Method for repairing fractured transmission shaft

A repair method and transmission shaft technology, applied in the field of mechanical maintenance, can solve problems such as low investment, short repair period, and unrepairable transmission shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

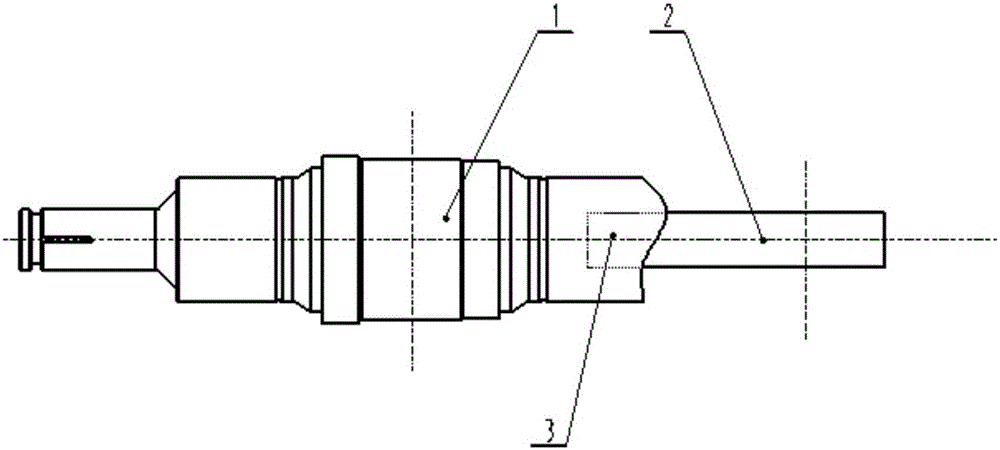

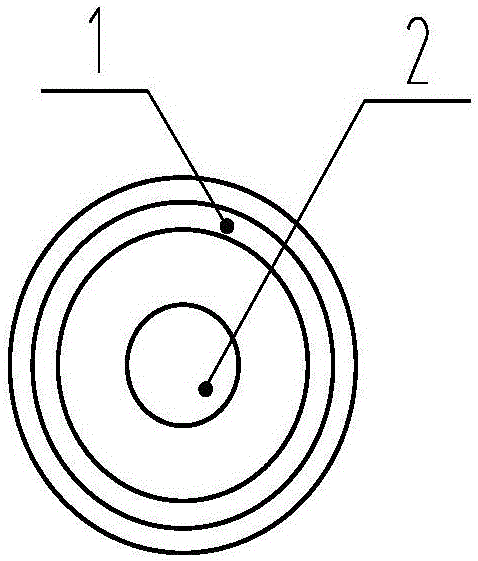

[0015] A repair method after a drive shaft breaks, such as figure 1 and figure 2 shown, the axis of rotation dimensions mm x 4000 mm, minor axis size mm x 900 mm. Rotary axis machining center hole mm, the short axis and the central hole of the rotating shaft adopt an interference fit.

[0016] The repair method after the above-mentioned transmission shaft is broken is as follows:

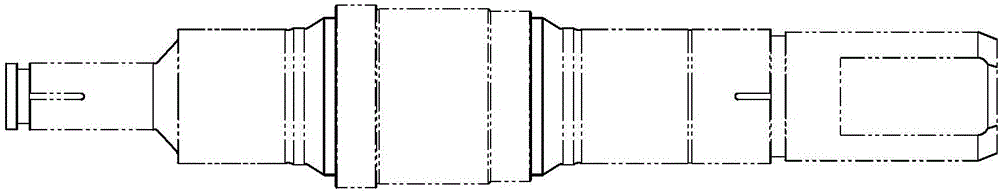

[0017] Machining the center hole 3 in one end section of the disconnected drive shaft 1, install the short shaft 2 in the center hole 3, adopt a large interference fit between the center hole 3 and the short shaft 2, and then carry out surfacing welding on the outside of the short shaft 2, and surfacing welding to the transmission After the original size of the shaft, finish machining according to the drawings to restore the mechanical properties of the drive shaft. The repaired drive shaft is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com