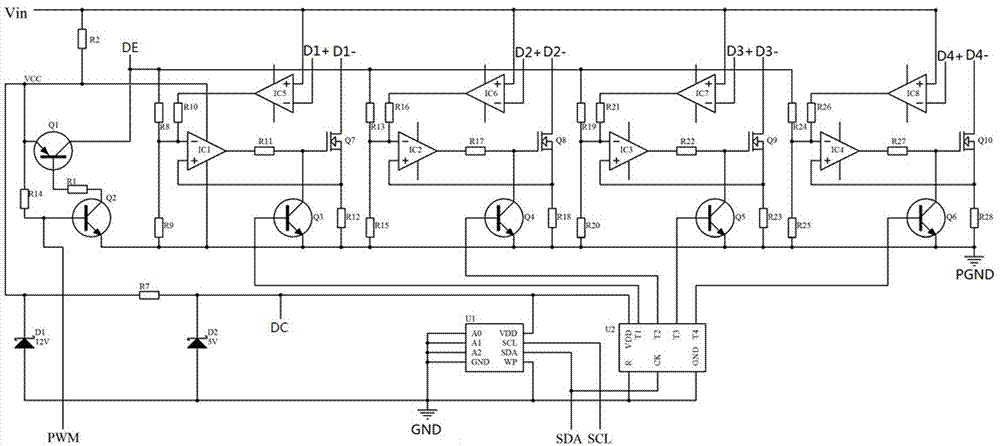

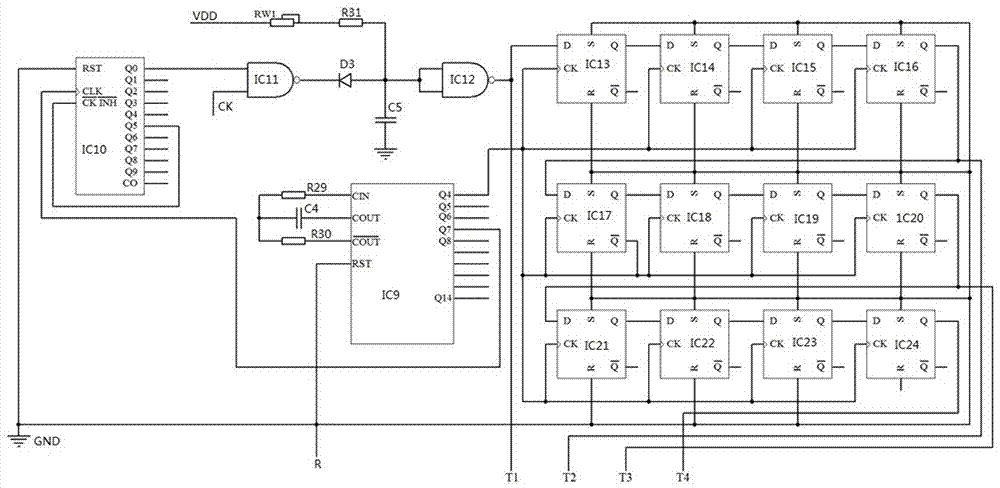

[0014] figure 1 The principle diagram of the LED multi-group constant current drive circuit of the present invention is given. In the present invention, the LED multi-group constant current drive circuit includes a power supply unit 1, a reference voltage unit 2, a dimming unit 3, a data storage unit 4, A phase shift control unit 5 and at least one group of LED lamp bead string constant current detection and control units; the power supply unit 1 and the dimming unit 3 are respectively connected to the reference voltage unit 2, and the reference voltage unit 2 is respectively connected to the data storage unit 4, The phase-shift control unit 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com