Ventilated vacuum well for sewage tank

A ventilated and sewage tank technology, applied in the direction of sewage removal, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as large safety hazards, high input costs, and complex structure and functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

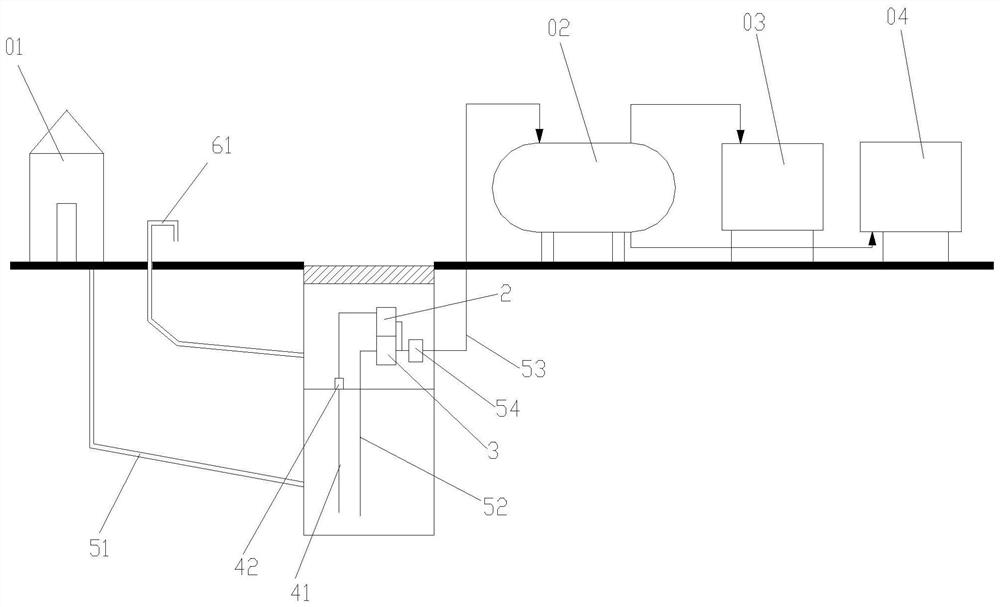

[0089] Such as figure 1 As shown, a sewage tank ventilated vacuum well, its application scenario is:

[0090] The ventilated vacuum well of the sewage tank is set below the ground as a temporary sewage collection and storage device, which will come from the sewage source 01 (such as rural bungalows, tile houses, buildings, cement houses, villas, and urban residential buildings, high-rise buildings, buildings, etc.) The domestic sewage (such as black water represented by waste water sources such as urinals and toilets, and gray water represented by waste water sources such as kitchen, washing and bathing) is transported to a remote sewage treatment station 04, and the sewage tank is ventilated vacuum A vacuum collection tank 02 and a vacuum pump station 03 are also arranged between the well and the sewage treatment station 04 .

