Density correcting method for interface floating ball type liquid level meter

A floating ball type and liquid level gauge technology is applied in the field of liquid level gauge calibration and density correction of interface type float ball type liquid level gauge, which can solve the problem that the interface type float ball type liquid level gauge does not give a calculation formula, etc. , to achieve the effect of solving the density correction problem and solving the calibration problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

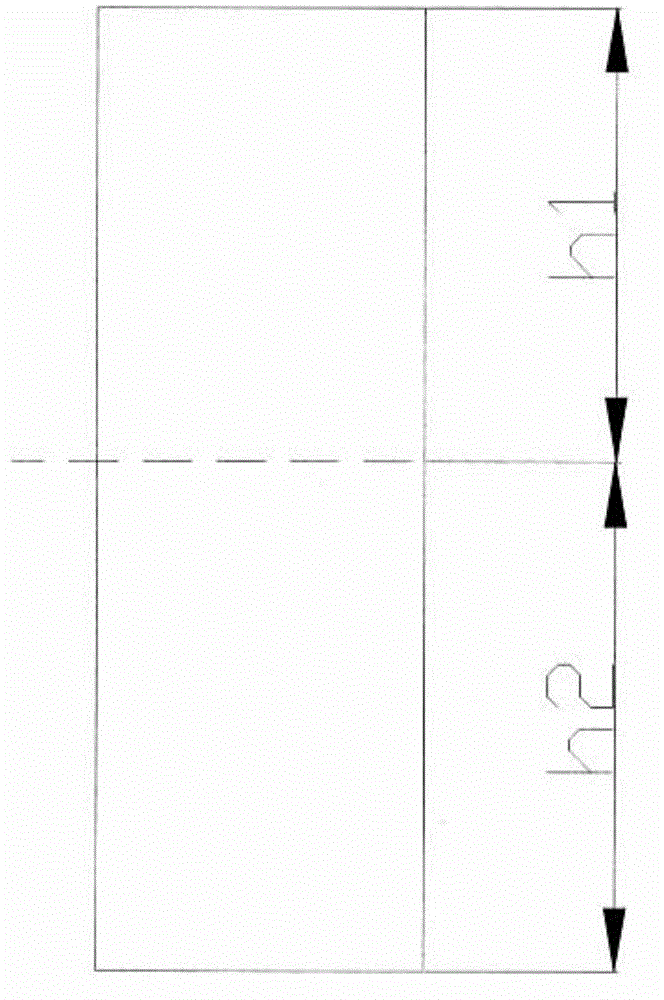

[0029] like figure 1 As shown, the present invention adopts the following verification steps:

[0030] The first step: verify or calibrate the measuring standard instrument:

[0031] The main measurement standards include: electronic balances, density meters, vernier calipers, measuring cylinders, etc. for verification or calibration to ensure that the measurement standards meet the relevant requirements of the measurement range and accuracy level, and ensure that they are qualified and valid;

[0032] The second step: weigh the mass m (kilogram) of the floating ball through an electronic balance;

[0033] Step 3: Use a vernier caliper to measure the diameter D (meter) of the cylindrical part of the floating ball, and calculate the radius R;

[0034] Step 4: Measure the volume V (cubic meters) of the float with a graduated cylinder;

[0035] Step 5: Use a density meter to measure the density ρ of the calibration medium water w (kg per cubic meter);

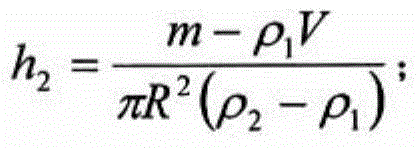

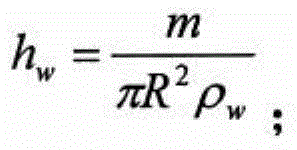

[0036] Step 6: List t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com