Application method of molding plastic extruding machine recognizing material varieties

A technology of extruders and varieties, applied in the field of molding extruders, can solve the problems of unknowable and wrong operation, and achieve the effect of avoiding material scattering, convenient operation, and less additional operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

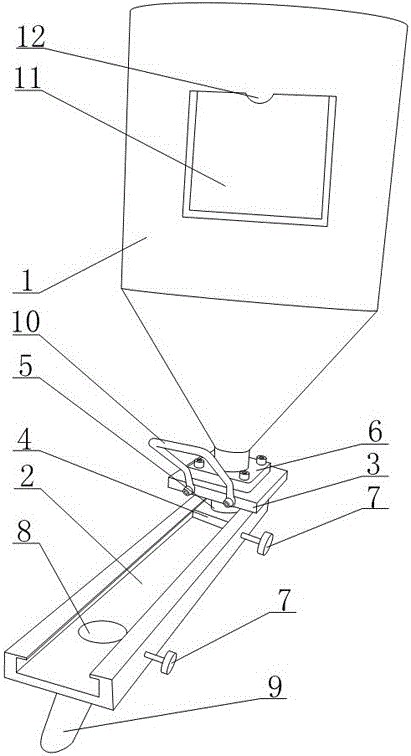

[0021] Such as figure 1 As shown, a method of using a molding extruder for identifying material types of the present invention includes a hopper body 1, which includes a cylindrical storage barrel, and a funnel-shaped discharge structure is connected to the bottom of the storage barrel. An identification tag storage belt 11 is provided on the storage cylinder. The identification tag storage belt 11 is rectangular as a whole, and its two sides and bottom edges are bonded to the storage cylinder. Only the upper side is not bonded to the storage cylinder. To put the material identification plate into the identification plate storage belt 11, there is a notch 12 on the upper side, which is convenient for fingers to hold the material identification plate; it also includes a chute 2 fixedly installed on the extruder. The chute is a rectangular parallelepiped as a whole and has an opening on the surface , The inside is a cavity, the internal width of the chute 2 is greater than the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com