Carpentry planer

A planing and woodworking technology, which is applied to wood processing equipment, manufacturing tools, and processing machines for manufacturing flat surfaces, etc. It can solve the problems of wool limit that cannot be different in width, high reject rate of processed products, and uneven planing of wool, etc. , to achieve the effect of high processing efficiency, high yield and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

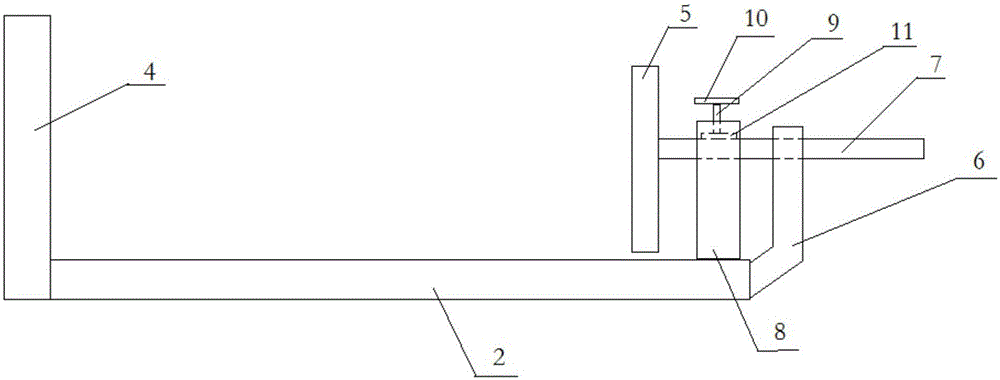

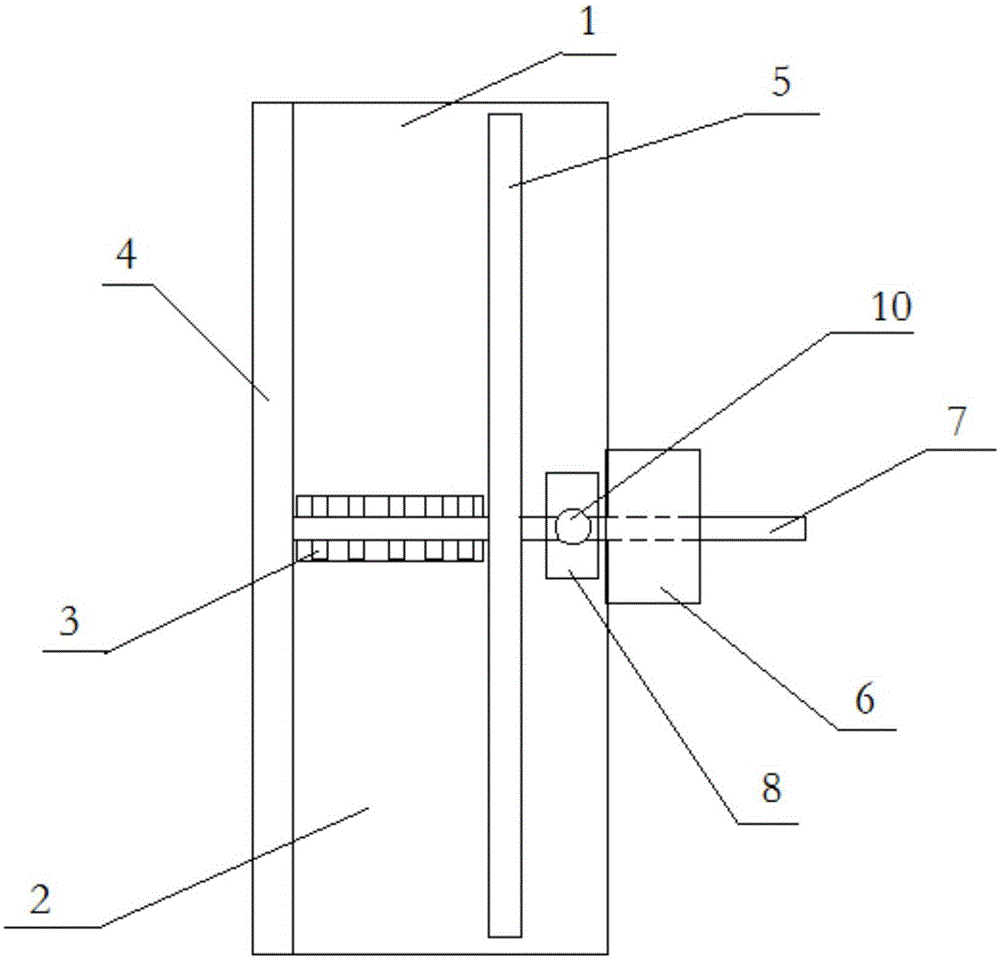

[0015] Such as figure 1 with 2 As shown, a woodworking planer includes a workbench body, a knife groove and a connecting device, and the workbench body includes a front workbench 1 and a rear workbench 2, and the front workbench 1 and the rear workbench 2 are arranged in a straight line. cloth, on the front workbench 1 and the rear workbench 2 respectively, a sipe is respectively provided with planing knives 3 for planing in the sipe, on one side of the workbench body Be provided with baffle plate 4, be provided with movable plate 5 on the other side of described workbench body, described movable plate 5 is fixed with described workbench body by described connecting device, and describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com