Precipitation tank without vent for precise solid-liquid separation of 1,3-cyclohexanedione

A cyclohexanedione solid-liquid technology without vent holes is applied in the field of sedimentation tanks, which can solve problems such as waste of material and liquid, and achieve the effects of reducing waste and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

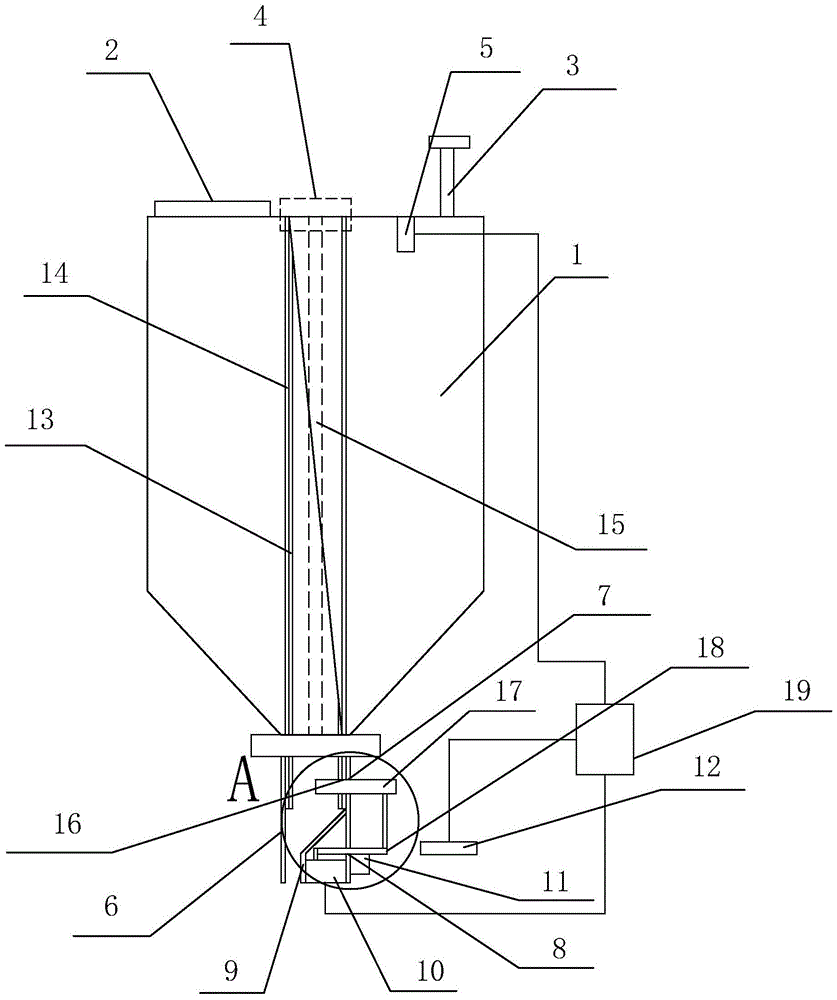

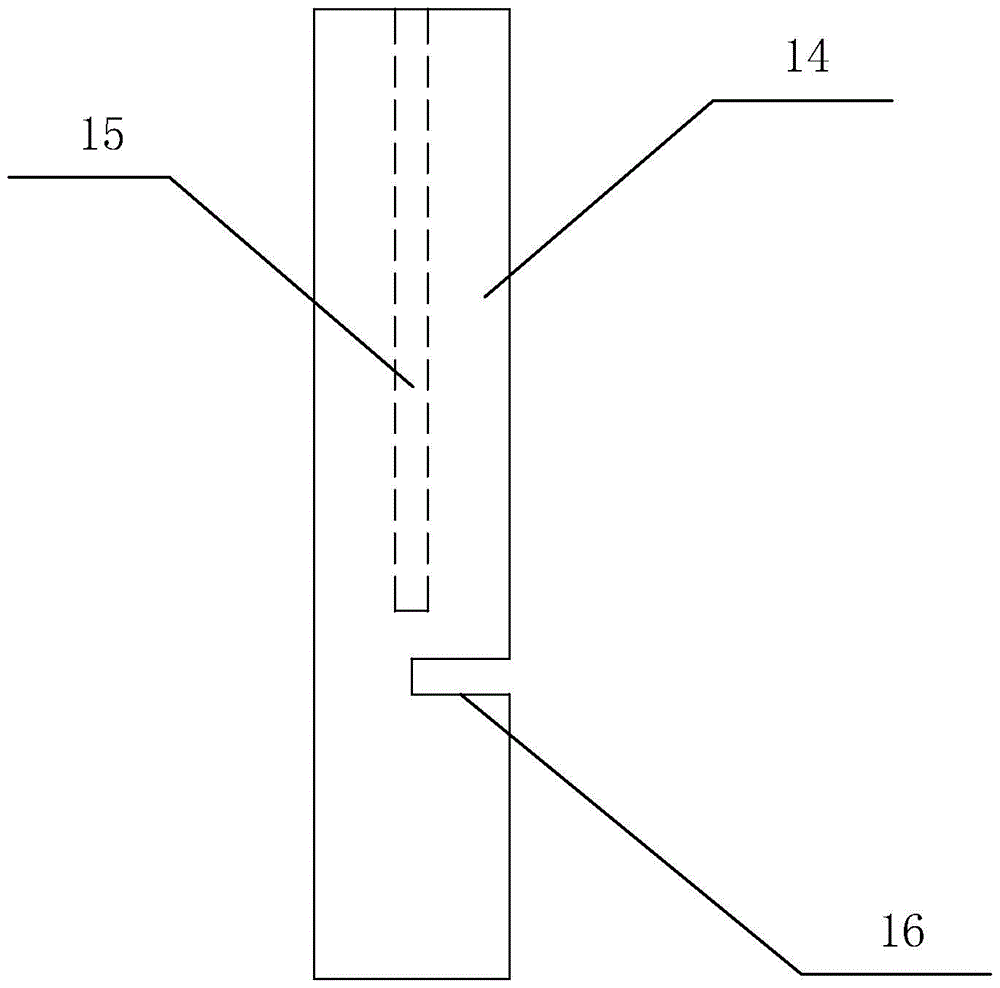

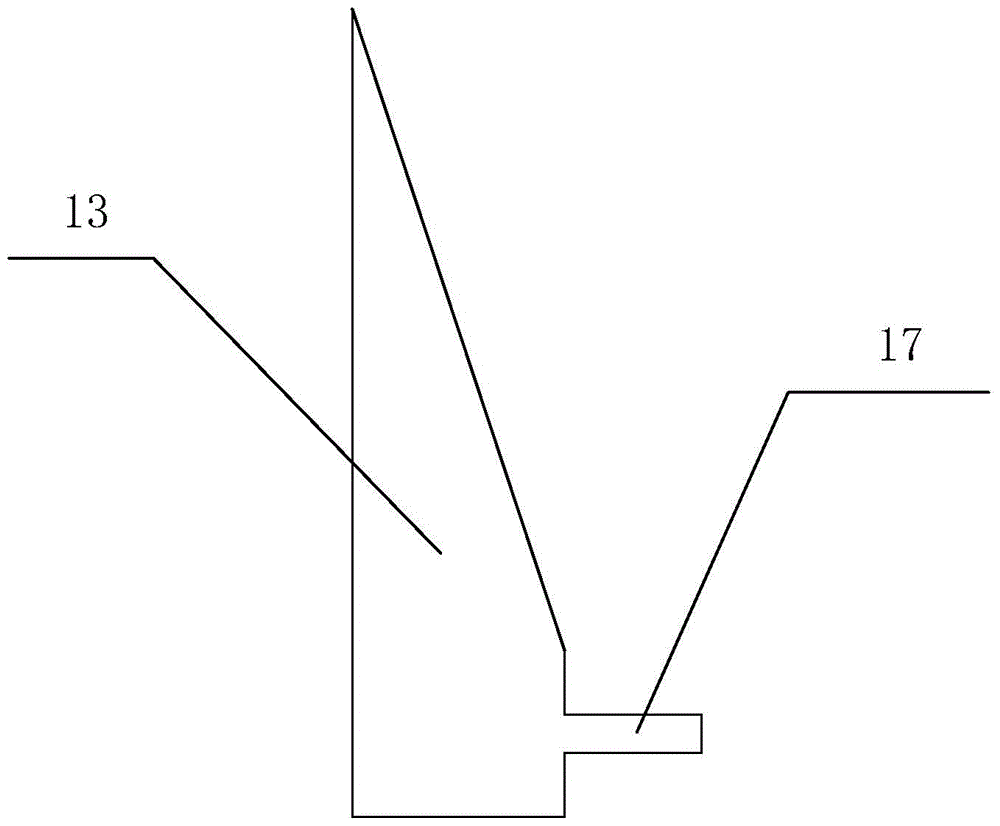

[0017] In order to further understand the present invention, the present invention will be described below in conjunction with the accompanying drawings.

[0018] Such as Figure 1-4 As shown, a settling tank without vent holes for precise solid-liquid separation of 1,3-cyclohexanedione provided in this embodiment is characterized in that it includes a tank body 1, and the top left side of the tank body 1 A manhole 2 is provided, a feed inlet 3 is provided on the right side of the top of the tank body 1, a circular through hole 4 is provided in the middle of the top of the tank body 1, and a circular through hole 4 is provided between the feed inlet 3 and the circular through hole 4. There is an infrared range finder 5, the transmitting end of the infrared range finder 5 is vertically downward, and the middle position of the bottom of the tank body 1 is provided with a discharge port 6, and the discharge port 6 is provided with a first semicircular arc-shaped passageway. hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com