Massager driving device

A driving device and massager technology, applied in vibration massage, massage auxiliary products, physical therapy and other directions, can solve the problems of insufficient bearing capacity and uneven force of parallel double chutes, so as to prolong the life, avoid skew, and ensure the The effect of force stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

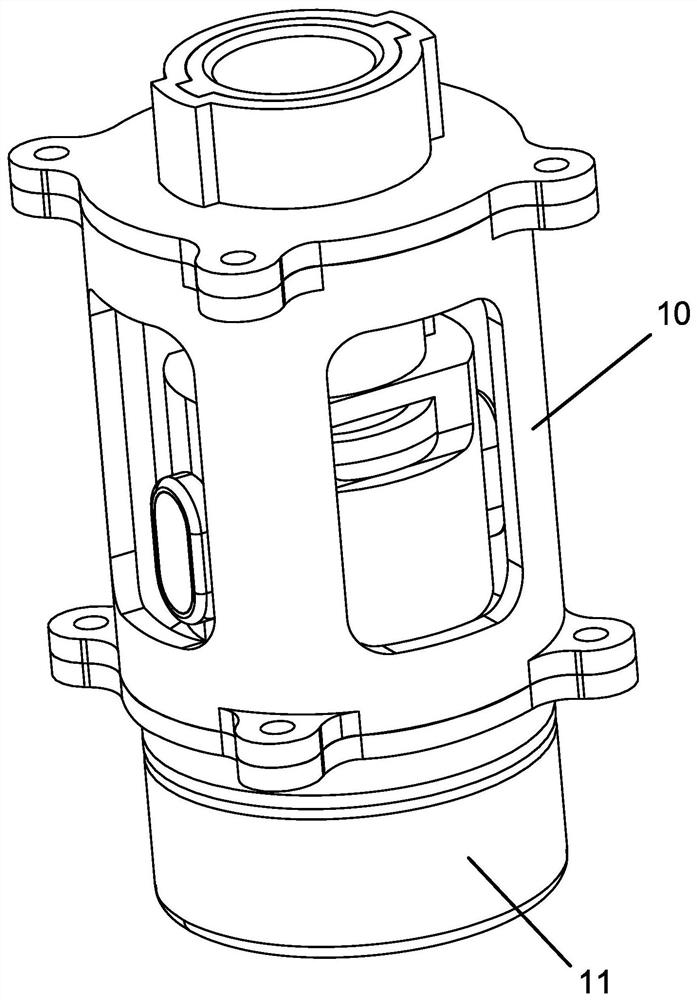

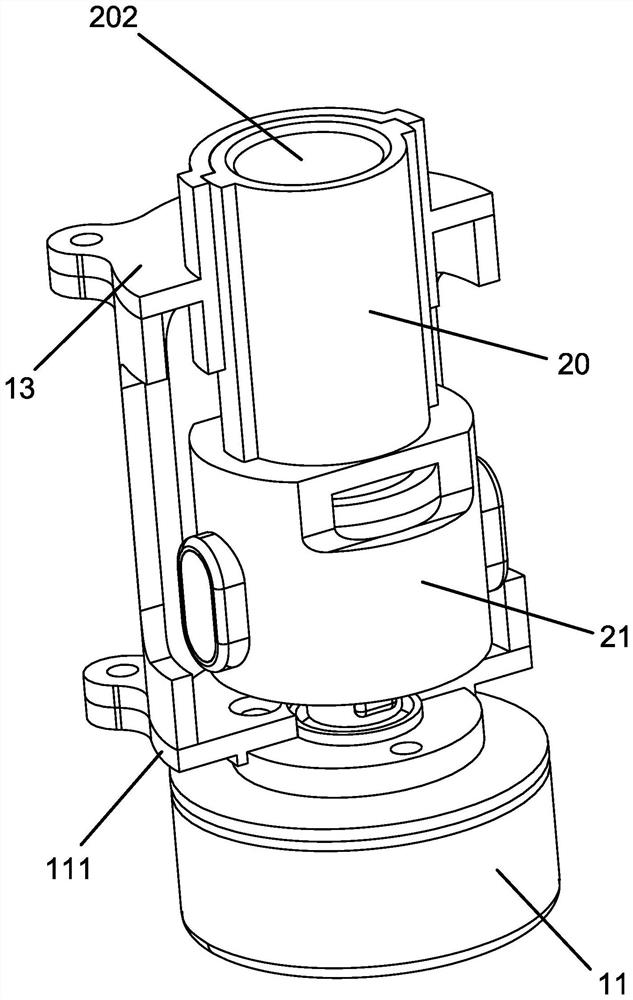

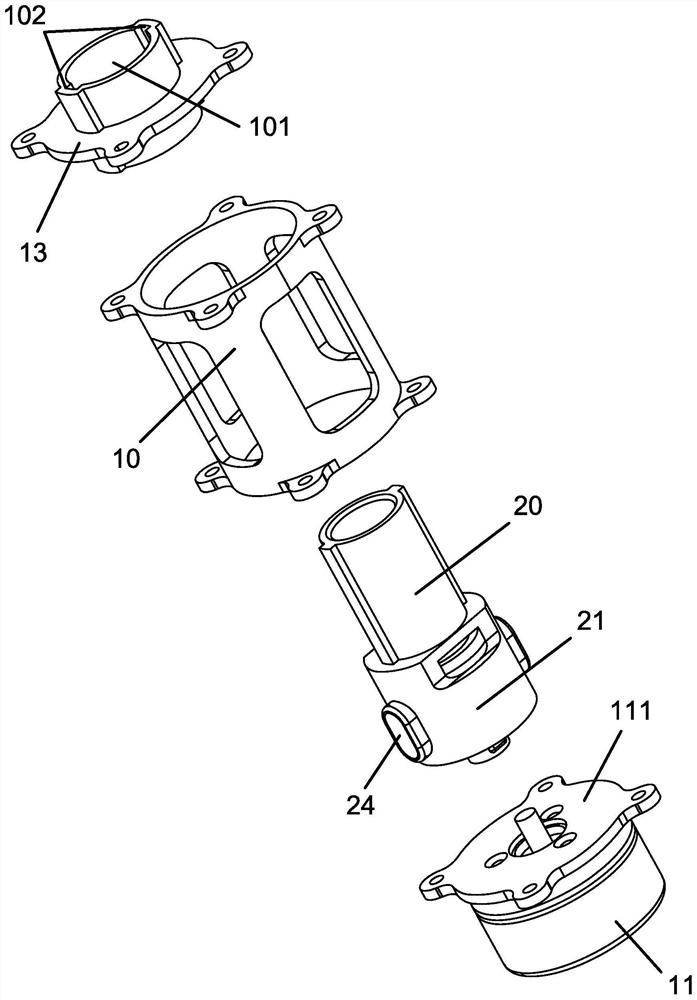

[0027] refer to Figure 1 to Figure 5 ,like Figure 1 to Figure 5 The shown driving device for a massager comprises an outer frame 10, one end of the outer frame 10 is provided with a drive motor 11, the motor shaft of the drive motor 11 is provided with an outer cylindrical surface cam 12, and the other end of the outer frame 10 is A sliding hole 101 is provided, and a telescopic sleeve 20 adapted to the sliding hole 101 is provided inside the outer frame 10. A rotary sleeve 21 is provided on the end of the telescopic sleeve 20 facing the drive motor 11, and the outer cylindrical surface cam 12 is located on In the rotary sleeve 21; the outer wall of the rotary sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com