Fuel pump with acoustic isolation

A fuel pump and solid-borne sound technology, applied to fuel injection pumps, fuel injection devices, liquid fuel feeders, etc., can solve problems such as noise and interference, and achieve the effect of eliminating noise and avoiding the transmission of solid-borne sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

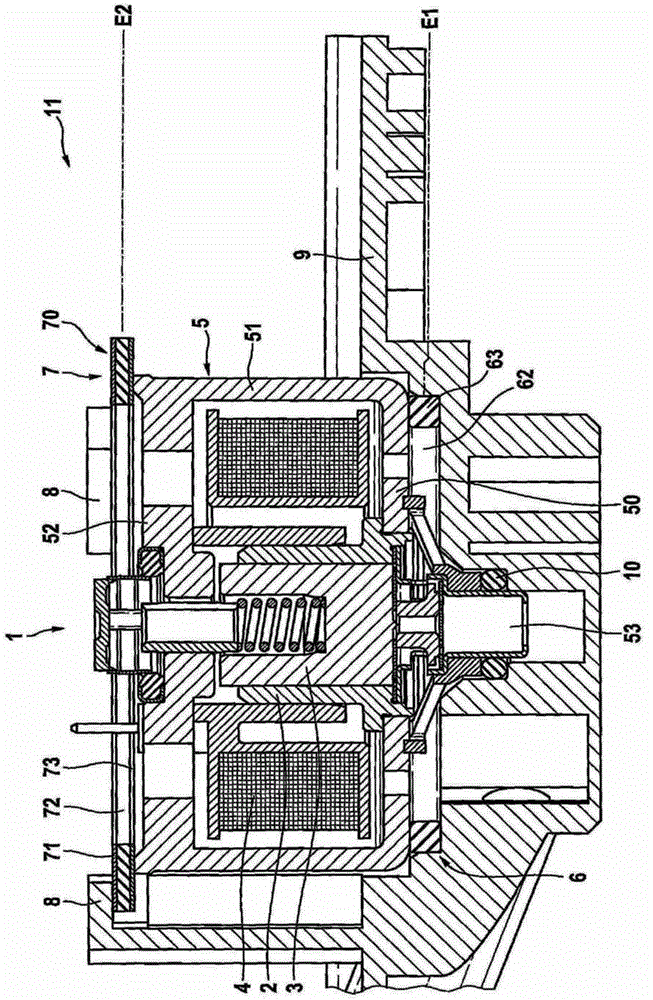

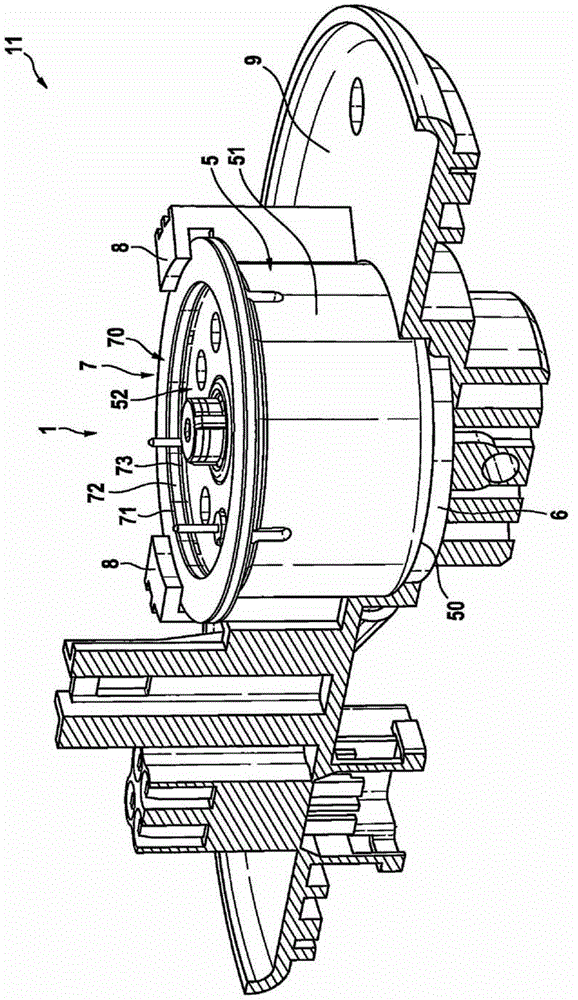

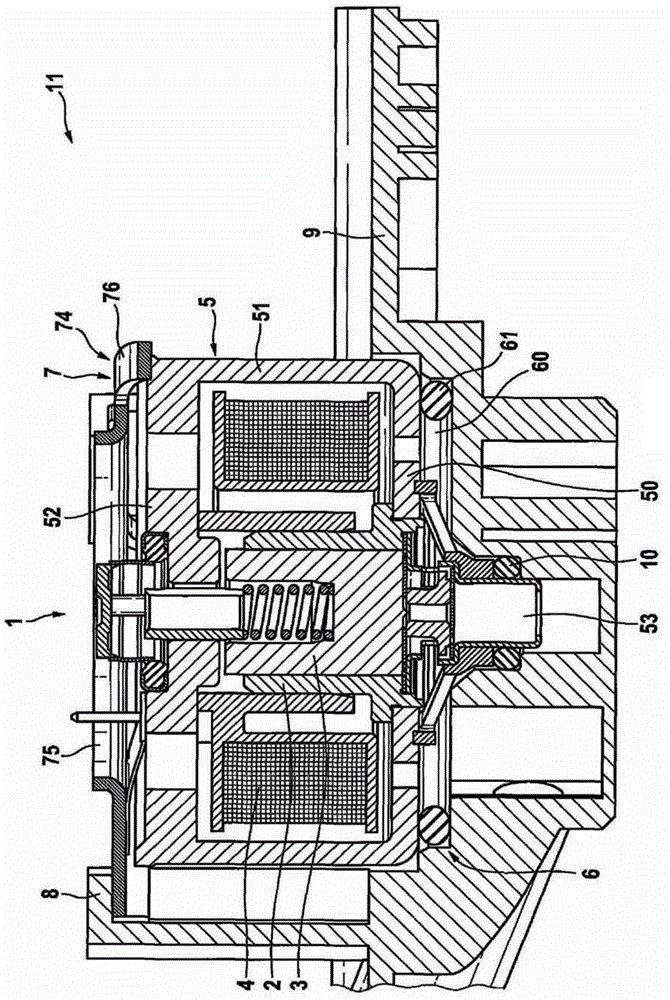

[0024] Refer to the following figure 1 and 2 A fuel pump 1 or a fuel pump arrangement 11 according to a first preferred embodiment of the present invention will be described in detail.

[0025] as from figure 1 It can be seen that the fuel pump 1 according to the invention comprises a cylinder 2 , a piston 3 arranged in the cylinder 2 , an actuator 4 for operating the piston 3 and a housing 5 . According to the invention, a first damping element 6 and a second damping element 7 are arranged on the housing 5 in order in particular to prevent the transmission of structure-borne noise.

[0026] The housing 5 is substantially pot-shaped with a base region 50 and a wall region 51 , the first damping element 6 being arranged on the base region of the housing 5 and the second damping element 7 being arranged on the wall region 51 of the housing 5 . In particular, the second damping element 7 is arranged at the free end 52 of the wall region 51 of the housing 5 .

[0027] Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com