An intermediary bearing vibration signal collection method

A bearing vibration and signal acquisition technology, which is applied in the detection field, can solve problems such as difficult direct installation of sensors, low signal-to-noise ratio of fault signals, and difficulty in diagnosis, so as to improve the signal-to-noise ratio and facilitate follow-up monitoring and diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

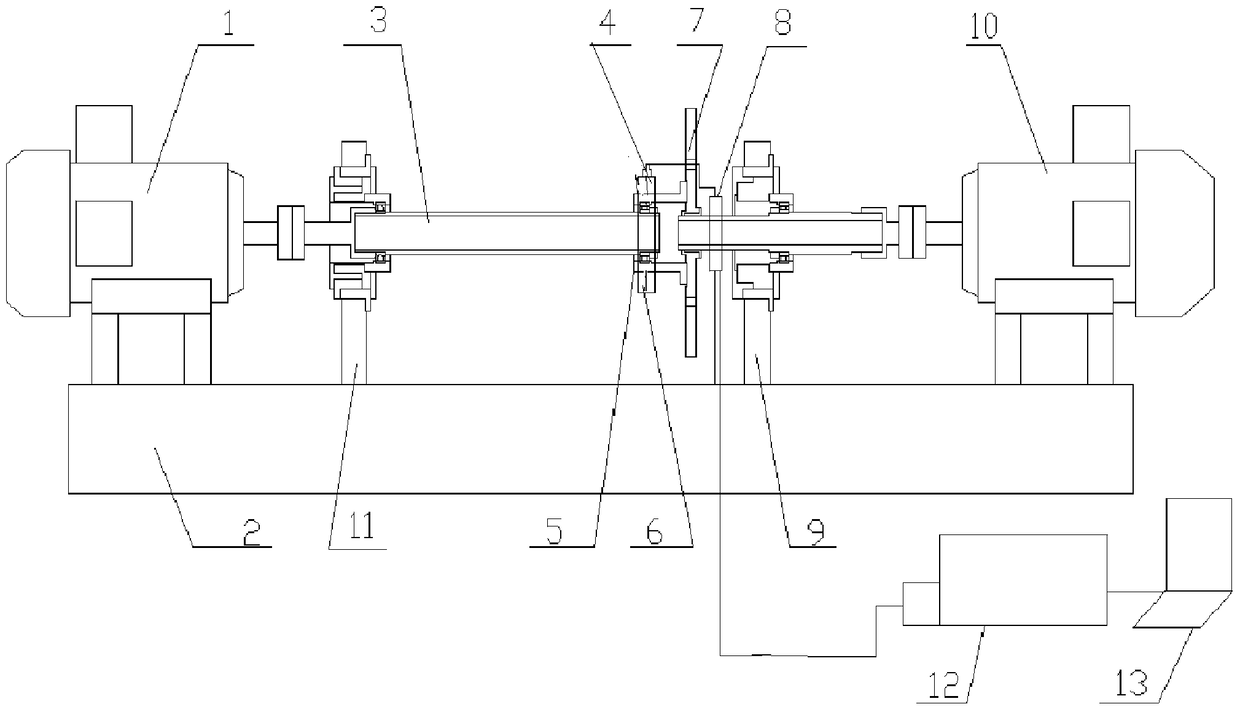

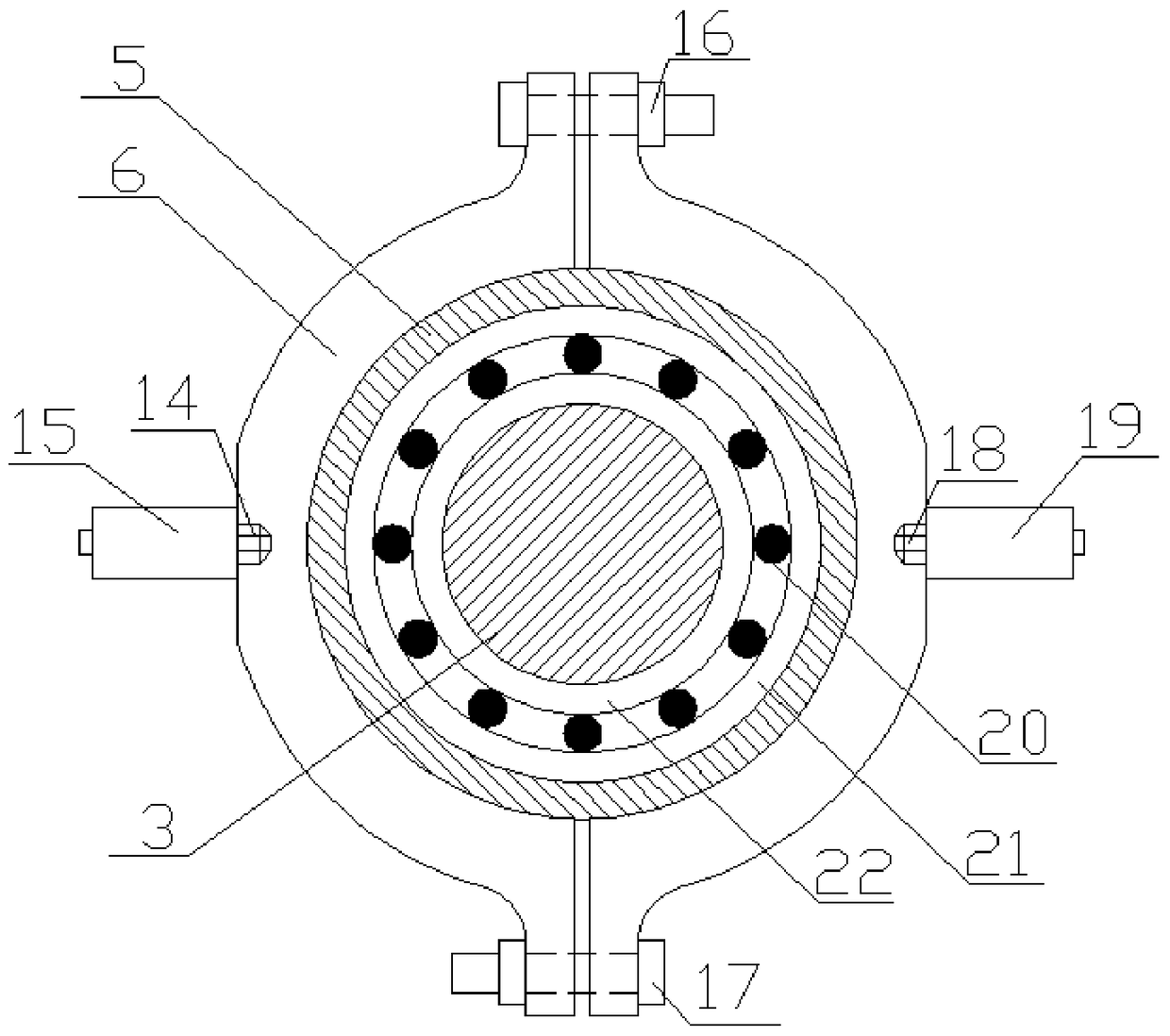

[0014] The present invention will be further elaborated below in combination with the accompanying drawings and the technical solutions of the description.

[0015] The invention discloses a method for collecting vibration signals of intermediary bearings, the working principle of which is as follows: the sensor installation buckle rotates synchronously with the high-voltage rotor shaft, the acceleration sensor is fixed on the sensor installation buckle through a threaded hole, and the lead wire of the acceleration sensor is connected to the outer ring of the electric brush At the connection point, the inner ring of the brush is fixed to the high-voltage rotor shaft by screws, and rotates synchronously with the high-voltage rotor shaft. The outer ring of the brush is fixed on the base 2 of the test bench by bolts, the leads of the outer ring of the brush are connected to the data acquisition board box 12, and the collected vibration signals are uploaded to the PC through the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com