Lifting mechanism and lifting floor and automobile using the lifting mechanism

A lifting mechanism and floor technology, which is applied in the direction of freight vehicles, motor vehicles, and article transport vehicles, can solve the problems of large noise, high energy consumption, and large space occupied by the lifting floor, achieving small space, energy saving, The effect of reducing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

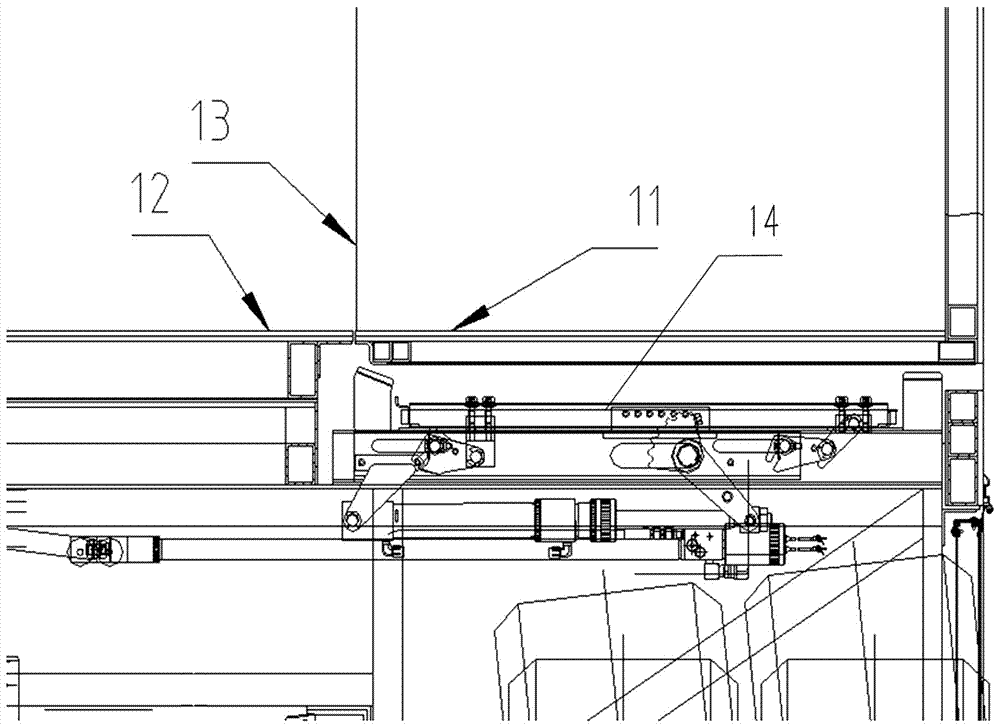

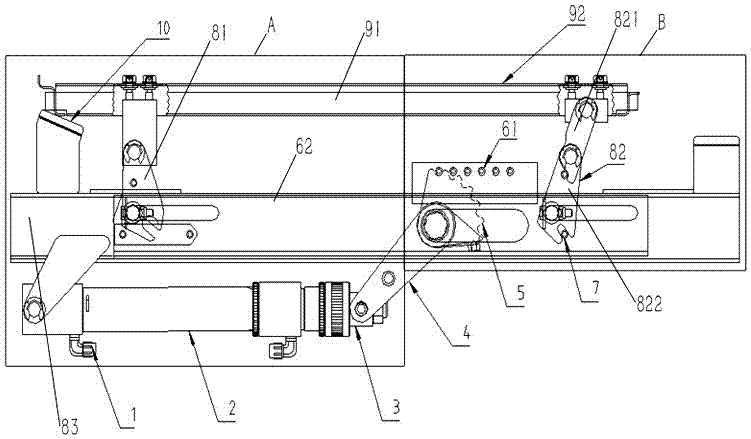

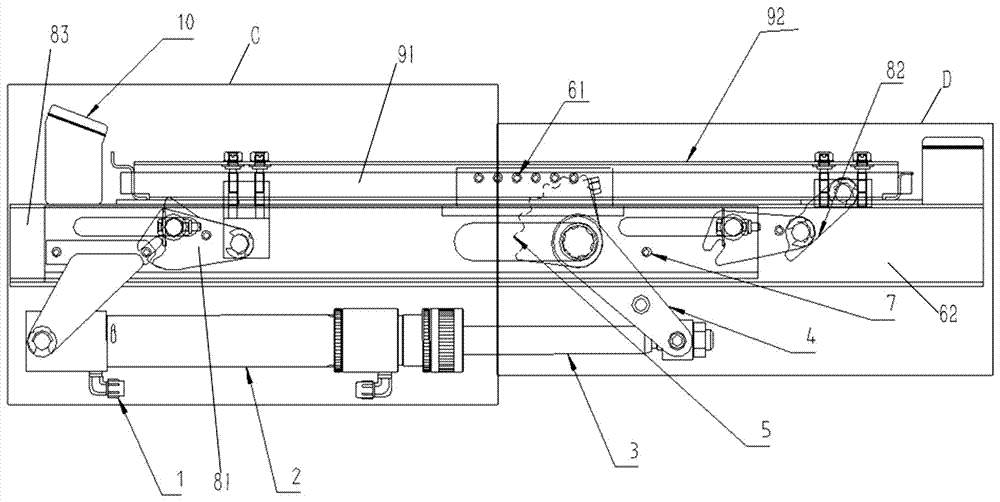

[0026] The embodiment of automobile among the present invention: as Figure 1 to Figure 7 As shown, the car is a caravan with a drawer compartment 13, including the drawer compartment 13 provided on the car body and its side wall. The drawer compartment 13 can be moved from the Pulling out and inserting back on the car body, when the drawer cabin 13 is in the inserted back state, the bottom of the cabin floor 11 of the drawer cabin 13 is provided with a lifting floor 14, and the lifting floor 14 is mainly composed of a floor fixing frame 83, a lifting mechanism and a floor. Composed of three parts, the floor fixing frame 83 is fixed on the car body, and the lifting mechanism is a lifting device for the movable floor of the drawer cabin 13 of a caravan, and the floor can be lifted relative to the floor fixing frame 83 under the drive of the lifting mechanism.

[0027] Floor fixing frame 83 comprises the base frame that is fixed on the floor frame of car body, and the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com