Centre device with various shapes of heads capable of being quickly replaced

A head and thimble technology, applied in tool holder accessories, tailstock/top, turning equipment, etc., can solve the problems of slow replacement, low applicability and high cost, and achieve the effect of reducing cost and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

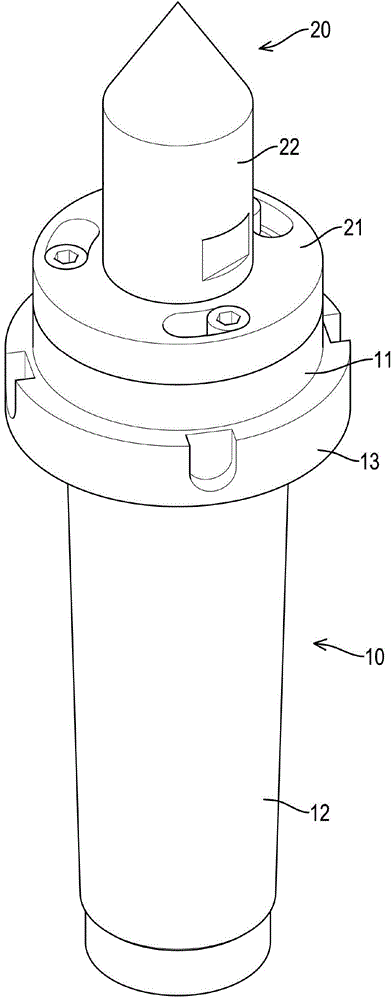

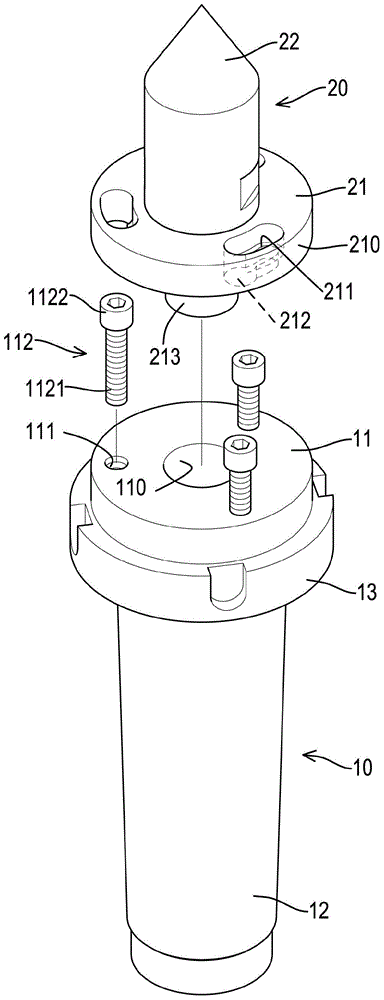

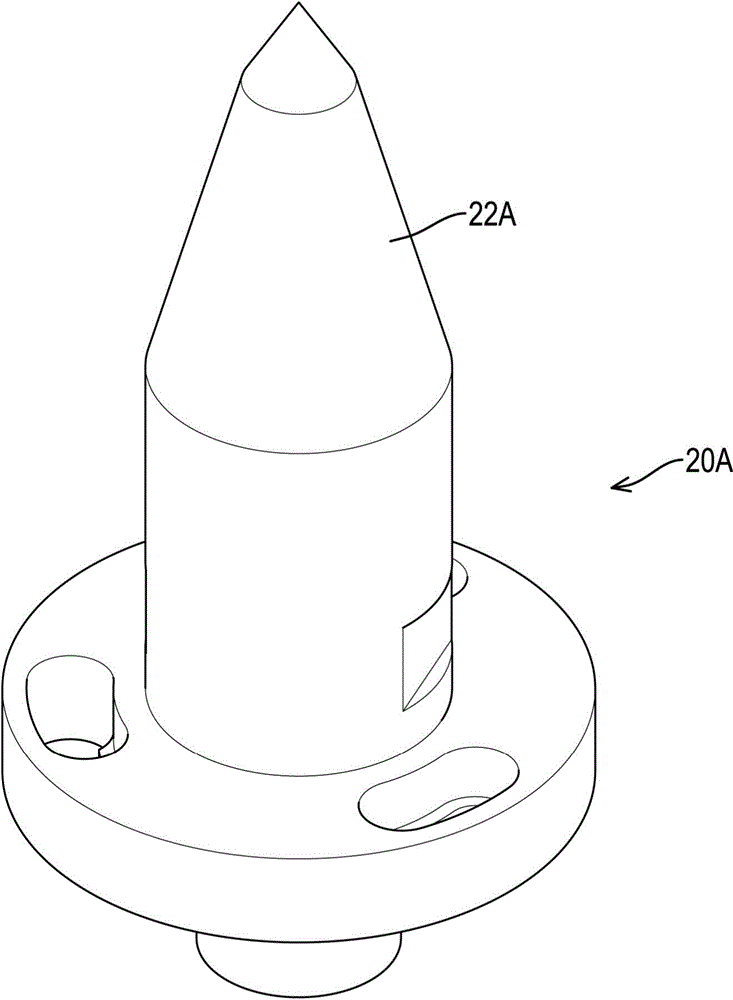

[0044] The present invention is a thimble device that can quickly replace heads of various shapes, please refer to figure 1 and figure 2The first preferred embodiment shown is a fixed thimble and includes an abutment shank 10 and a head replacement part 20 .

[0045] Such as figure 1 and figure 2 As shown, the centering handle 10 is a handle body extending along the front and rear directions, a head 11 is formed at the top of the centering handle 10, and a tapered handle 12 is formed on the lower side of the head 11 , the centering handle 10 is provided with a nut 13 adjacent to the outer periphery of the head 11, and an accommodating portion 110 is provided on the top surface of the head 11 at the axial center position. In this embodiment, the accommodatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com