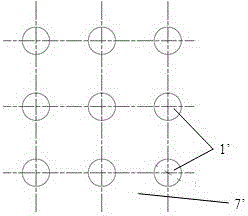

Measurement tool and measurement method of verticality of deep hole of tube plate

A technology of measuring tooling and measuring method, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of consuming the energy of inspection engineers, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

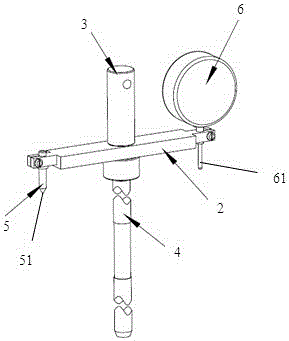

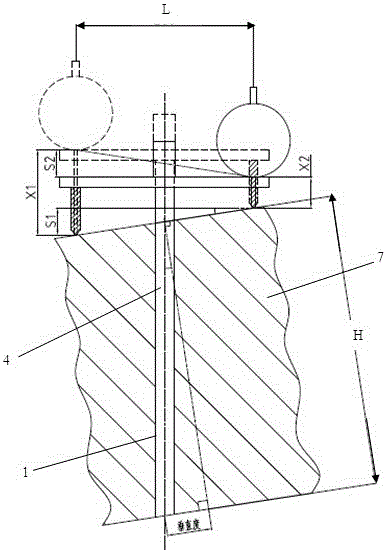

[0033] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0034] Such as figure 2 Shown; A tube sheet deep hole verticality measuring tool, which includes: bracket 2; handle 3, which is vertically arranged above the bracket 2; mandrel 4, which is vertically arranged below the bracket 2; thimble 5, It is vertically arranged at one end of the support 2, and the bottom of the thimble 5 is provided with a tip 51; the dial indicator 6 is vertically arranged at the other end of the support 2, and the bottom of the dial indicator 6 is provided with a measuring rod 61. The size of the mandrel 4 matches the size of the deep hole 1 to be measured, ensuring that the axis of the mandrel 4 remains coaxial with the axis of the deep hole 1 during testing.

[0035] In this embodiment, the size tolerance range of the deep hole 1 is Φ20.68 (+0.09 / -0.04). Due to the large number of deep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com