Helicopter dedicated damping device

A vibration-damping device, a technology for helicopters, applied in the directions of fuselage, aircraft parts, transportation and packaging, can solve the problem of narrow vibration-damping bandwidth, and achieve the effects of simple structure, reduced driving fatigue, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

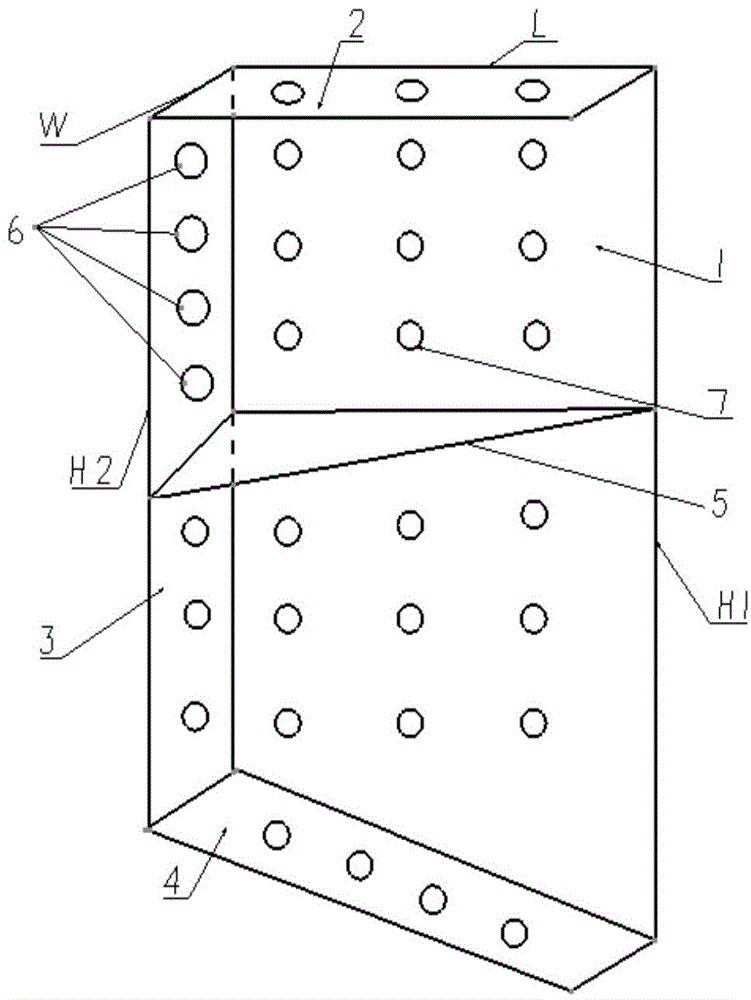

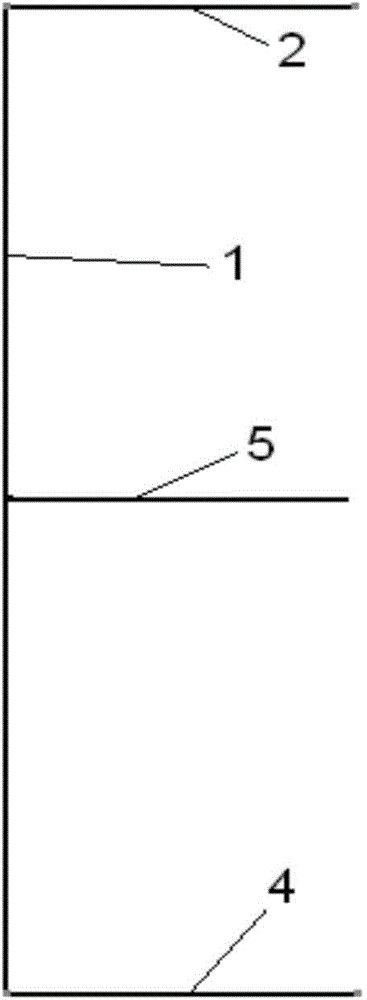

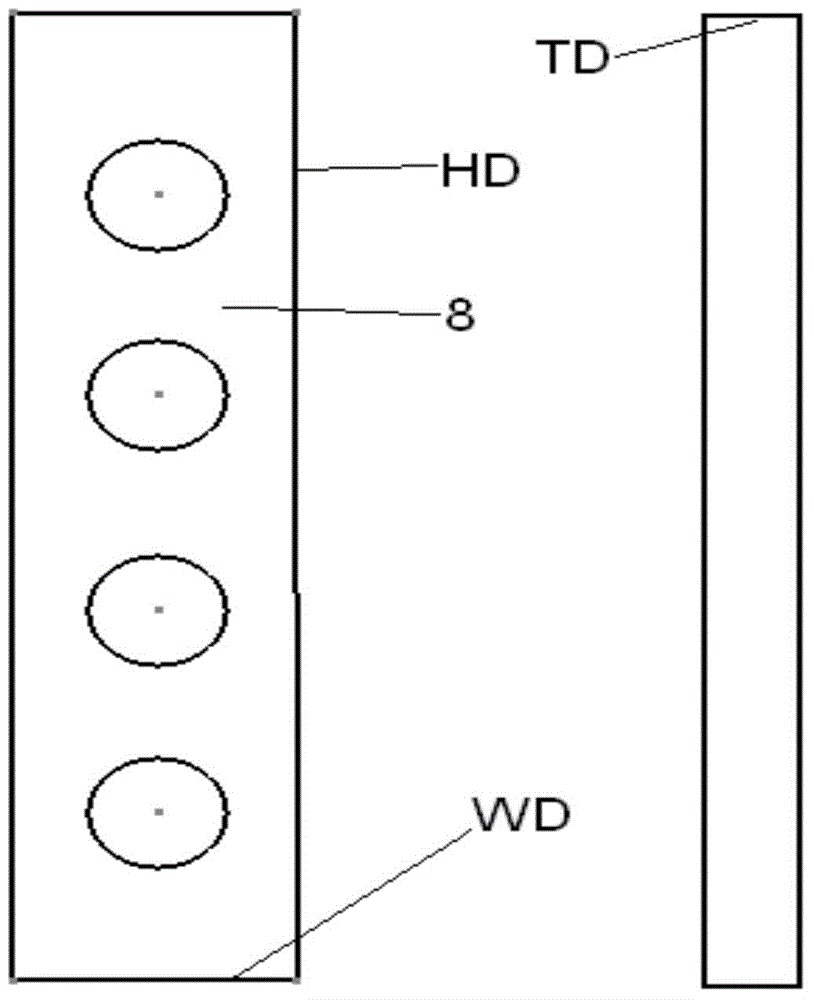

[0028] 1. Manufacture the vibration damping device according to the design drawings, material: 7010-T7451-δ25, standard ASNA3098.8870; wool size: 200×100, see the attachment for specific dimensions figure 1 , attached figure 2 , attached image 3 .

[0029] 2. The installation process of the vibration damping device is as follows:

[0030] 1) The vibration damping device is connected with the web 10 of the frame 1 and the side beam edge 11 with the connecting bolt 6, the connecting rivet 7 and the gasket 8; it is connected with the upper edge of the fuselage longitudinal beam 9, the lower edge of the Longitudinal beam web 14, floor 15, connect with connecting rivet 7. See attached for specific installation location Figure 4 .

[0031] 2) The side distance of the rivet is 7-8mm, the spacing is 18-20mm, the side distance of the bolt is 10-12mm, and the spacing is 18-20mm.

[0032] 3. Flight verification. A vertical acceleration sensor is arranged at the driver's pedals, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com