Three-time ejection control mechanism

A technology of control mechanism and secondary ejection, which is applied in the field of tertiary ejection control mechanism to achieve the effects of stable work, reduced production cost, guaranteed stability, accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

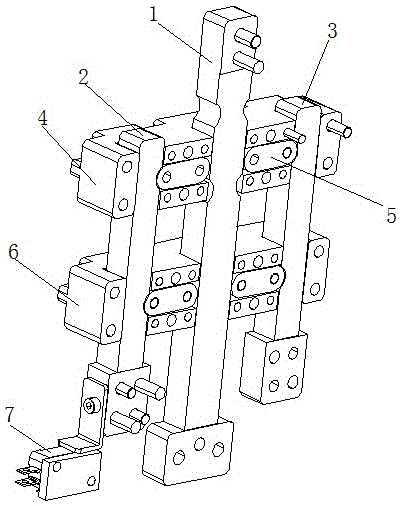

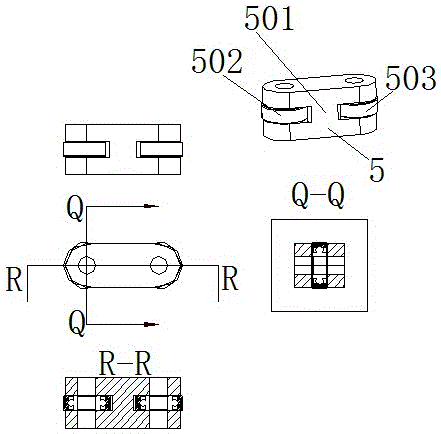

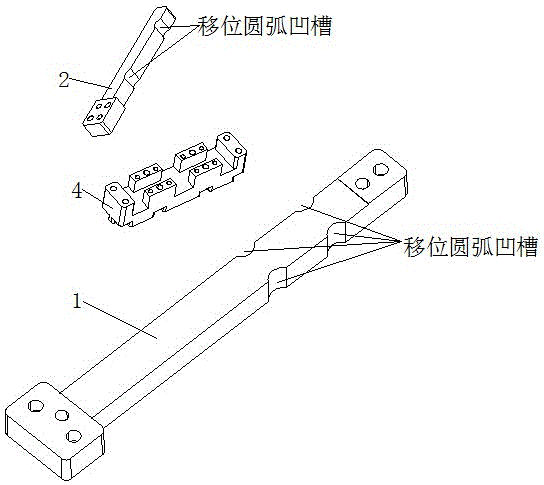

[0017] Figure 1-7 Shown is a relevant explanatory diagram of the present invention; a three-time ejection control mechanism, including a main lock block 1, a left branch lock block 2, a right branch lock block 3, a primary ejection lock groove 4, a sliding lock cylinder 5, Secondary ejection lock groove 6, reset travel switch 7, primary ejection plate reset lever 8, secondary ejection plate reset lever 9, such as figure 1 , Figure 5 shown.

[0018] The main locking block 1 is installed on the movable template of the mold through the upper end of the screw, and the lower end is installed on the bottom plate of the mold; it is provided with a primary ejection and a secondary ejection shift arc groove; the left branch locking block 2, The right support lock block 3 relies on the screw hole and pin hole at the bottom end and is installed on the top plate of the three-time ejection of the mold through the screw and the pin, and its upper end passes through the first ejection lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com