Tensioning device for applying pretensioning force to fiber cloth materials and tensioning method of tensioning device

A technology for applying pre-tensioning and tensioning devices to fabrics is applied in the processing of building materials, building maintenance, construction, etc. It can solve the problems of uneven force on fiber fabrics and difficult force measurement, and achieve good anchoring effect and simple operation. , widely used effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

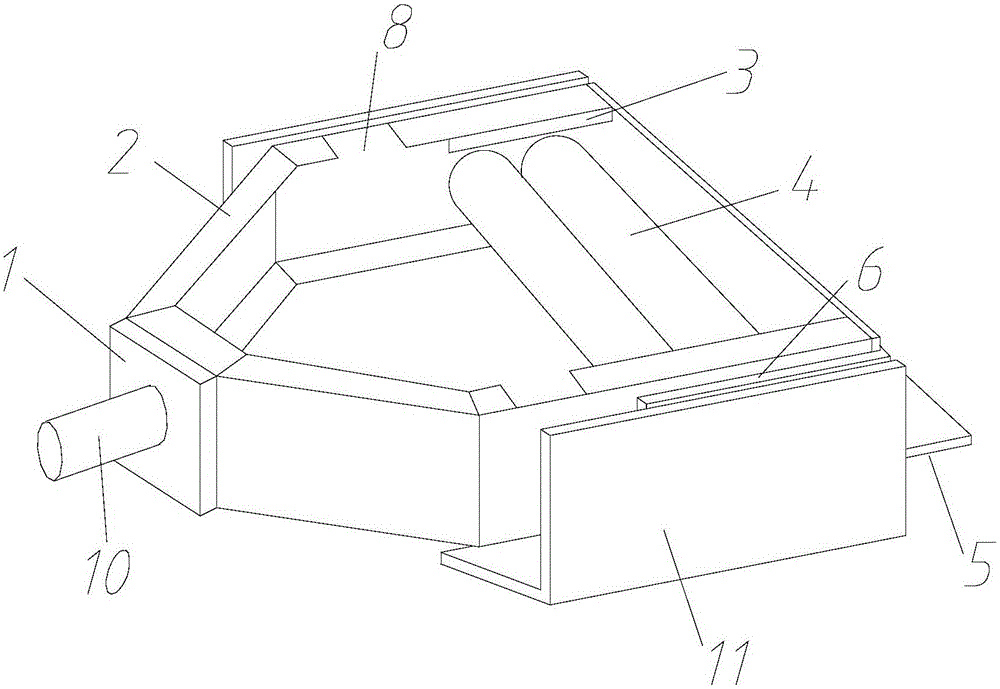

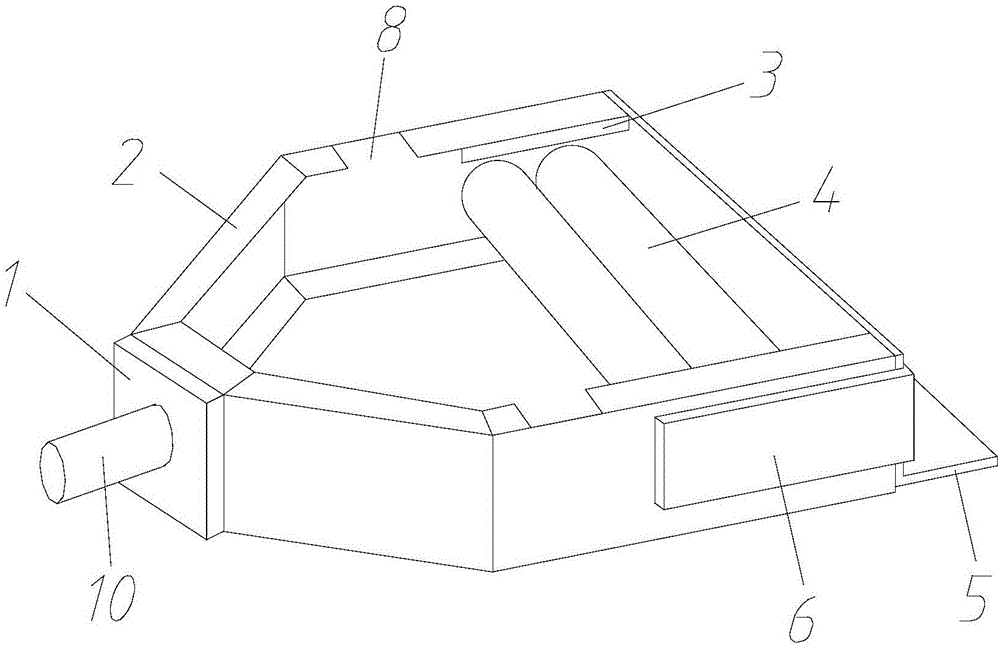

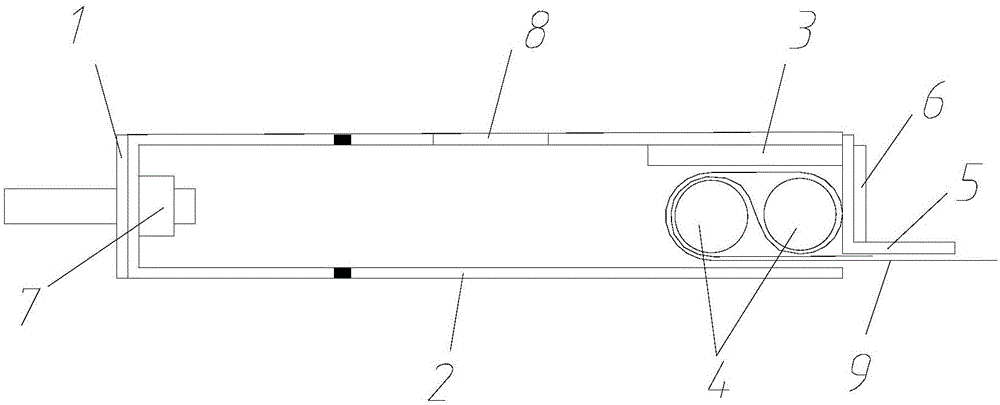

[0037] Refer to attached Figure 1-3 As shown in the figure, a tensioning device for applying pretension to the fiber cloth includes a steel baffle slideway 11 fixed at both ends, and a rolling groove 2 is arranged in the slideway 11, and can be placed in the slideway 11. 11 slide freely.

[0038] Two rollers 4 are put into the rolling groove 2 through the upper flange opening 8 of the rolling groove 2, and they can roll along the horizontal direction of the rolling groove 2, and are used for winding and self-locking fixing of the fiber cloth material 9.

[0039] An L-shaped baffle 5 is provided at the tension end of the rolling groove 2 for resisting the roller 4 .

[0040] The anchoring end of the rolling groove 2 has a trapezoidal structure, and a reinforcing steel plate 1 is provided at the end.

[0041] A backing plate 3 is also provided at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com