Method for restraining torque ripple of surface-mounted permanent magnet synchronous motor by use of current harmonic waves

A permanent magnet synchronous motor, current harmonic technology, applied in torque ripple control and other directions, can solve the problems of inaccurate current zero-crossing detection, complex algorithm, wrong compensation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

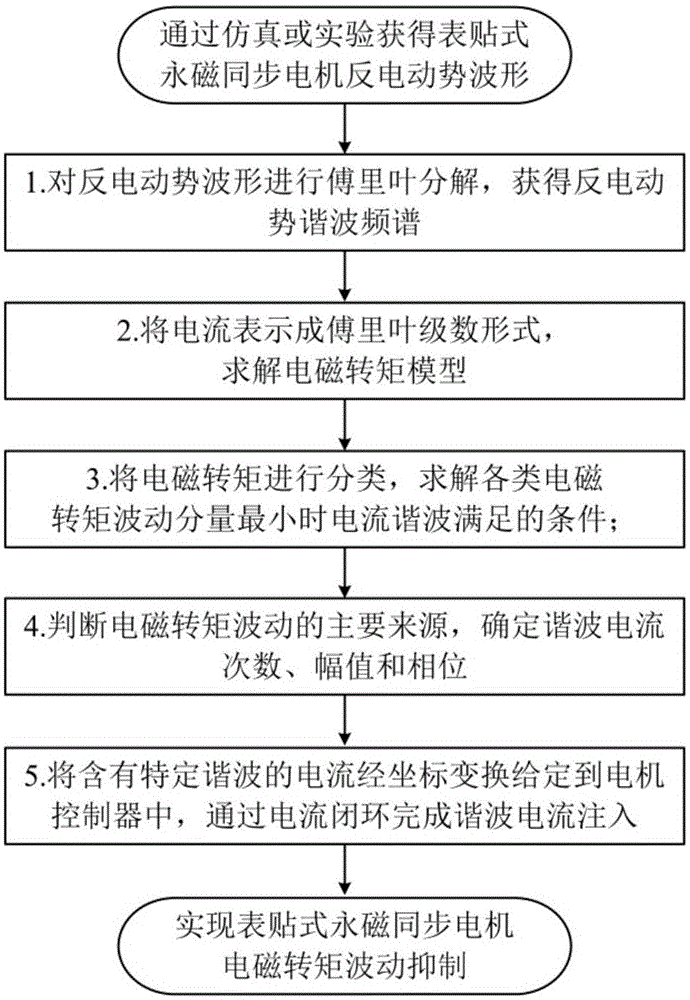

Method used

Image

Examples

Embodiment 1

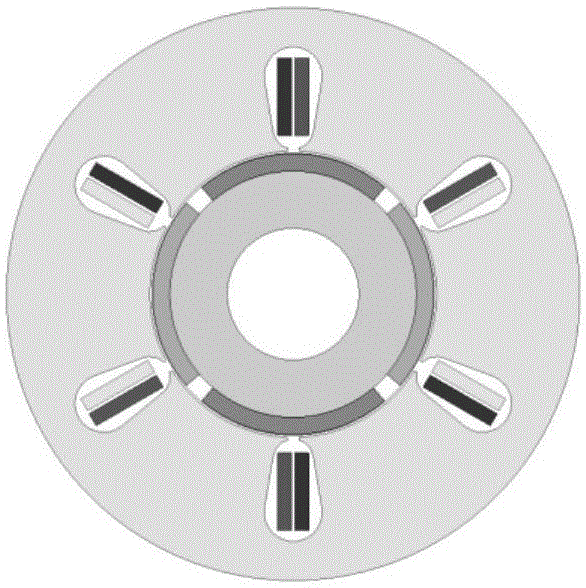

[0111] 101: figure 2 It is a finite element model of a 4-pole 6-slot double-winding surface-mounted permanent magnet synchronous motor. The rated frequency of the motor is 50Hz, the rated speed is 1500r / min, and the effective value of the rated current is 3A, that is, I 1 =4.24A. Surface-mounted permanent magnet synchronous motors usually use i d =0 control mode to control, that is, ψ 1 =0.

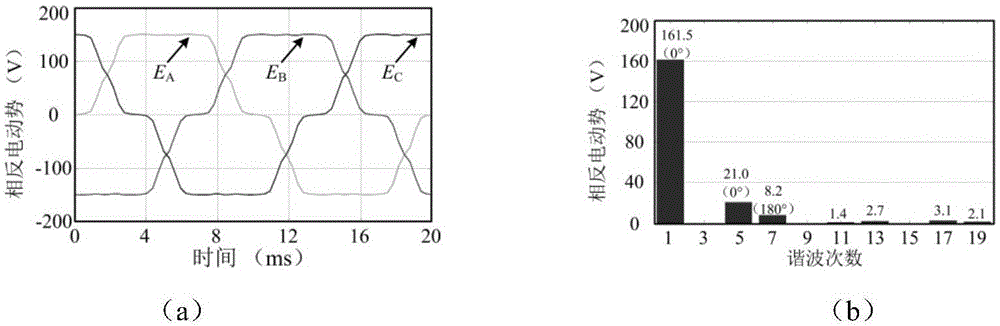

[0112] 102: The three opposite electromotive force waveforms of the motor can be obtained through finite element simulation, such as image 3 (a). The spectral distribution of each harmonic of the back EMF and the amplitude of each harmonic are further obtained through Fourier transform, such as image 3 (b).

[0113] 103: By image 3 (b) It can be seen that the 5th and 7th harmonics in the back EMF waveform are the main harmonics, and the amplitudes of other harmonics are all less than 2% of the fundamental amplitude, so other harmonics can be ignored, focusing on the 5th and 7t...

Embodiment 2

[0122] 101: Figure 5 It is a finite element model of a 4-pole 12-slot single-layer winding surface-mounted permanent magnet synchronous motor. The rated frequency of the motor is 50Hz, the rated speed is 1500r / min, and the effective value of the rated current is 3A, that is, I 1 =4.24A. Surface-mounted permanent magnet synchronous motors usually use i d =0 control mode to control, that is, ψ 1 =0.

[0123] 102: The three opposite electromotive force waveforms of the motor can be obtained through finite element simulation, such as Image 6 (a). The spectral distribution of each harmonic of the back EMF and the amplitude of each harmonic are further obtained through Fourier transform, such as Image 6 (b).

[0124] 103: By Image 6 (b) It can be seen that the 5th and 7th harmonics in the back EMF waveform are the main harmonics, and the amplitudes of other harmonics are all less than 2% of the fundamental amplitude, so other harmonics can be ignored, focusing on the 5th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com