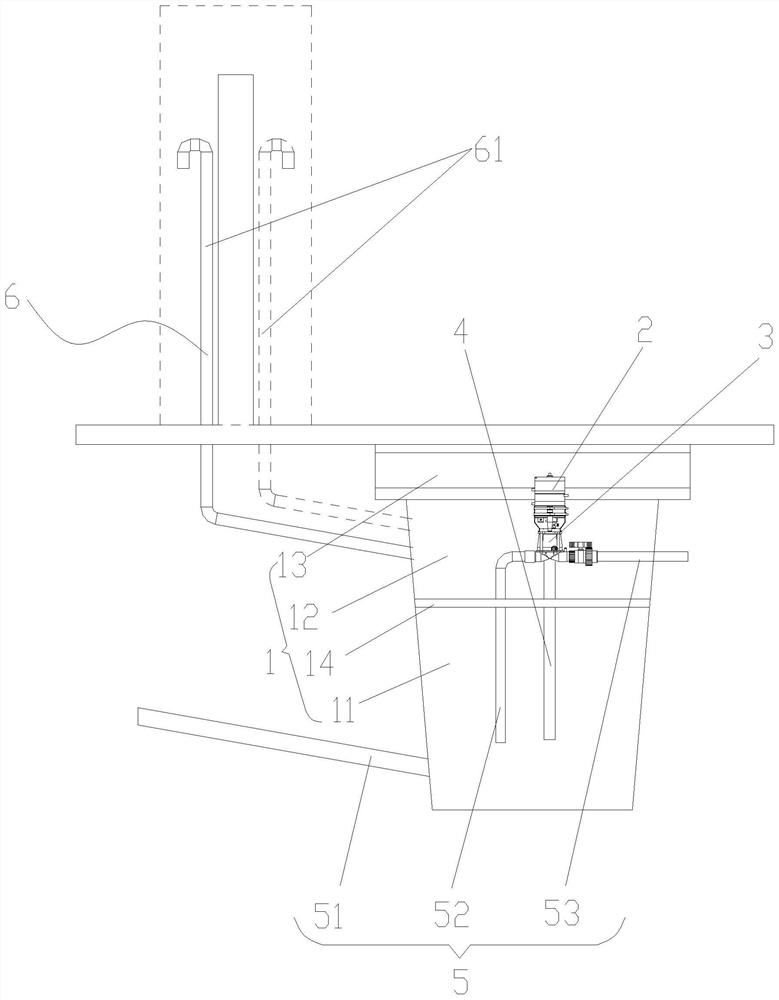

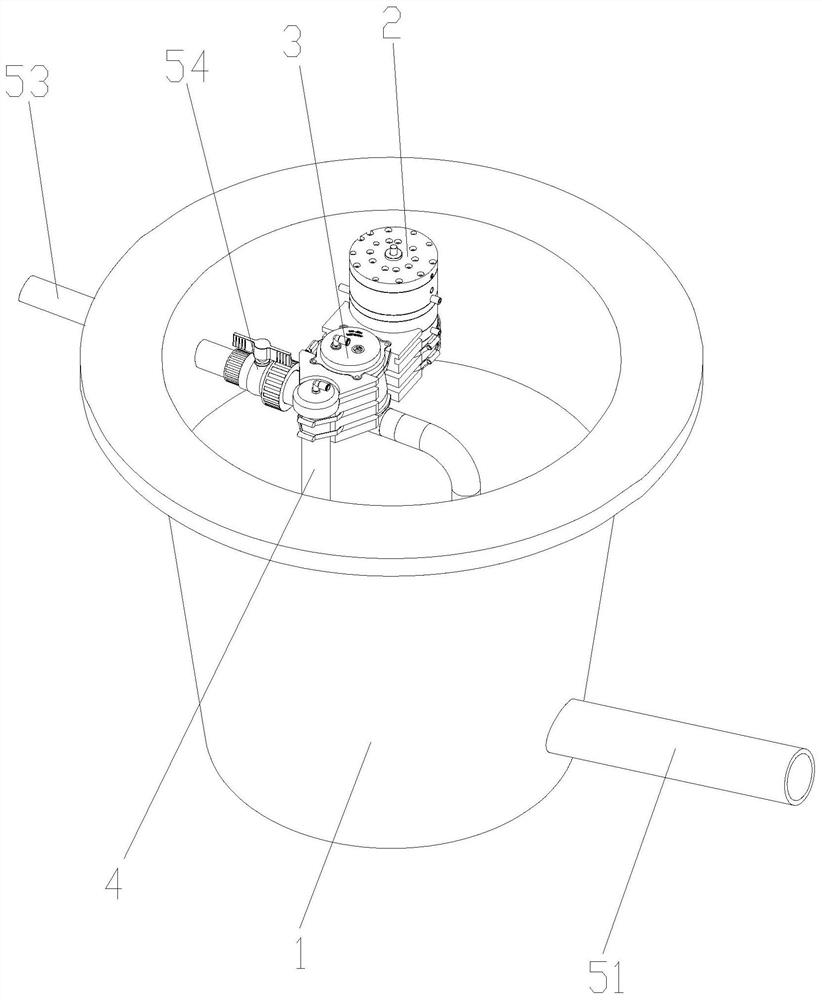

[0091] Such as figure 2 As shown, the sewage tank ventilated vacuum well includes a well body 1, a pneumatic controller 2 installed in the well bod...

Embodiment 2

[0113] Such as Figure 12 As shown, a sewage tank ventilated vacuum well, its application scene is the same as that of embodiment 1. In this embodiment, the way of laying the gravity sewage inlet pipeline 51 is to carry out gravity from the sewage source to the vacuum well according to the gradient of gravity drop. Pipe layout, if the distance is too large, a necessary number of lifting elbows 55 needs to be added therebetween. When there are lifting elbows 55, the sewage accumulated at the lifting elbows 55 will cause air in the ground ventilation pipe 61 near the building. If it cannot be effectively entered into the sewage chamber 11, the problem of water resistance will appear at this time.

[0114] The impact of the water resistance is as follows:

[0115] One, since the sewage chamber 11 and the equipment chamber 12 are configured in a sealed manner, the air above the sewage chamber 11 is in a sealed state; When the air is connected, the pressure of the air above the s...

Embodiment 3

[0123] Such as Figure 18 As shown, a sewage tank ventilation type vacuum well, its application scene is the same as embodiment 1 and embodiment 2, in this embodiment, such as Figure 19 , Figure 20 As shown, the liquid level sensor 4 and the pressure relief device 7 in Embodiment 2 are designed in one body, and the pressure relief device 7 is installed on the partition 14, as Figure 21 , Figure 22 As shown, its structure includes a pressure relief housing 71, a vent assembly 72 and a sealing assembly 73 arranged in the pressure relief housing 71, the lower end of the pressure relief housing 71 is provided with a pipe body 43 extending to the lower end of the sewage chamber 11; the liquid level The sensor 4 includes a liquid level circulation pipeline 41 and a liquid level sensor interface B42, wherein the liquid level circulation pipeline 41 is set through the pressure relief housing 71, and the liquid level sensor interface B42 communicates with the upper end of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com