Concrete panel structure applied to high-toe wall and construction method

A technology of concrete slabs and high toe walls, which is applied in the direction of dams, barrages, weirs, etc., can solve the problems that the surrounding plinths cannot be connected smoothly, the excavation depth is large, and the overall stability of the slab is affected, so as to achieve safety and reliability. Strengthening, smoothing the axis, and increasing the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

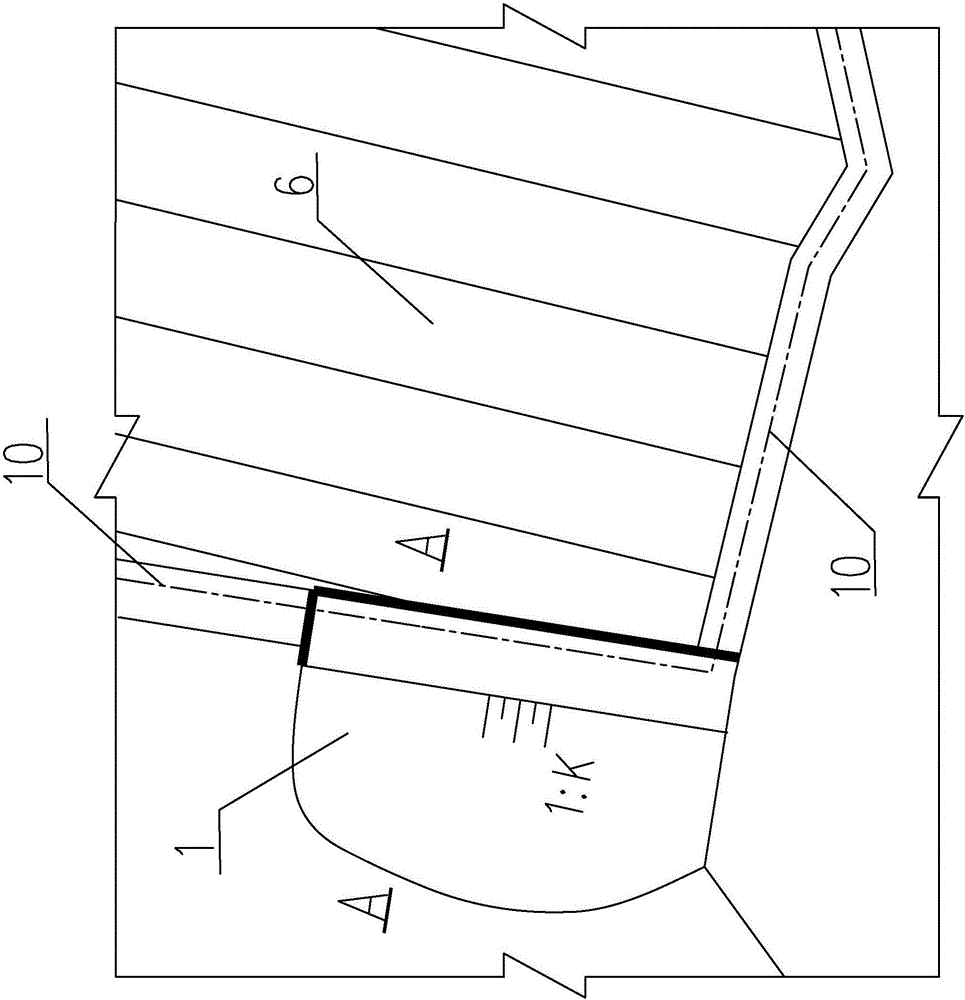

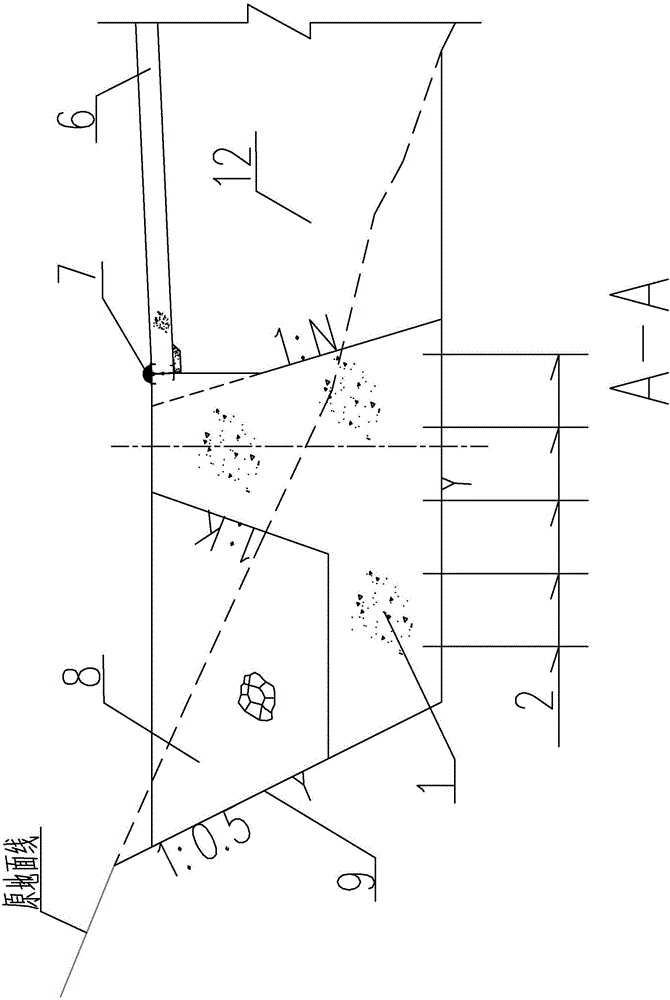

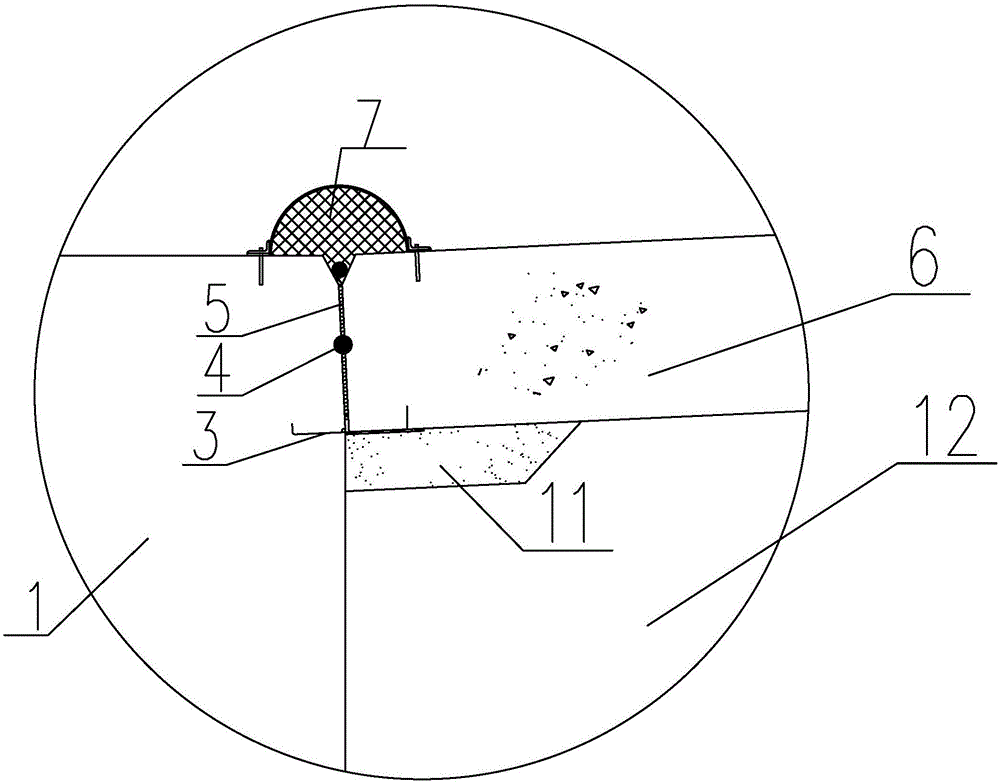

[0019] Such as figure 1 , figure 2 As shown, the present embodiment is a concrete panel structure and construction method using a high toe wall. The structure includes a concrete panel 6, a rockfill layer 12 below the concrete panel, a plinth 10 arranged around the concrete panel 6, and The toe slab 10 arranged along the mountain slope is excavated to form a side slope 9 of 1:0.5; In between, an asphaltic sand cushion 11 is arranged near the toe wall 1.

[0020] In this embodiment, the side of the toe wall 1 close to the concrete panel 6 is a slope whose bottom expands outwards and connects with the rockfill layer 12. The slope is 1:N, and N=0.3~0.7. The upper part of the slope should be as close as possible to the concrete. The panels 6 are connected orthogonally; the side of the toe wall 1 next to the side slope 9 is a balance platform, and forms an inverted trapezoidal groove with the side slope, and the groove is backfilled with gravel material 8; the toe wall 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com