Array type eddy current detection probe with hydraulic adjusting device and detection method thereof

A technology of hydraulic adjustment device and eddy current detection probe, which is applied in measurement devices, instruments, material analysis by electromagnetic means, etc., can solve problems such as uneven force and achieve effective detection results and best test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

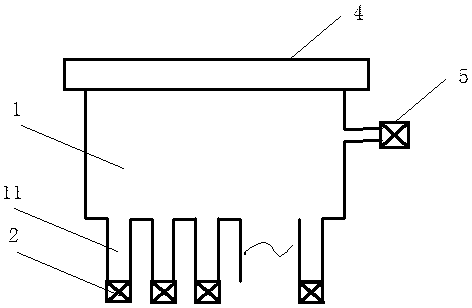

[0039] Example 1, such as figure 1 , figure 2 and image 3 as shown,

[0040] The present invention discloses a hydraulic adjustment device for an array type eddy current detection probe, which is used for flawless detection of metal surfaces in electromagnetic eddy current detection. The hydraulic adjustment device includes a hydraulic adjustment chamber 1 and more than one hydraulic column 11. The array of hydraulic columns 11 is distributed on the surface of the hydraulic adjustment cavity 1, and each hydraulic column 11 is used to correspond to a probe coil; wherein, the hydraulic adjustment cavity 1 and the hydraulic column 11 are made of deformable soft materials such as soft rubber As a result, the hydraulic adjustment chamber 1 and the hydraulic column 11 are connected as an overall airtight communication structure that allows liquid or gas to flow.

[0041] Wherein, the hydraulic adjustment chamber 1 is a cylinder, and the hydraulic columns 11 of the same cylinder...

Embodiment 2

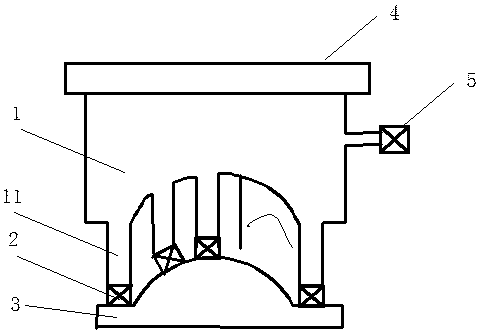

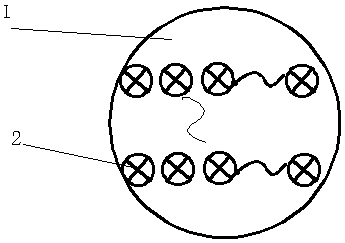

[0061] Such as Figure 4 , 5 , 6, and 7, the difference from Embodiment 1 is that the hydraulic adjustment chamber 1 is a semicircular sphere, except that it has the same technical characteristics and functions as Embodiment 1, such as Figure 6 As shown, when the hydraulic adjustment chamber 1 is flattened, it has the effect of changing the elastic force of the hydraulic adjustment device. Additionally, if Figure 7 As shown, the hydraulic column 11 and the probe coil are distributed in a circular arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com