a tapping station

A tapping and base technology, applied in the field of tapping station, can solve problems such as processing steps, lack of tapping positioning, tapping damage, etc., and achieve the effect of improving processing efficiency, saving processing steps, and saving processing steps

Active Publication Date: 2017-03-15

DONGGUAN FOUROCEAN MACHINERY TOOLS

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing overall suspension type in-mold tapping machine can only complete one step in the part tapping process, that is, it can only tap. However, in the actual tapping process, it also includes part fixing and tapping detection. and other steps, the existing integral suspension type in-mold tapping machine does not have the above functions, which makes the tapping process of the parts cannot be completely processed in one station, and other equipment is needed for assistance during and after processing. , which leads to unsmooth continuous production. At the same time, due to the lack of tapping positioning and tapping detection, if other auxiliary equipment fails, or if there is no other auxiliary equipment, the tapping machine will have wrong tapping or missing tapping, which will also easily cause Tapping wrong damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

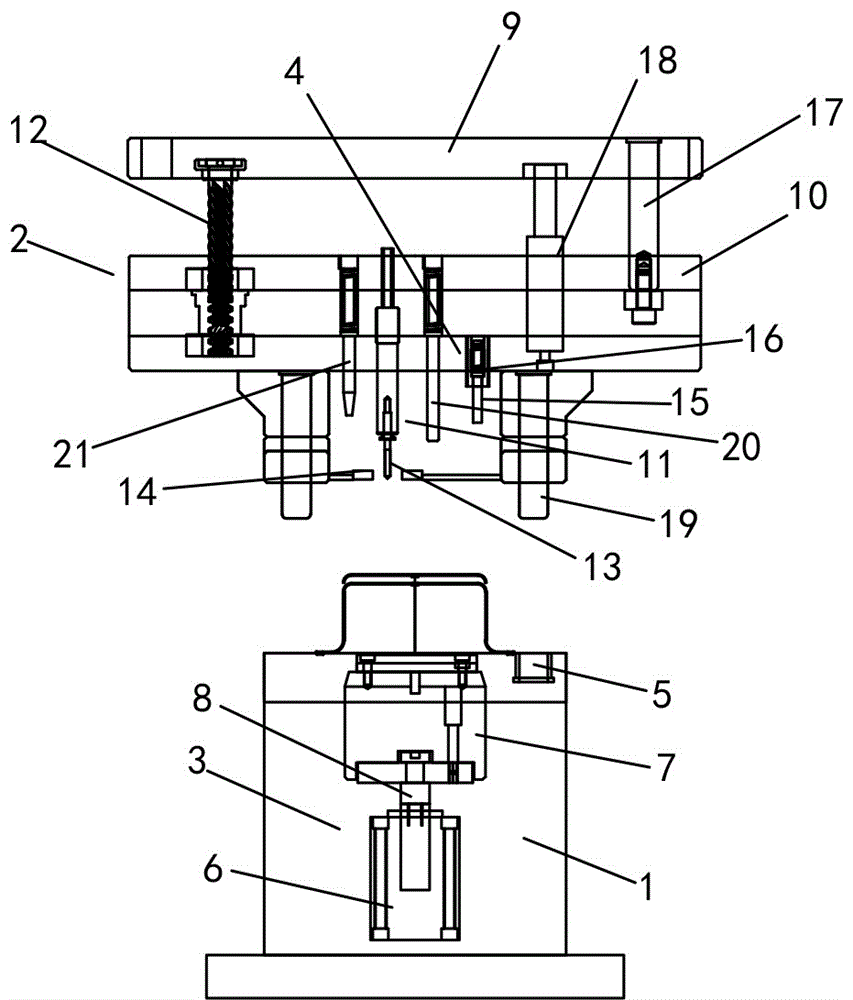

[0052] Such as figure 1 As shown, the present invention includes a base 1, a pre-positioning mechanism 3, an upper hanging tapping mechanism 2, a detection mechanism 4, and a control unit,

[0053] A number of positioning guide holes 5 are provided on the upper surface of the base 1;

[0054] The pre-positioning mechanism 3 is arranged in the base 1, and the upper hanging tapping mechanism 2 is installed directly above the base 1;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a tapping station. The tapping station comprises a base, a pre-positioning mechanism, an upper hanging type tapping mechanism, a detecting mechanism and a control unit. The pre-positioning mechanism is arranged in the base. The upper hanging type tapping mechanism is installed over the base. The detecting mechanism is connected with the hanging type tapping mechanism. The pre-positioning mechanism comprises a cylinder, a positioning block and a connecting rod. The cylinder is arranged in the base. The positioning block is embedded in the base and connected with the cylinder through the connecting rod. The upper hanging type tapping mechanism comprises a base plate, a machine body, a tapping assembly, a transmission assembly, copper alloy and a screw. The tapping station is simple in structure and reasonable in design, a tapping procedure can be completed on one station through pre-positioning, re-positioning, pre-pressing, re-detecting and re-tapping, one-stop type machining is achieved, machining steps are saved, and machining efficiency is improved.

Description

Technical field [0001] The invention relates to a tapping equipment, in particular to a tapping station which can realize the integration of tapping positioning, tapping and tapping detection. Background technique [0002] The in-mold tapping machine is a device that cooperates with continuous hardware molds to quickly perform screw hole processing during the stamping and processing of hardware parts. It is the most advanced screw hole forming process for hardware parts at present. It breaks the traditional processing method. Its core is to "integrate" the traditional "stamping" and "tapping" technology together and directly form it in the mold. Since the in-mold tapping effectively avoids secondary operations (stamping first, then tapping), the production efficiency is greatly improved, and it is especially suitable for continuous die, progressive die, and precision die. [0003] In order to save space in the mold and improve the versatility of the tapping machine, many in-mold t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23G1/18B23G1/44

CPCB23G1/18B23G1/44

Inventor 黄剑辉郑镇坚

Owner DONGGUAN FOUROCEAN MACHINERY TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com