Repairing Method of Underwater Inverted Cracks Using Magnetic Mortar

A repair method, an inverted technology, applied in the repair of infrastructure, construction, infrastructure engineering, etc., can solve the problems of strength (unable to guarantee shear resistance, difficult to repair crack edges, waste of resources, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

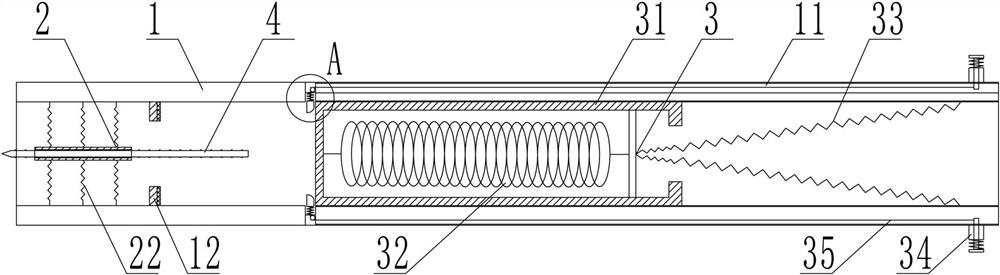

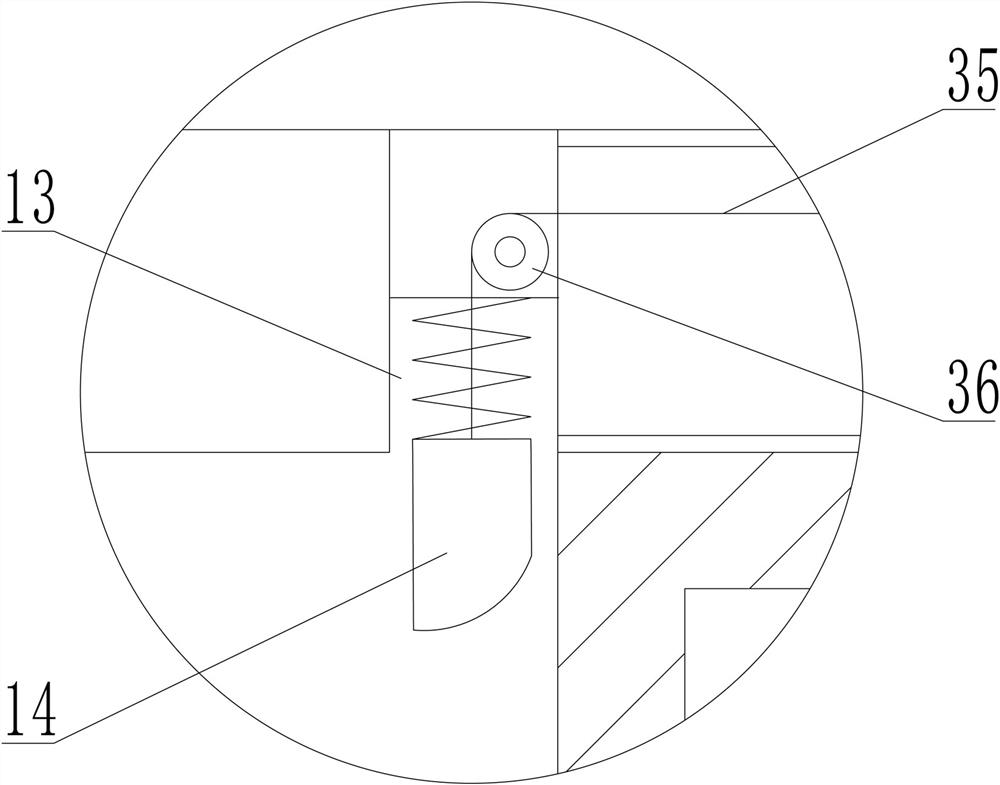

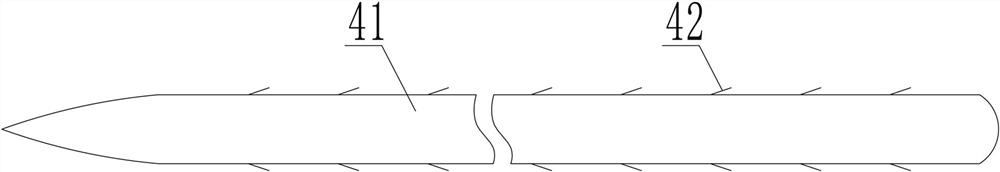

[0049] like Figure 1~Figure 9 Among them, a repair method for repairing an underwater inverted crack using magnetic mortar, the device used in the repair method includes a guide cylinder 1, a clamping mechanism 2, a launching mechanism 3 and a magnetic nail 4; the clamping mechanism 2 and the launching mechanism 3 is located in the guide cylinder 1, the clamping tube 23 of the clamping mechanism 2 clamps the magnetic nail 4, and the blocking block 12 and the slider 14 are arranged between the clamping mechanism 2 in the guide cylinder 1 and the launching cylinder 31 of the launching mechanism 3 , the blocking block 12 is connected and fixed with the inner wall of the guide cylinder 1 , one end of the slider 14 close to the launch cylinder 31 is slidably matched with the chute 13 on the inner wall of the guide cylinder 1 , and the slider 14 is flexibly connected with the launch button 34 of the launch mechanism 3 . The structure is simple. When in use, by arranging a clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com